Picking Out Wood

Picking out the wood for a project always brings with it surprises. How often do we woodworkers mention to people that we are woodworkers and hear the exclamation, "Oh, I love wood!" My own take on this has changed through the years in that at one time it would have been wood that they loved because wood it would have been. Today that's all changed in that it has become more difficult to know whether wood is actually wood or a man-made alternative. I recall being fooled myself by cleverly faked furniture only to find its chief core to be MDF.

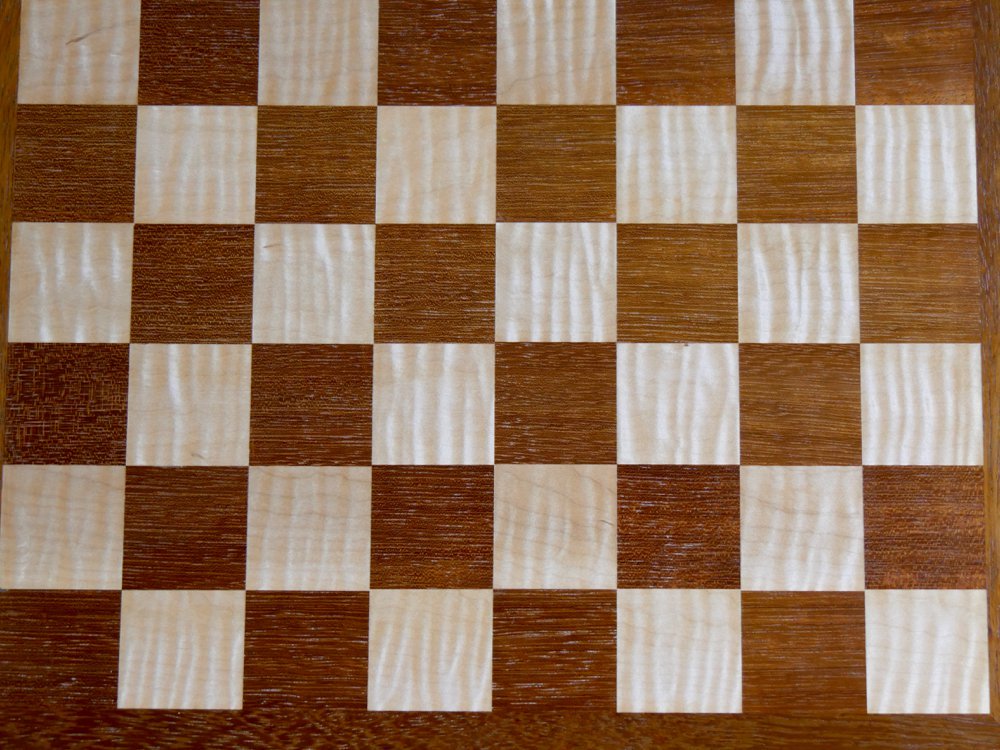

Ripple sycamore throughout this door I'm making

Though I do like that people love wood, most people actually only catch a snapshot of what wood might even be. I say that because to fully know what it is you love is a much deeper and more intimate issue. Looking at a table top or cabinet door with raised panels cannot give much insight to what's inside. Even machinist woodworkers enter this consideration from a more shallow level.

Ripple sycamore rail

When I cut dovetails by hand, chop my mortises with chisels and a mallet, I negotiate fibres very differently. Using a machine you are limited to one way and that is the rotary cut of cutter or cutter head of some kind. When you start to get used to working with hand tools it's surprising how much the dynamic changes from machining wood only. Suddenly you are surprised by its well-hidden depths of character you will just not see with machining operations. Using hand tools becomes more and interpretive negotiation twixt wood fibre, hand and mind. With your hands it is as if a discussion begins taking place and your interpretive translation by skills requires give and take compromise until your intent results in the reality of a a well-crafted piece of workmanship.

Curly maple above in my chess board project. Compare to ripple sycamore top image.

This week, my working with sycamore and maple made me think more deeply about the characters of the different species and why apparently there may often be confusion as to the differences in the species and then within the actual same species too. Sometimes it is most subtle and at other times it is radical shifts.

Three configurations of quarter-sawn sycamore

This image shows three results of quarter-sawn sycamore. Colour, grain configuration and indeed other elements make you wonder if you are not looking at beech or lacewood, plane and some other such tree species.

Now I have had figured maple with striping that looks as absolutely identical to some of the rippled sycamore I am working with here as it could possibly be. You know, whiteness, creaminess, ripple and such. Now, because they look the same does not mean that they at all work the same. There are textural differences perceived only when I feel those contrasts when working with my hand tools that I cannot detect doing the same work by machines such as mortise machines, planers, tablesaws and mortisers or tenoners. So it's this experiential knowledge that then redefines the considerations. We feel inner workings through the chisel tip and plane edge that tell us about the grain in terms of texture, density, hardness, and then resistance, interlock, elasticity, tenacity and so much more.

Bottom two sycamore and the top one maple but the middle one could easily be curly maple and the bottom sycamore piece might easily be determined as beech.

Whereas these three sections are really quite different by appearance they are also different texturally. This image is maple top, sycamore middle and quarter-sawn sycamore bottom.

My door here is all ripple sycamore.

So you see, the benefit of handwork gives you an in depth knowledge leading to understanding woods. When someone says I love wood, I am always glad that they feel that way, but when you work its substance, discover its idiosyncrasies, penetrate its inmost fibres, that's when you discover a much deeper love for it.

Making my cabinet in rippled sycamore could be compared to making violins and cellos made from curly sycamore and curly maple on the back plates and bouts of the instruments. Both work well and impact the sound quality markedly. These figured woods also add greater resistance to cracking because the interlocking grain is stronger too.

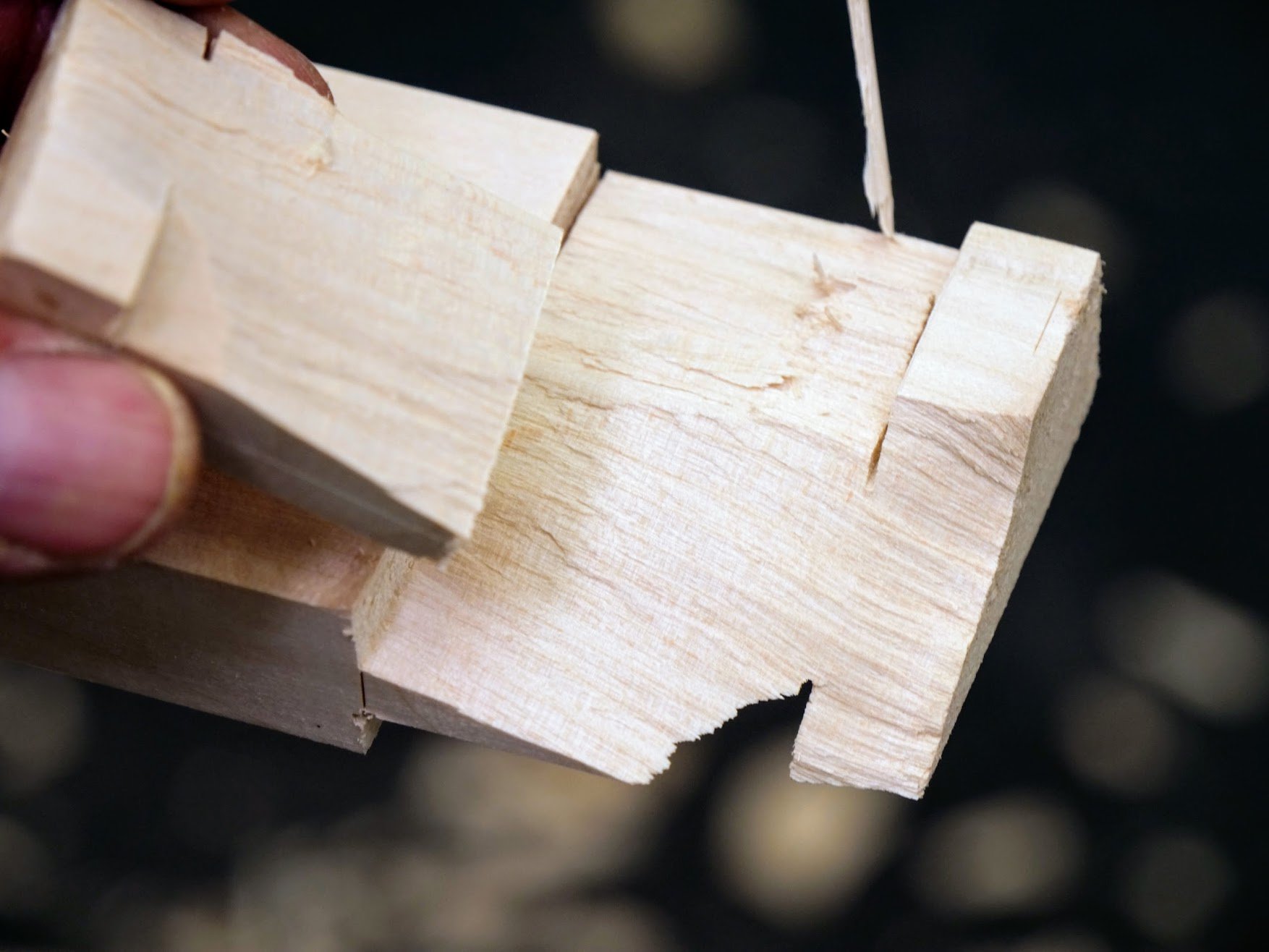

Not always do things go according to plan.

I was not hard on this piece of wood, I did not hit it hard and used only hand pressures, not mallet blows. Both maple and sycamore have many qualities that are indeed closely similar or even identical. Whereas the science might [rove other differences, from a craftsman's view the two woods could be said to be no different.

Comments ()