Which Man-made Boards to Use?

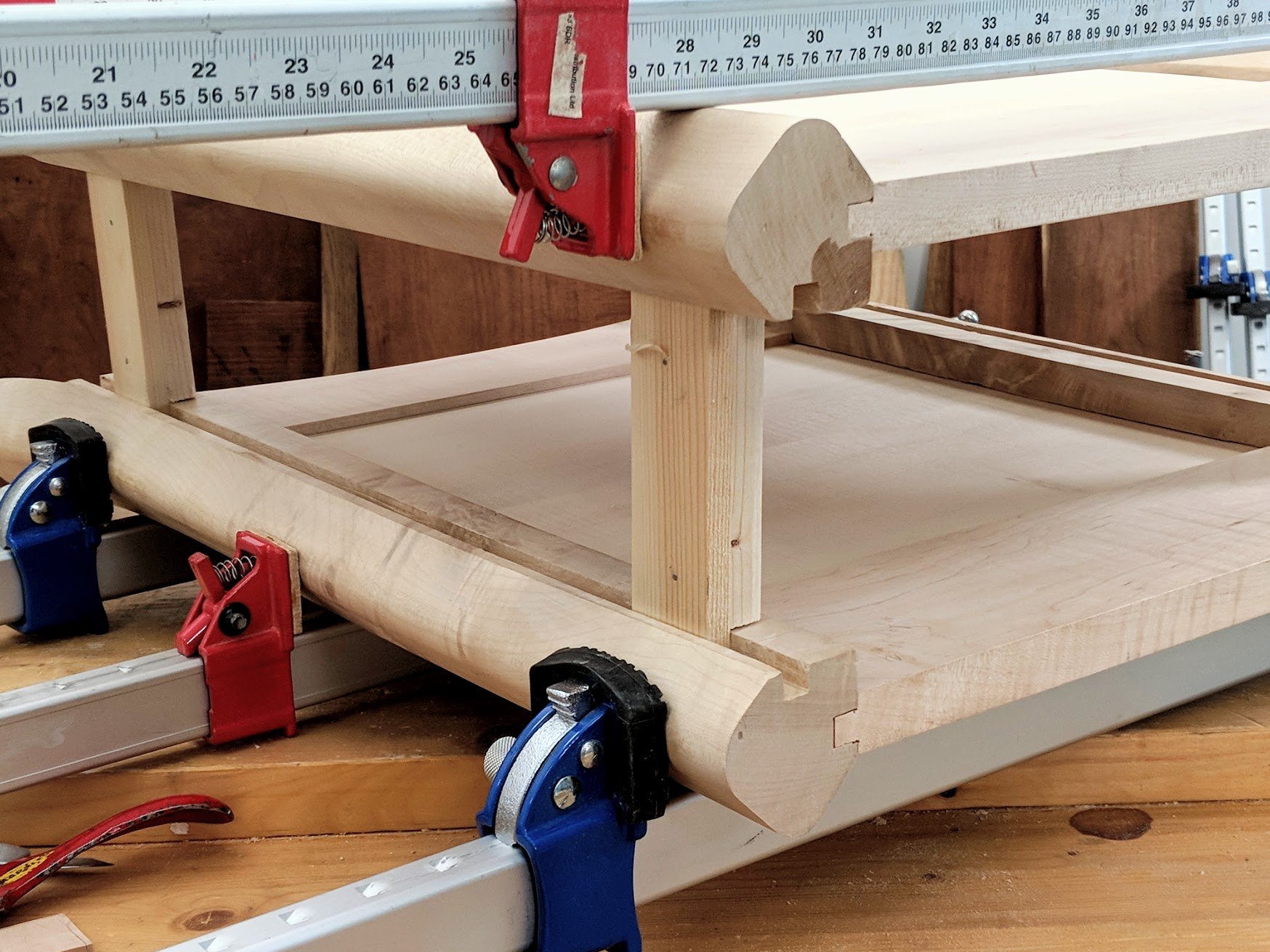

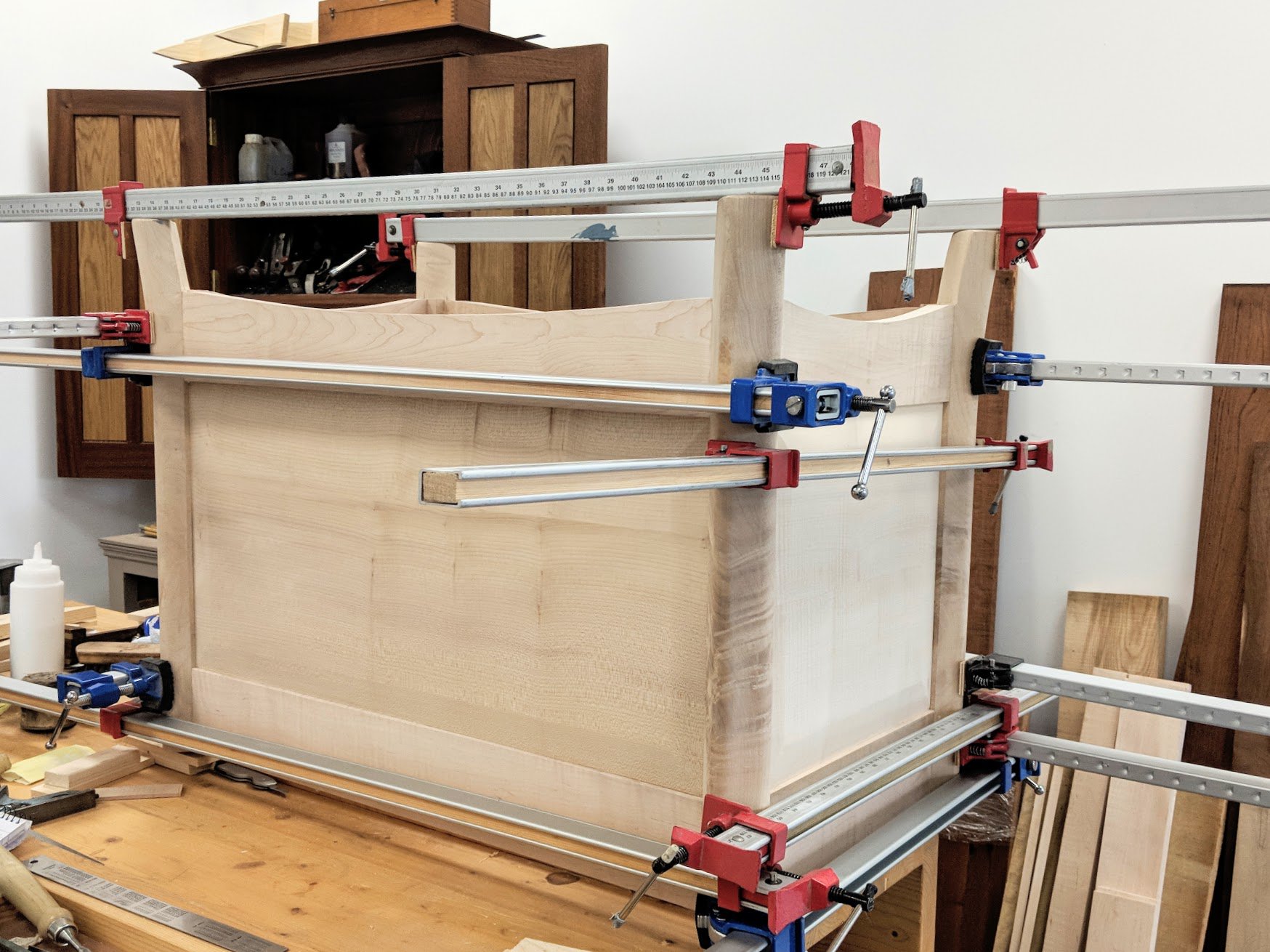

I've been enjoying making the second blanket chest and the challenges of the glue up. because of the struggles I came up with a more foolproof way for gluing up and aligning everything so that the glue up could be done as a two step process. This took off the pressure of a large, single endeavour.

The long axis glue-up did have some issues making my strategy all the more worth the extra steps I took to avoid comications.

The wood has been stunning and the challenges of different wood types switching from softer hardwoods within the Acer (Maple) species meant little was as predictable as I'd like, but now the main superstructure is all grooved, panelled and jointed I'm enjoying bringing the whole to a close. But it's this that brought me to the point of this post. Moving into my garage space has made me think about the materials I will use. Storage, shelves, shelves and panels to my new workbench and such are within my radar right now. What's been considered in the past I am not considering the same today. Even so, pressed fibreboard (chipboard) pegboard, hardboard (masonite USA) and MDF are non-negotiables, they're out. Real wood and plywood on the other hand are my two primary choices because of their proven technology but then more than that they suit my personal preference for working wood with hand tool methods even though I will and do use machines for some of my work.

As it is with many things, predictability often escapes us when we work with real wood and perhaps especially with using hand tools. Planing the surface of curly maple or birds eye maple needs special care, sharp edges and a swift shift in direction in a split second. Wood expands and contracts and in its natural condition rebels when you least want it to. Glue it down hard and it shrinks and splits. Then it cups and bows when left unconstrained when left free.

That's why commerce and so called professionals like to use MDF. MDF may lead to the kind of characterless products hiding under the guise of some sort of 'Scandinavian' styling free (or freed) from classicism, but in manufacture, simple lines, squared off edges and square blockiness means that many designs are risk free for the makers. Used appropriately, MDF has it's place, I know that. It doesn't shrink, is remarkably stable, is fully machinable and it's relatively cheap to produce.With the right hardware it can hold up. It's just not the kind of material I like having around. All in all, for those of us enjoying real woodworker it's not quite so easy a material to work with either. You can't work it too well at all with hand tools. MDF demands high speed machines and cutters to work it and all of that means heightened danger with machines, waste and dust. Even with sharp hand tools such as planes chisels and saws, MDF seems always to 'mushroom' under the pressure of just about all hand tool cuts and thus making a negative product. Drive screws into it and somehow it develops its own type of fibrous powders and screws seem always to strip out even under low torque. Screwing into the edge at any point results in the fibres parting too. I rarely use moulding on my work that I can't make with a #4 or a simple moulding plane. I own a hand held power router and skilsaw, a jigsaw too, but somehow the MDF and pressed fibreboard produce a dust and powder I just cannot accept as invasive substances in my life. Both of these materials were engineered as sheet products designated for industrial mass-manufacture. As I never mass make anything, it seems I am destined to continue my life not using MDF or pressed fibreboard. I feel fine about it.

So my plywood is in and so too much of my wood. It's a question of organising myself now. My first garage project is going to be wood storage.

Comments ()