Disseminating Those Anonymous English Master Makers

Two doors bereft of the cupboard they once belonged to lay askew on a burn pile. Disposal takes many forms for many reasons, but one man's discard often thrives in another's. Whereas some can't be bothered, others don't know the value or whether indeed anyone might want the discard. Time too might be the issue and of course so too storage space. The doors lay there for three days and my original thought that they would possibly get recycled diminished sufficiently for me to make my inevitable move. I U-turned, loaded and took away my prizes. The abandoned work of another meant reclamation for me because I wanted to know the unknown master-maker. It is possible that Britain might well be one of the only cultures that might do such things these days, I don't know, but I do see such things often enough to suspect that to be the case. There they were anyway, outdated, outmoded, unwanted, uncared about and, well, 'brown'. Brown furniture is the modern name these days here in Britain. It's not particularly new, just adopted. Of course it is disparaging. I mean, 'brown'. What? I can't imagine a more derisive term given to mahogany and oak, walnut and others. Even describing it as brown suggests to you a 'just get rid of it' attitude to most, but what’s funny to me is a new generation thinks it’s so, well, smart, clever, upbeat, superior in class and intellect. On the one hand it is all about recycle, upcycle save this and that but then to dis classic, well-made, lifetime furniture as 'brown' seems to me unfeelingly blind.

I did ask myself why? Why would a whole generation do that? It, 'the generation'—I'll be as vague as 'brown'—then takes “ugly brown furniture”, slaps and slops on (literally) some Annie Sloan chalk paint to replicate multiple levels, sands through it, adds wax and renames it 'shabby chic' when of course it is for the main part shabby unchic and more possibly shoddy unchic too. The sadness really is not so much only the trashing of the work and the workmanship contemptuously but the trashing of the 'who' and the 'what' that created it. The integrity of craftsmen they never knew and could never understand, that hand-cut joinery they never even knew existed, the techniques and methods of work that lay silently unfathomed in fibres they will never know of nor understand.

So, yet again, I needed the wood and could well use the discarded and free resource offered on the wasting heap. The wardrobe they came from was too massive, certainly for almost any UK house. At seven feet tall, four and a half wide in one-piece and panels two feet deep dovetailed on the corners could never translate into the world of the 'upwardly mobile', but more awkwardly immobile for all the UK stairways of today's homes. But smart Alecks still thrive in every culture. They are alive and still kicking out but by different names. By the time I’d retrieved the wood I was a few hundreds pounds better off, of course, but it was more than the treasured wood that I looked to gain from, I once again gained insights to workmanship patterns long gone, patterns we generally no longer see or use. Whereas when a machine cuts a good joint it's quite pleasing to see, when the cuts come from hand work only it becomes truly impressive. More important than anything for me was the discovery you see. Here I am learning a few more techniques from a long gone master. His saw and chisel cuts, plane marks and shavings all speak volumes of someone who lived integrity. A man who's life defied anything but accuracy, sharpness and well-proven technology.

Here I go.

I got some top-notch mahogany, clear, beautiful pine and then some quarter-sawn ash. But then I got insights into the joinery and the tools used and then a good two hour's entertainment from the dismantling and disseminating alone. In some countries I know of this wood would never have been discarded or 'found' on any burn pile. It would have been treasured for a guitar back or a keepsake box as the wood is indeed prime quality wood. I now have beautiful mahogany in rich, high;y figured panels 18’’ wide and 6'6’’ long. Who knows what they will make. I think of many things large and small. The sizes of the door stiles are ⅞’’ x 3 1/2’’ after trimming. I just made a stepladder from similar sized pieces. I’m thinking an arts & crafts floor lamp here. Maybe Greene and Greene rather than Annie Sloan.

But I wondered about the joints.

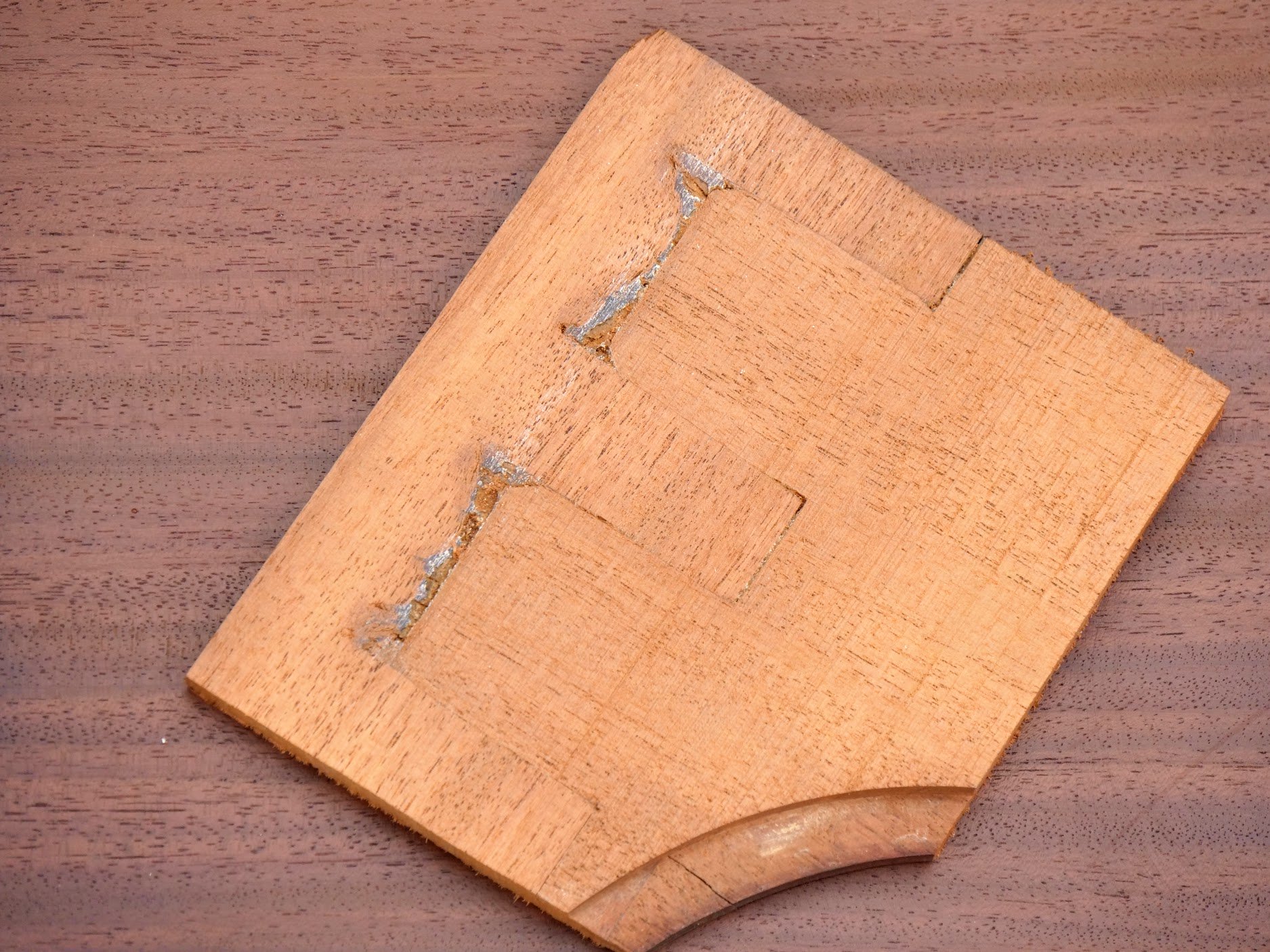

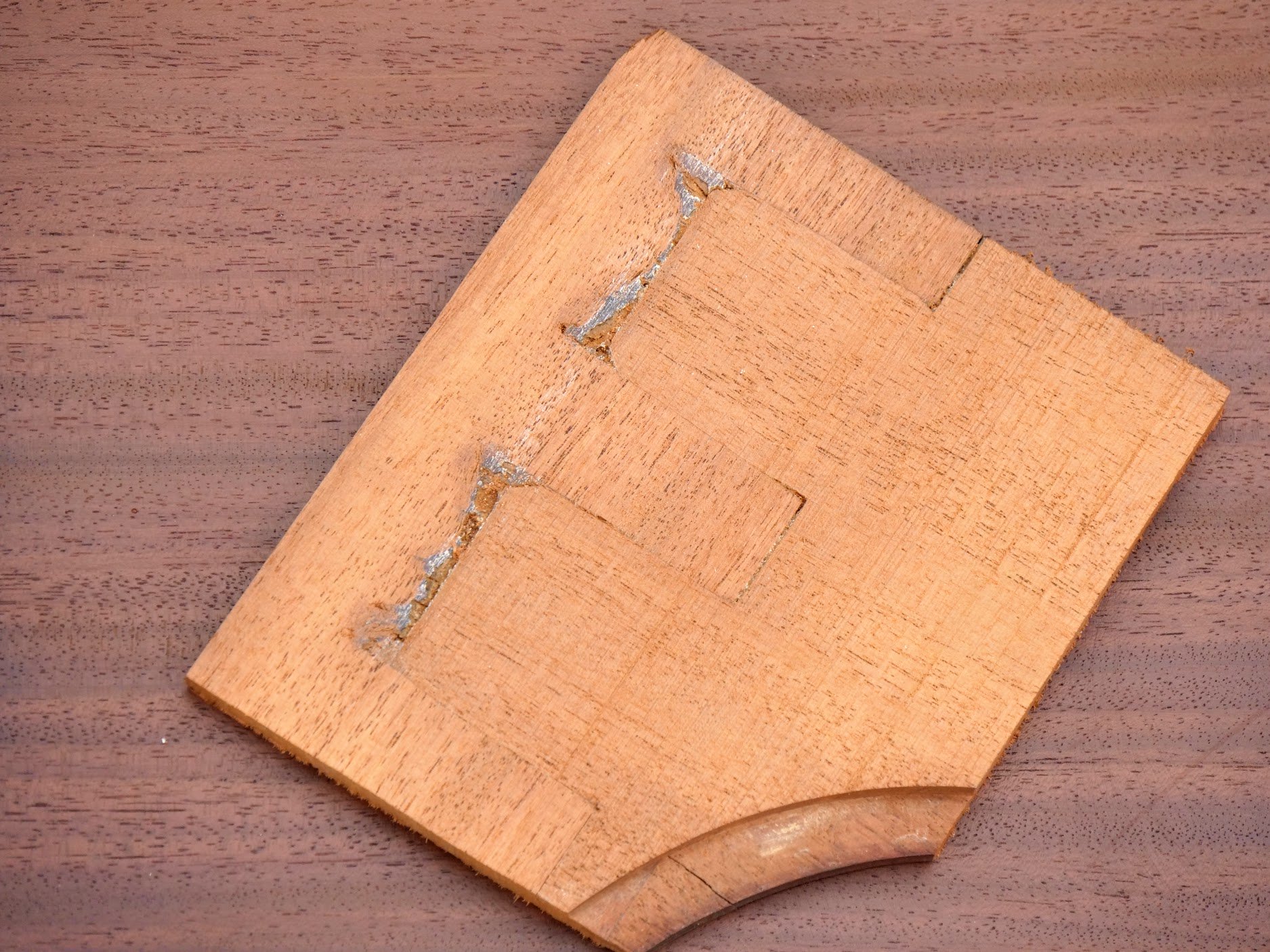

Ultimately I retrieved a pair of mahogany doors (top pic), the main carcass of clear white pine, which had free-cut dovetails and sliding dovetail shelving and then a four-foot wide drawer 10" tall by 22" deep made mostly from ash with a veneered pine drawer front I'm unsure what to do with just yet. They would not volunteer separation even with good heavy hammer blows—remarkably! I cut through the tenons to the top and bottom rails to examine the joints that held the doors together for 150 years or more.

This alone I found quite stunning. Two different types of M&T held the junctures tight, but that was not what surprised me. Look above. Look at the tightness of tenons to the extremes of the mortise holes. Look at the tightness in the widths of the double tenons. Imagine, absolutely no shrinkage. This wood was bone dry when the piece was made. I thought this was lovely work. I split off this section to see the bottom of the mortise.

The man used strong, direct, dominant blows, confident work, no fuss at all. Seven strikes across 3" of width. Well different to some of the prissy, tap, tap, tappy taps I often see and hear more of these days. See how amber the hide glue shines so in glossy glass-hardness. Hidden for over a hundred and fifty years but now unlocked for me to glean from. The chisel was a heavy mortise chisel. I know this because of the strength of the chops and the distance they are apart and then because of the depth they were cut to, 3". See too the chamfered corners to the tenon ends inside the mortise where I split it off. See too the glisten to it that shows the sharpness of the chisel. Every time, without fail! I personally think this to be a marvellous thing. He took his inch wide chisel, a firmer, and pared off the corners as I do with my bevel edged ones. I can see it now, him putting down his tenon saw, paring the face of the tenon to fit and then in a single stroke, removing that corner without thought or hesitation. I can hear the mallet blows on a block now as I write. Four blows to fully seated shoulders. No fuss, no prissiness. Nothing affected, no aching, no headgear, no dust masks needed, just raw work, raw energy yet nothing crude at all about it. This man was a master. An unknown, anonymous man, powerful, independent, strong and reliable. He was an accurate man, intense, fiercely determined in his work ethic. Moderate, dependable. What else can I say. I think he was an admirable British workman.

So why the two tenons?

This was to do with integrity—the integrity of retaining fibre in the stile to keep the outside faces of the mortise tied to the opposite sides. He enclosed the tenons on five sides and sealed them with airtight shoulder lines—no undercutting anywhere. Lovely work. Just lovely!

The choice for two tenons at this juncture was due to the wider top rail. It needed either a wide tenon to constrain the full width of the tail as much as possible(that's the lower part to the arching, or the two in tandem as shown. I noticed too how the mortise deepens to the inside corners of each pocket. This is quite common. The bottom of the hole should not touch the end of the tenon sufficient to hinder seating the joint at the shoulder. Now see how square the ends of the mortises are. How parallel. I mean we are talking totally hand cut here and dead on squareness too. There’s more.

See the twin arches? These have a slitter of mahogany extensions cross plying to catch the thin extremes of the arch adjacent to the stiles. The slitter 3mm passes through the arch and then enters the stile also - I imagine 3mm inlaid this way. More less obvious integrity! Solid, dependable. When I first looked at the whole door I wondered about so thin a point. Yes, it was split, but it seemed to be holding its place. Had it broken and been reglued, all six of them? Nope! There it was. A thin telltale of opposing grain ply but not plywood. Lovely, precise cutting. Now for obvious reasons the middle element of the arch had no added reinforcement. This part shrinks and expands unhindered.

Here’s a question

I actually don’t know of a single professional woodworker that cuts mortises by hand as standard practice. Everyone I know as a professional is for the main part a machinist. I haven’t known more than a handful since my apprenticeship in the 1960’s. Those in the handful are mostly ones I worked with and trained at some level or other as an apprenticed. That being so, here’s the questions. Have you ever seen mortise and tenons with end cuts, that's the sides of the mortise holes not the tenon ends, as well fitted and square as those shown in this article? This is very remarkable work. Just remarkable. It teaches me yet again about exactitude, self discipline and much more. So I lift up this unknown craftsman who’s work shames our modern-day progress that gave us boring assembly-line production methods even in our weekend working. I hope I for one can learn that it’s not near over yet. These tenons fit tight in thickness too. Not an ounce of wiggle room.

No wiggle room and no room ever for air and perfectly sandwiched equidistant between the mortise checks. A mortise machine? Nope, none in sight in this man’s world. So with verniers I determined the walls were perfectly parallel, equal in thickness of mortise walls and tenon checks.

Now I admit the drawer dovetails to the rear of the drawer below were not as perfect as the door joinery. I suspect the apprentice was involved here on the back through dovetails. It was common practice to put them on the rear ones as they were rarely ever seen. Here you see a pine back and ash sides. Not so common but not rare either.

I don’t know but with the M&T being as perfect as they were, and the drawer being just a tad more tolerant of space between, that was my thinking. But then I thought perhaps not. Ash and pine seemed an odd combination for such a massive and deep drawer. Perhaps differences in expansion and contraction was to do with it. Also, often, interior, unseen work was given to lesser men. Maybe the journeyman. Now that’s it, apprentice or journeyman. Let's blame them!

Comments ()