HVLP for spraying shellac and other finishes

Contactless finishing

I generally pick my weapons of attack to match the work battles I encounter so I have learned a few things about finishing through the years. There is no doubt that giving a good finish is critical in an age when furniture makers must no only make but finish too. Just about the time when I had finished my apprenticeship in the 1960s, wood finishing by the masters was coming to a close too. I soon learned that if I couldn't finish my own pieces, I would soon be out of work.

As a furniture maker I have sprayed different finishes on some production lines starting out in the 1970s when everyone used the conventional cup gun hooked up to any standard air compressor. If you’ve ever sprayed sticks and spindles you’ll know that 90% of the spray goes past the thin sections and out into the biosphere . In those 'olden' days, as one of my children once said, it was high air pressure from the compressor and high volumes of the finish you were spraying with. The finish was fine, excellent in fact, but the atmosphere was filled with much more wasting product than should have ever been allowed; bad for health and bad for the environment. We were ignorant back then but we did make progress via a remarkable new piece of kit and change came. A new spray rig powered by a turbine came into being that gave us the high volume we needed using much lower pressure, infinite controllability and freedom from the swirling winds created by the air compressor. Suddenly we were able to put finish exactly where we wanted it in exactly the right proportion. HVLP sprayers were easy to work with and could be adjusted to all but a pin prick in diameter. The were here to stay and the outcome has proven ideal for coating all kinds of pieces with just about any kind of finish, so for water-borne finishes, oil finishes, dyes, stains and water-based paints and also shellac I was a very happy worker of wood.

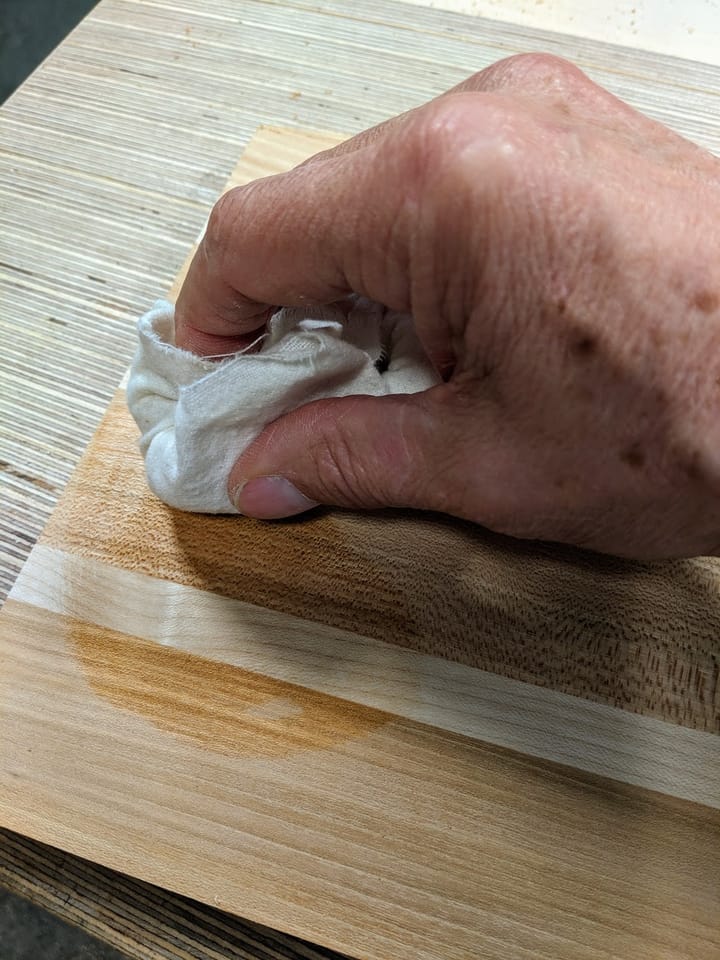

The importance of spray finishing is basically twofold. It’s fast and, with skill and knowledge, it gives a perfectly even coat in exactly the right measure right where you want it. This translates into good economy of time and money. Because it is brushless, a skilled sprayer can place the finish on in multiple layers and leave a near glass-like finish that often results in a completed work. These gates were sprayed and three coats to a full finish takes only a few minutes per coat. With minor sanding and almost no rub down subsequent to after the first coat, any hand contact is kept to a minimum too. This is because the grain is not agitated by any brush or contact applicator. The thinned first coat dries and is rubbed down with fine abrasive. Subsequent coats are sealed away by the first coat. Simple.

Imagine brushing on such a finish and how many hours work that would take.

I sprayed this guitar with a water-borne finish ten years ago. I used a quite pricey Apollo HVLP sprayer I owned back then. Because I don’t make too many pieces to sell nowadays I tend not to spray for speed so much but more for the ease spraying gives. I usually brush or wipe on finishes on smaller pieces and that’s what I mostly do if it's a one off small piece. It's quiet and easy and I am used to hand applications. If I had 10 tabletops to do, on the other hand, I would most likely spray.

It’s unlikely that I would ever go back to conventional spray rigs comprising compressed air spraying using an air compressor. HVLPs rely on a compact (but noisy) turbine to push air through the cup gun and it’s this that gives the infinite control of volume with low pressure. The low pressure capably lifts the finish from the cup gun to and through the nozzle with surprisingly little pressure and absolute volume control. This reduced pressure disturbs the surrounding air hardly at all so the atmosphere remains for the main part quite calm. A desk and projects like these below can be completed in a matter of just minutes.

Shellac should be sprayed in a warm atmosphere and each coat takes only a few minutes to dry. In an hour a piece can be ready for delivery. I use an Earlex 5500 HVLP sprayer. It’s one of the least expensive but for my level of production it works perfectly. There is no piece of furniture I couldn't spray with it. When a turbine is going for long periods it is important to have a turbine designed for high volume production.

Comments ()