Waterborne Finishes—Experience Them

One thing I'm learning about more modern ways is that we should reconsider how we actually consider things rather than just accept or dismiss them. I suppose I am asking myself, "What lens are you looking at this through, Paul?"

In times past I have changed my drink from say coffee to an alternative hot beverage, perhaps to a drink sold as a good coffee substitute. I drank the drink for a few weeks and actually liked it as much as coffee, but a good coffee substitute it was not. After a while I realised that I just liked the drink for what it was. It was a nice drink but it was more an alternative taste and drink rather than something that replaced my enjoyment of an early morning coffee. In the end I drank both and enjoyed two substantially different drinks. My perspective had gradually shifted. At first I had disliked the substitute because it seemed to me as some kind of, well, fraud. That was because I was told it didn't taste too different than coffee so my correlation delivered the thought that it was 'just like the taste of coffee coffee'. Sometimes manufacturers do the same when they offer carob as an alternative to chocolate or Mansonia, (a tropical African hardwood evergreen) as Walnut. Whereas carob and Mansonia are fine enough natural products in their own right carob is not chocolate and mansonia is not walnut either. Neither of them are the same as nor even a good substitute for the real McCoy no matter how how you slice it, pulp it or reconstitute it.

So here we are living in the era of waterborne finishes for wood. I have sprayed it successfully to a textureless surface, brushed it and padded it on and ended up with slightly different textures. Over the years we have seen clear polyurethanes and varnishes take more of a backseat to waterborne finishes. Do waterborne finishes replace varnishes? Well, no, not really. Perhaps not at all. Are they any good? The answer from me is that I like them but we are not really comparing apples for apples as were the points in case above. If you use waterborne finishes you can of course compare them to other finishes you know. Whether you can compare them as products of equal measure is truly questionable. My looking into waterborne finishes has been interesting. Where I ended up was in the same place as carob and chocolate and coffee and chicory-based products. They are not one and the same.

Over the years I have chosen different wood finishes for different reasons and different protective qualities, strengths such as durability and such. Few products replace varnish for outdoor use for instance, but oil-based polyurethane works well for indoor work like furniture, and exposed cabinet work used in millwork, doors, stairways and such. In recent years we've been given an alternative product, a water-borne poly or some other such thing under different names but essentially made for the same purpose, the same reasons from the same or similar enough constituents to be one and the same. In this week's use of finish I chose a water-borne floor finish. I applied 4 base coats followed by three top coats with sanding after the first and third coats to 250 grit. I then applied a fourth coat which remained unsanded but was steel wooled with fine 0000 steel wool before the application of a soft wax furniture polish applied again with 0000 steel wool and buffed out with a soft cloth.

My garage workshop is dry and warm bordering on warmer but comfortable enough. That means that the coats are dry to hardness in 20-30 minutes and touch dry in 10. Because the first coat gets absorbed the most and fastest I can usually sand after the half hour just fine. This sanding takes care of the raised grain associated with water based products. Whereas you can damp-rag the surface to raise the grain first, I haven't really found this to offer much if any advantage. It is a common flaw to think that because the waterborne finishes are made up primarily of water that the applying the finish in wet or humid conditions is not a problem. It is! Usually, as with many finishes used for wood, the surface skins over first and seals in moisture that results in bloom beneath the surface. It stays there until you remove it and often that means sanding back down to below the bloom. Choose your day. Also, don't fall foul by using a fan to dry out the surface too as this results in the same blooming issue. Let nature take its course, be patient. Remember that this a is a finish that you can apply with 6-7 layers over a few hours. Sometimes as little as 4 hours for 7 coats.

Even though I consider myself skilled with a brush, the waterborne's seem always to hold a trace of brush that textures the surface acceptably and add a certain hand-made extra I particularly like yet the feeling after light waxing with furniture polish is as smooth or smoother than silk.

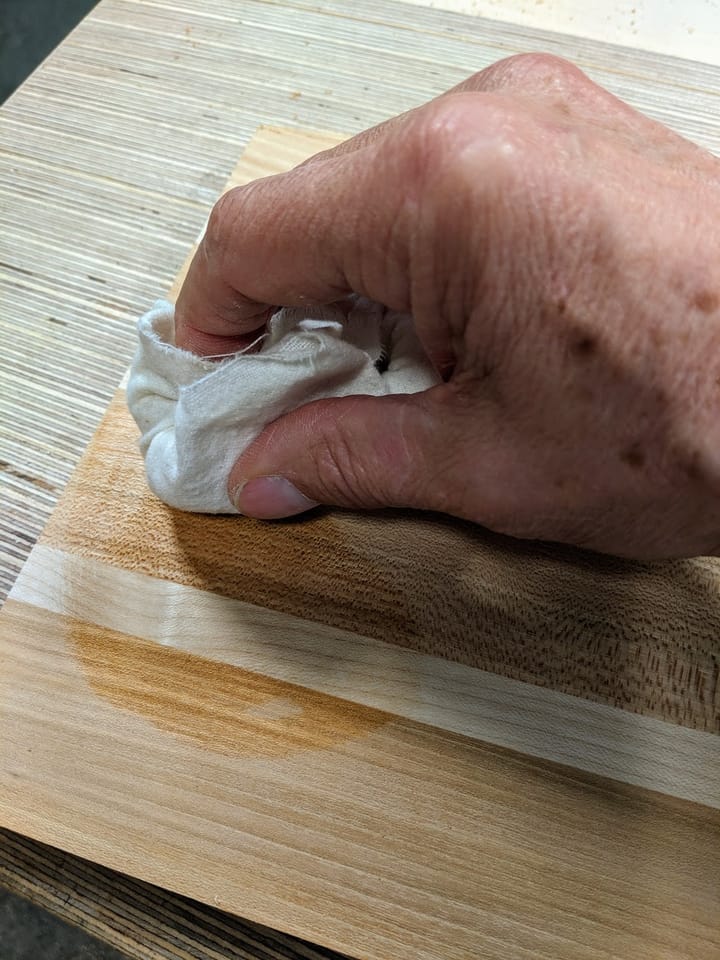

The system I use is not at all rigid and there are reasons that you might want to change the application procedures to better suit the surface you want. As an instance you may possibly want to even sand all the way between every coat rather than build up the layers. I have not found this to be of advantage but I could see that if you wanted a thicker overall finish you could use say10 coats rather 4 or 6. Another option is to use a power sander like a random orbit sander to take the multiple layers down to a completely matt and untextured finish. These are just thoughts but they are also options. Generally I have settled on 4-7 or so coats and built them up in half hour intervals. The last coat I leave over night to cure and then surface buff with the steel wool. I then use the steel wool to apply the furniture polish because that keeps the polish nice and even and use a soft polishing cloth to buff out the finish for the sheen I so like. In the project shown I used a sating finish.

Comments ()