Turning Turning Action!

I've been turning door knobs for cabinets on and off for forty-five years to date. That's what I did yesterday and a little over the weekend. It's a useful skill for a furniture maker of course, so I learned fairly early on in my working.

Handy to have a stock of door knobs in and best to do a few at once. Turning small and useful parts has always been stock in trade for me as it would be for most furniture makers in times past. Table and chair legs, spindles for chair backs, rails, arm supports come in a matter of minutes as do an infinite range of knobs you can't buy online or in the big box stores. From the simplest shapes to complex coves and beads that are limited only by the mind alone.

I had several poplar offcuts from the leaning wall shelf I built as a recent project for woodworkingmasterclasses not too long ago. Poplar is an unusual wood. I used the white grain that transitions from the light and bright sapwood before it develops its mineralised inner heartwood where wide bands and narrow streaks greet one another to create untold deeps of rich and diverse colours characterising poplar. It is indeed one of those ideal woods we furniture makers enjoy. It has consistent density across the bands of sap- and heart-wood. A nice density that responds well to the cutting edges of skews and gouges of every type and yields features reminiscent of maple.

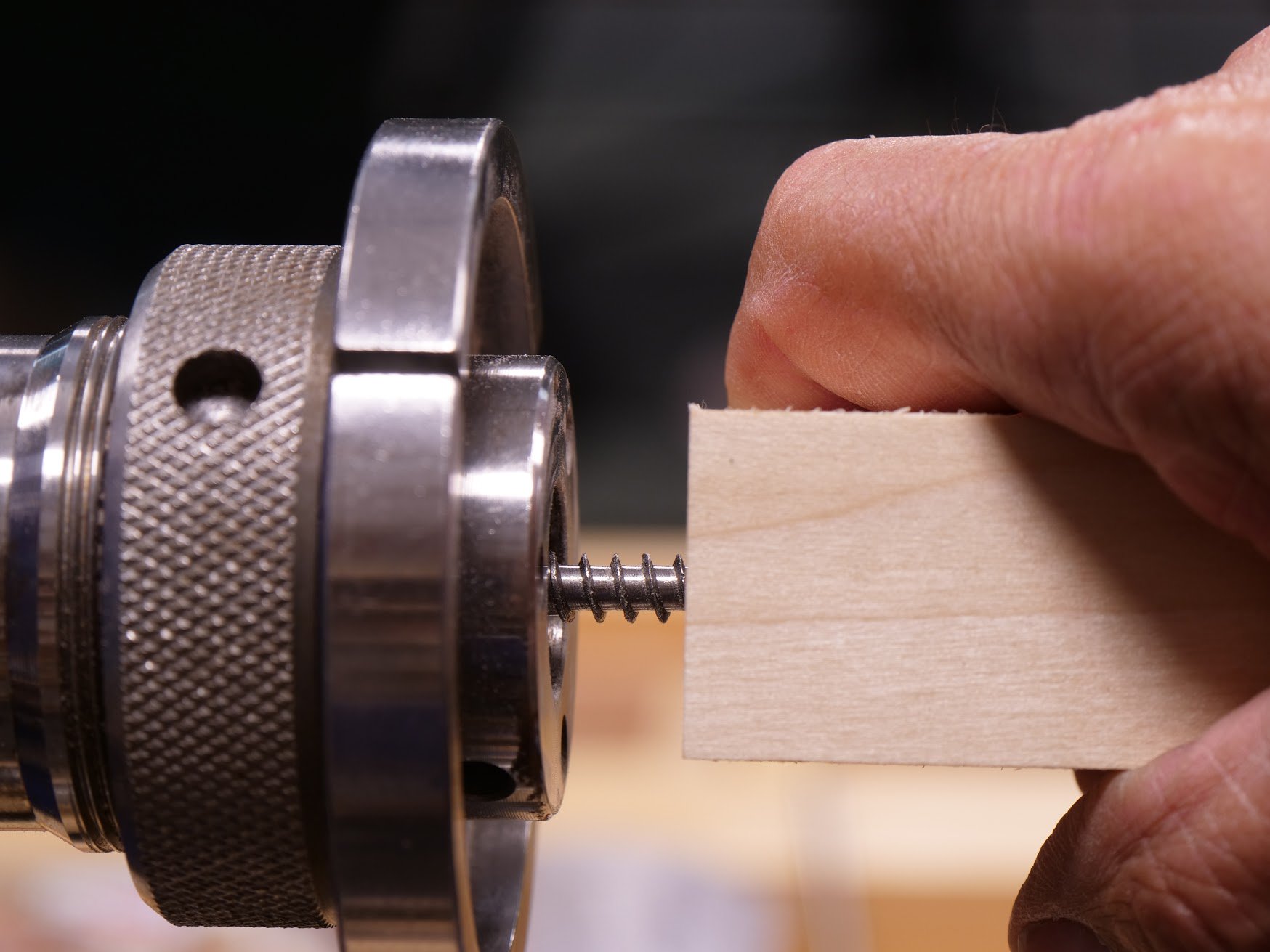

Poplar stains exceptionally well and you can use colouring from low coat milk and chalk paints instead of stains to develop any colour you want if that's your preference. I will keep these knobs as they are in a jar now and can take them one by one to make mahogany coloured knobs or ebonize them to a jet black that defies detection from the real McCoy. It takes about five minutes to turn a cabinet pull silky smooth including the finish. Small components are immediate gratification and very DIY. You don't need a big, heavy or commercial lathe to turn them and mini lathes work just fine. I picked my lathe up for £60 from a car boot sale a few years ago and then found a tray of interchangeable chucks that give me all the variations I will ever need. It's unlikely that I will turn bowls and such for a living again so heavy duty is unnecessary. This lathe does 24" between centres but I can rig it for any length I ever want by removing the tails stock and bolting head and tails stock to a board or a bench top.

Tomorrow I am filming turning door pulls and door knobs. I am ready for any turn of events.

Comments ()