Plywood at the Victoria & Albert—A London First

Don't miss it. Make a trip to the V&A London. You will love it. More than that, there are dozens of other exhibits to broaden your perspective with. Hannah and I had an educational visit planned and this week it all came together when we explored to exhibits, the Plywood Exhibit and the Furniture Exhibit.

I don't think any of us can or indeed should be dismissive of plywood. It is truly a marvellous material, one worthy of its place in the entrepreneurial hierarchy of invention. Understanding its past will help us to trace an unravelling path into its mass-manufacturing present. It may well reach back to two or more millennia, but it's more its worth in our culture this past 100 years that will be of greater interest I think.

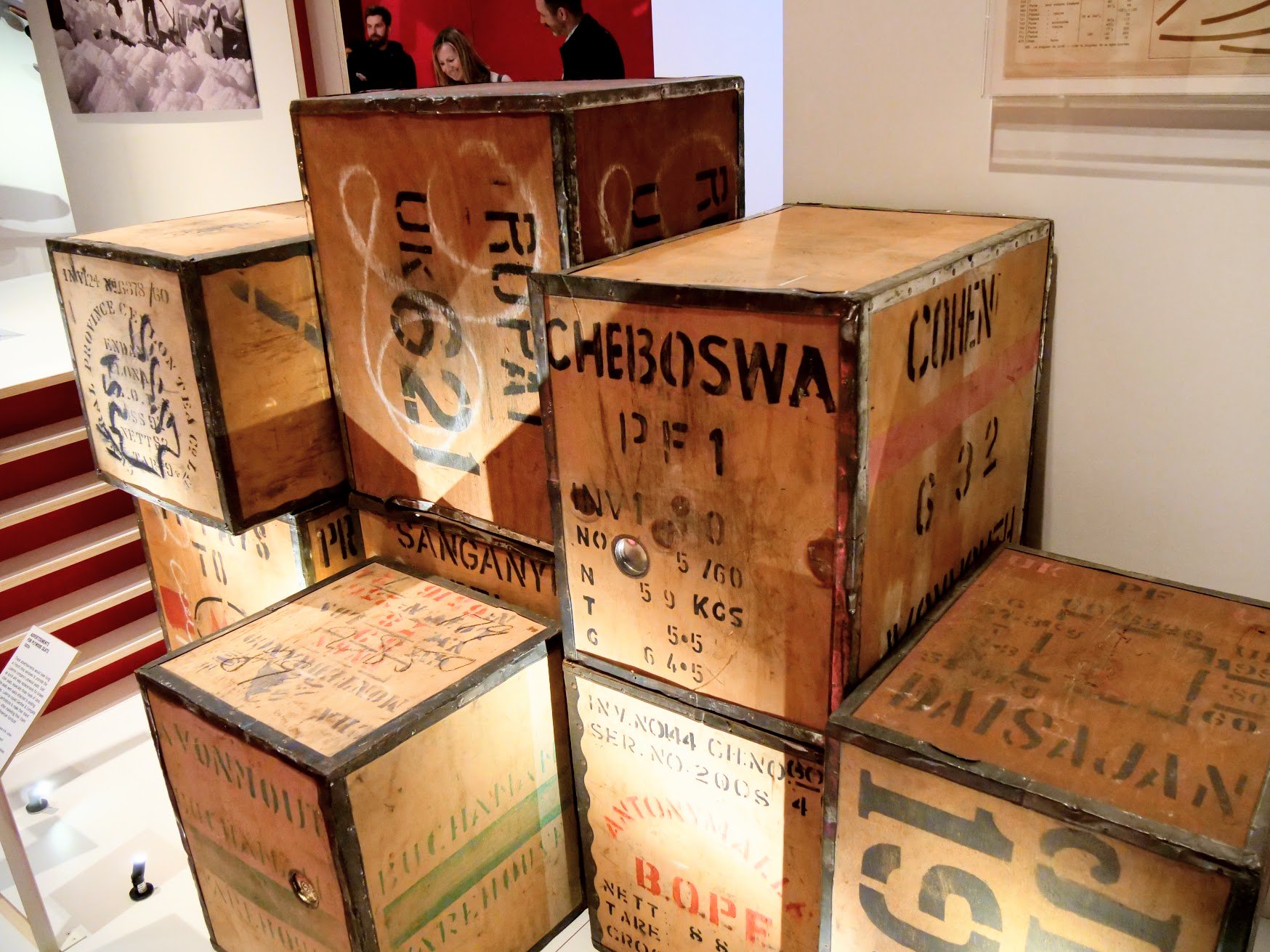

Visiting the V&A (Victoria and Albert) museum and seeing their presentation of Plywood: Material of the Modern World was worth visiting simply because individually we might never be able to pull so many exhibits together in a few hours.

Most of us involved in woodworking crafts like carpentry, joinery, boat building and furniture making to name a few will be used to its ubiquitous presence in both sheet form and convoluted shapes of every kind. That said, there are many surprises for those searching to understand what plywood contributes to our world whether indeed we are woodworkers or students of design concepts. I am not sure if I found any surprises but that's because ever since my youth and the laminating of thin sheets in the pre bag and vacuum-press days of lamination I have always found plywood such fascinating stuff. For anyone with little experience of plywood but interested in materials and the study of the use of wood a visit is really a must. The presentation is very well worth the experience and I must thank the V&A for their being so central a venue for this exhibition.

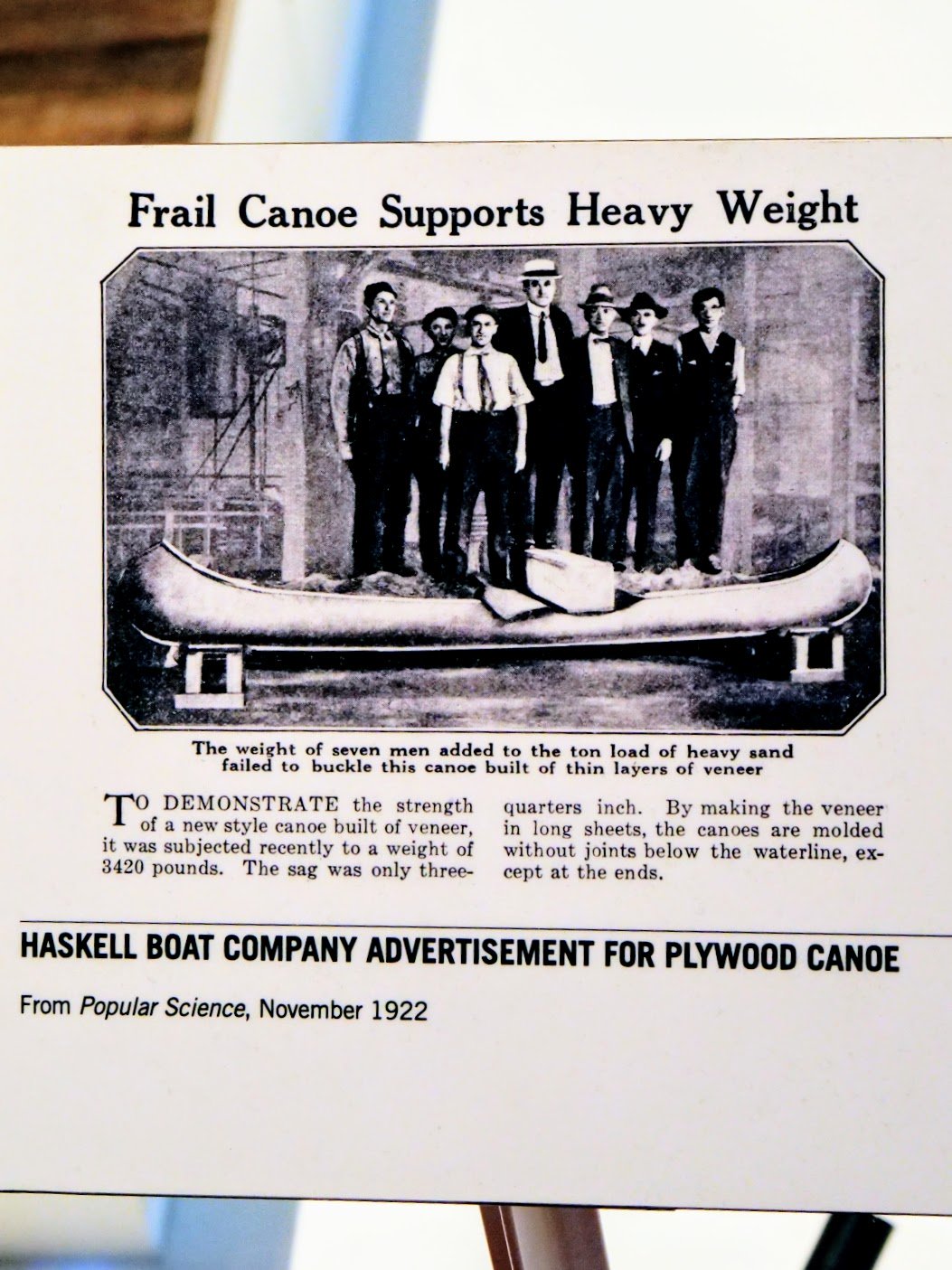

Hollow vessels from thin wood, carved out wood and then birch bark alone span the centuries. In times past the development of fibreglass and resin didn't exist yet still vessels found their way through, loaded with pioneers on most continents. A canoe hang next to planes and boats that took on new developments both through and since the second World War.

Our trip was twofold. Hannah came with me too and it enabled us to approach the world of plywood and discuss a material and its relevance to us. Although plying wood and alternating striations in thin layers may open doors into all manner of shapes and sizes, the ultimate predominant presence of plywood in our present world is in the mass making of manufactured goods via assembly lines. Plywood prefaces pressed fibreboard, wafer boards like OSB and then MDF as so called sheet goods or engineered wood. Skin any of these with a veneer of thin wood or plastic and the sheets cab be stacked and racked and packed to create the plethora of choice we in the western world place high demand for. Of all the engineered boards made, plywood remains the very strongest and the most resilient for long term use. Hence boats now formed from flat pack kits are the modern way for forming many types of vessels ranging from canoes to yachts.

I think we both found the furniture choices interesting in that once more we see the quest of many designers through the decades was and is to come up with designs that can result in their being ultimately mass made through an economic use of motion and time. Predictably the outcome looks exactly as you might expect.

This design methodology seems to be the product of many colleges worldwide and I wonder all the more if that isn't because ultimately success is seen in developing a design that can be mass made to make millions, be that quantity in product parts or in dollars.

Comments ()