Axminster's #80 Cabinet Scraper-Uh Oh!

...How Could They Get It So Wrong?

Periodically we just get it wrong! Oh, Axminster, why did you stop so short for a ha'p'orth of tar? No instructions on the scraper set up, wrong cutting blade bevel angle, single cutting edge not two? The box claims, "Superior Trade Quality" and then "Woodworking Planes" and the scraper is very much not at all a plane of any type, not related at all to the plane category of tools and should never be confused as such. Even though the header on their webpage for this tool says...

Axminster Rider No. 80 Scraper Plane—

...if you are new to woodworking, THIS IS NOT A PLANE!

What to do? I decided not to leave it alone and allow confusion to set in for the generations new to woodworking so I'll correct it here because it's often true that manufacturers won't get to it or won't get to it soon enough. I added a link to this blog post on their website review section too, so that there will be no confusion as the staff at Axminster and their demonstrators obviously know nothing about this tool.

Here's a video to watch about the cabinet scraper AFTER I fettled it to get the flawed concepts out. Please read the full blog though before you purchase.

Well, so much to say!

So what did go wrong? Well, we know that we can get things wrong, but this comprises a series of perhaps smaller issues leading to the bigger issue of poor information/communication and product quality control. It shows how little they know about 80 cabinet scrapers or that they handed it off to the manufacturers in Asia or that they just don't care. What's obvious is that customer/user care is at am all time low. The flaws with their #80 scraper would seriously jeopardise any new woodworkers chances of success with the tool and would totally confuse them. Perhaps they should check their product control department and then too involve their research department (if they have one) a little more. This is surprising on one hand because they have been the industry suppliers in the UK for so long, but then on the other hand they are not in any way the hand tool experts they might claim to be as is the case with so many hand tool catalogue supply companies I suppose.

Firstly, I assume Rider to be an Axminster brand that Axminster UK owns because they are the only outfit with sales outlets for Rider hand tools. I believe the Rider plane range is either made by or follows the same knock-off manufacturer as the Quangsheng range except that the Rider plane models copy the Irwin Record model lever cap, as the standard lever cap iron has been replaced with a knurled setting screw instead of the lever cap iron. That said, forget the scraper being a plane or in their Rider plane category because they should not knowingly recategorise tools and create confusion by naming a #80 scraper as a plane. But I am willing to put this down to ignorance rather than an intensional step to mislead.

At first glance the Rider #80 looks identical to any of the #80s ever made, but it may look better as far as finish quality and specs go. I must say that their packaging has to be near the very best yet! No corrugated cardboard here. And if you do like or have need of stowing tools in their boxes and with padding too you need look no further on that front. The one we received came in a black coloured box lined with shock absorbing foam cushioning on all six sides. I find boxes irritating as I like all of my tools near to and ready to go, but I do understand the need for boxes if the tools are not in full time use. I use mine every day all day, whereas most people don't and taking precautions is important. Of course we are looking a bit deeper than the box, aren't we?

So just where did Axminster go wrong?

Apart from the misnomer as a plane, when I looked at the Rider pictures it wasn't so much the overall appearance of the box, the name or the tool itself that grabbed my attention but seeing what looked like a thicker cutting iron. I had never seen a thick iron on a scraper anywhere so I wanted to see how well a thicker iron performed over the standard thinner one. Would the thick iron be difficult to flex-bend to task as this is what the tool depends on for creating and adjusting depth of cut. As I pulled the scraper from the box my first impression was that it was a tool of quality. I had read two reviews on the Axminster site referencing the tool, one fairly good and the other fairly bad. Neither of them mentioned the real issues that intrigued me so.

OK! The boxing up impressed me, I'll admit that, but when I opened it up there was about zero information on the tool at all, no instructions, no description of what I'd bought. So I had to ask myself why was the cutting iron so thick?

Then I asked myself why was the blade made up of two alloy types with one being laminated to the other. there was no mention of this anywhere on their site or in the booklet that came with the tool. Why was the main body of steel hardened so hard a Bahco file just glided off it but the laminated cutting edge so much softer. It had to be some kind of mistake!!! You see if the cutting edge steel of the blade is softer than the main body steel then filing the bevel becomes an impossible task but the #80 scraper relies on draw filing with a flat file for establishing the bevel and then sharpening and restoring its cutting edge ready for turning. In other words, the bevel of the main body steel prevents the file from removing the existing developed cutting burr and the ability of developing any new bevel that creates the turned cutting edges. Simply put, it is a very flawed concept. 1. The laminated two-steel type blade has steel that's too hard to sharpen with a file and because one is harder than the other the bevel cannot be sharpened with just a file makig it expensive to sharpen using diamond plates.

Number 2 flaw: The cutting bevel is ground at the standard 25-degree angle as is standard for the ground or primary bevel for all edge cutting tools like planes, spokeshaves, chisels, drawknives and such. Plane blade bevels have nothing near the concept of the scraper blade because in no way is the #80 cabinet scraper a plane! As any woodworking enthusiast knows, the bevel on #80 scrapers is always ground and honed at as near to 45# as possible because it is not intended to push the tool plane like with the bevel cutting edge used in a slicing cut but the cutting edge is a highly refined turned edge that in effect forms a long and turned hook. Effectively turning a 30 degree hooked edge means the edge fractures and breaks off under the pressures of the work because the bevel angle creates to thin a hooked edge. Three or four strokes and you have lost the edge.

False concept number 3: If the whole blade was made from just appropriate O1 tool steel it would have been just perfect. I did not understand the hardened body steel and the laminated edge. It was totally unnecessary and renders the simplicity of conventional sharpening to be a very difficult task being possible only with power equipment or diamonds.

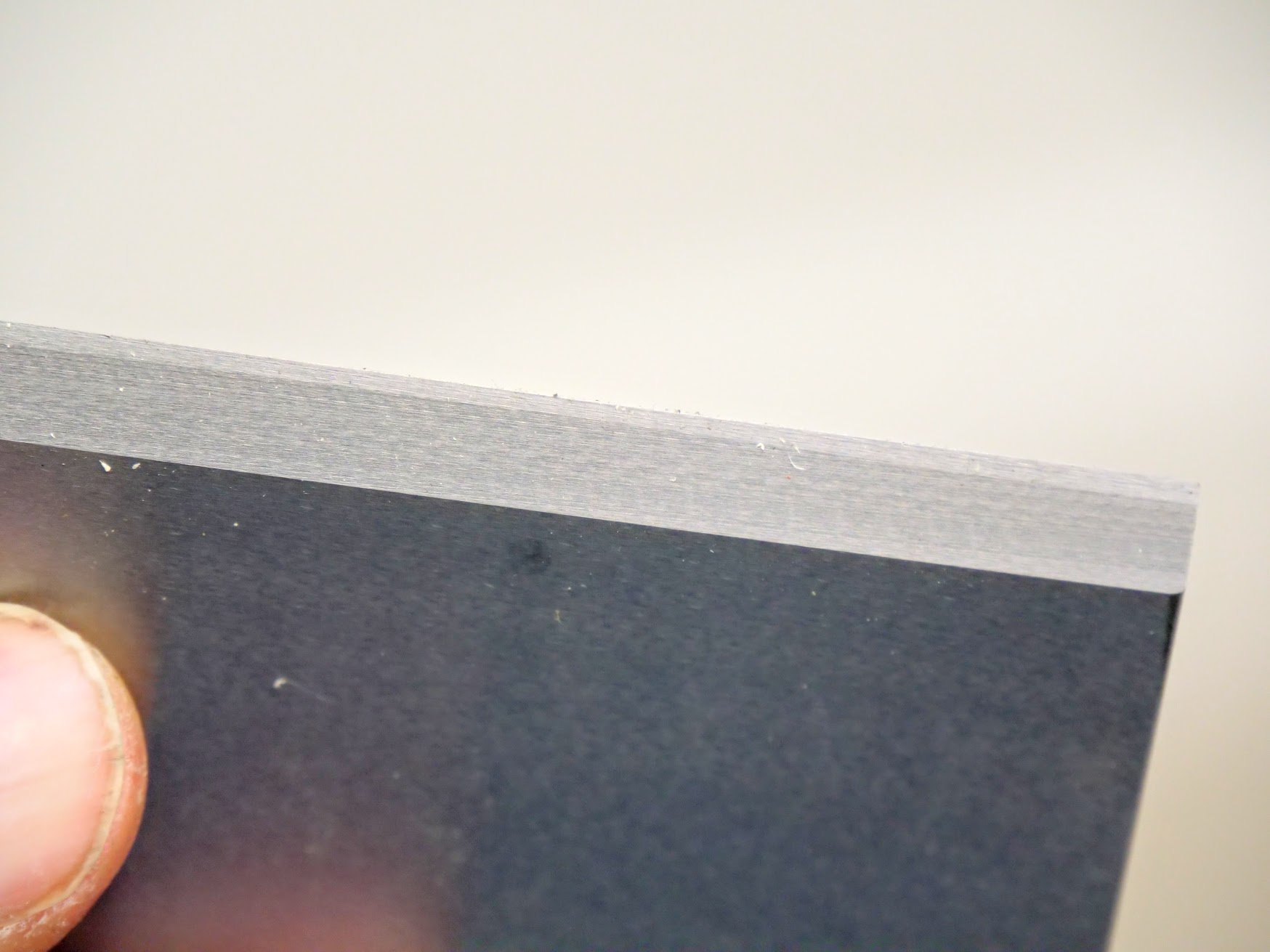

What I did like about the Rider version was that you could load the blade in a honing guide for a fully honed out flaw-free 45-degree bevel, which you cannot do with conventional thinner blade because they bend when pressure is applied to the sides of the iron via the blade holding setscrew for holding the blade securely. The thicker iron keeps the blade straight so the bevelled cutting edge is straight.

I liked the price. Not expensive for this quality of manufacturing. £28 is about just slightly over one third the Veritas scraper price. The thing that frustrated me the most was that new woodworkers would not have the working knowledge to see the problems straight off. They would most likely see themselves as the problem or not realise they could make it work. They might also think that the tool generally, i.e. the #80 is just not good tool. With no in-package information available with the tool it is understandable they would see themselves as the problem. The thickness of the steel on Record and Stnley as standard is around the 1mm plus side. The Rider is an impressively thicker iron at 2.87mm.

The image below shows my working with the tool on mesquite but I tested it on beech, poplar, oak and it scraped well. Mesquite is a hardwood and a hard, dense-grained wood that's almost twice as hard as oak. Poplar on the other hand can be difficult to scrape.

On a more positive note

The component parts to the tool are made from good materials. Whereas the sole is not dead flat, I have never found that to be a real issue as long as it's close enough as the tool cannot produce a truly flat surface because the blade is bent or curved for it to be functional and adjustable.

These two images show how the retaining bar bends away from the blade when the two thumbscrews are tightened. It's not much but it allows the blade to bend when the adjuster thumbscrew applied pressure to the other side of the blade, bending it against the retaining bar. When the blade is locked in place and the thumb-screw adjuster is tweaked to adjust for depth of cut both retainer bar and blade bend very nicely together at the same time.

I will test the tool out over the next few weeks but I did get it sharp and I liked the way it performed after corrective work.

1: You can fix the issue of too hard a steel by using diamond plates to abrade the bevel, but that makes the price overly expensive if you don't actually own diamond plates. Generally the very best and least expensive tool used for this is a decent 10" Bahco flat file. £10 for ten years of scraper sharpening.

2: You could regrind the whole bevel to 45-degrees on an electric grinder but this is a sad apology for what should have been done right. But it will be fine to make a 45-degree bevel to a narrower edge say 2-3mm wide and then, as you resharpen, get it down with each successive sharpening you do.

Conclusion: What I liked about the scraper was that at first glance the quality was high. Brass knurled nuts, body casting was good too, smooth and consistent, nicely painted and such. The retaining bar was very much more than adequate, so my overall feeling was good, very good.

It's such a shame to see what happened here happen. I was sad to have to give a negative review to what should be potentially a good and improved version of the standard #80 cabinet scraper but I cannot recommend buying the scraper with such poor attention to the details that really matter. Until Axminster takes care of its issues I've outlined clearly above you should consider whether buying it anyway will help them come to terms with the issues. Of course if you already have a diamond plate for honing it you can correct the bevel issue. You might even consider making your own cutting iron from O1 or A2 steel but that's more work than seems practical.

It saddens me that any new woodworker would buy it and not know exactly what the problems are and that it wasn't them that was the problem but the tools. Amazing that Axminster probably knows nothing of these issues as yet. Hopefully they'll hop to it quickly and rectify the problems by automatically recalling or issuing replacement cutting irons to those who've bought it.

I ordered a Veritas scraper blade as a replacement and it fits and works fine so perhaps a poor reconciliation is to not use the Rider blade and buy the £11 alternative which brigs the overall cost to around £40.

Comments ()