Dealing With the Flakes in Woodworking

So you dinged a corner or some wood flaked off. If it’s cherry flake is quite common, in maple much less so and oak it can be ultra common for such things because of the medullary rays. It happened on my current cherry dresser-build when I didn’t need it. Not quite during filming but near to. But it is a commonplace enough issue when you’re working full time on woodworking and furniture making and you can’t throw half a day’s work and £50 worth of wood away, can you?

Fixing flaws is of course a part of what we do. Dings will of course come out with a hot iron and a damp cloth in a heartbeat and it works almost every time. Flakes can be a little more problematic as no amount of ironing will put would where it wasn’t before. People often ask me when `i am working on a project why I keep all the waste pieces accumulating in a pile on the corner of my workbench somewhere. The reason is flakey unpredictable wood or unpredictable things happening to wood when you just don’t need it. Here I am about to film and a flake seems to have occurred without me knowing. Could I find the flake? Well, I suppose that’s the thing about flakes (whether that’s people or wood), they are just not to be found when you need them the most. Though I had yet to sweep the floor, this flake was well and truly gone.

Rooting through the pile of bitty offcuts I found a piece with the right colour of grain and grain orientation. I planed out the angled flake till dead flat and then lined up the grain to glue a replacement grain section in place. Leave it as a fairly substantive block and don’t try cutting it down to thin. The blockiness and size aids clamping. Once it’s glued and set you can pencil in cut lines with a straight edge following the corners as I am doing here and the block being so anchored is easier to cut and plane level.

Cut proud with a tenon saw and away slightly from the surrounding surface. Not rocket science; much more complex. Did I tell you I have had rocket scientists from NASA fairly frequently in past classes. They wanted a career change when they retired. It was one of these that introduced me to my first digital camera and back then I paid $1200 for 1GB compact disc card for it. Most cell phones do more than the camera did. But it all started me writing curriculum and a fine dentist called Dr Bill Hendrickson from Wichita Falls, Texas who was in one of my classes at the time together with his wife Suzy, took pity on me and bought me the first digital camera I ever owned. Anyway, on with the flake here.

With the new replacement flake unflaked and cut to rough place, take a #4 and plane flush. Do the same to the other two edges and sand as needed.

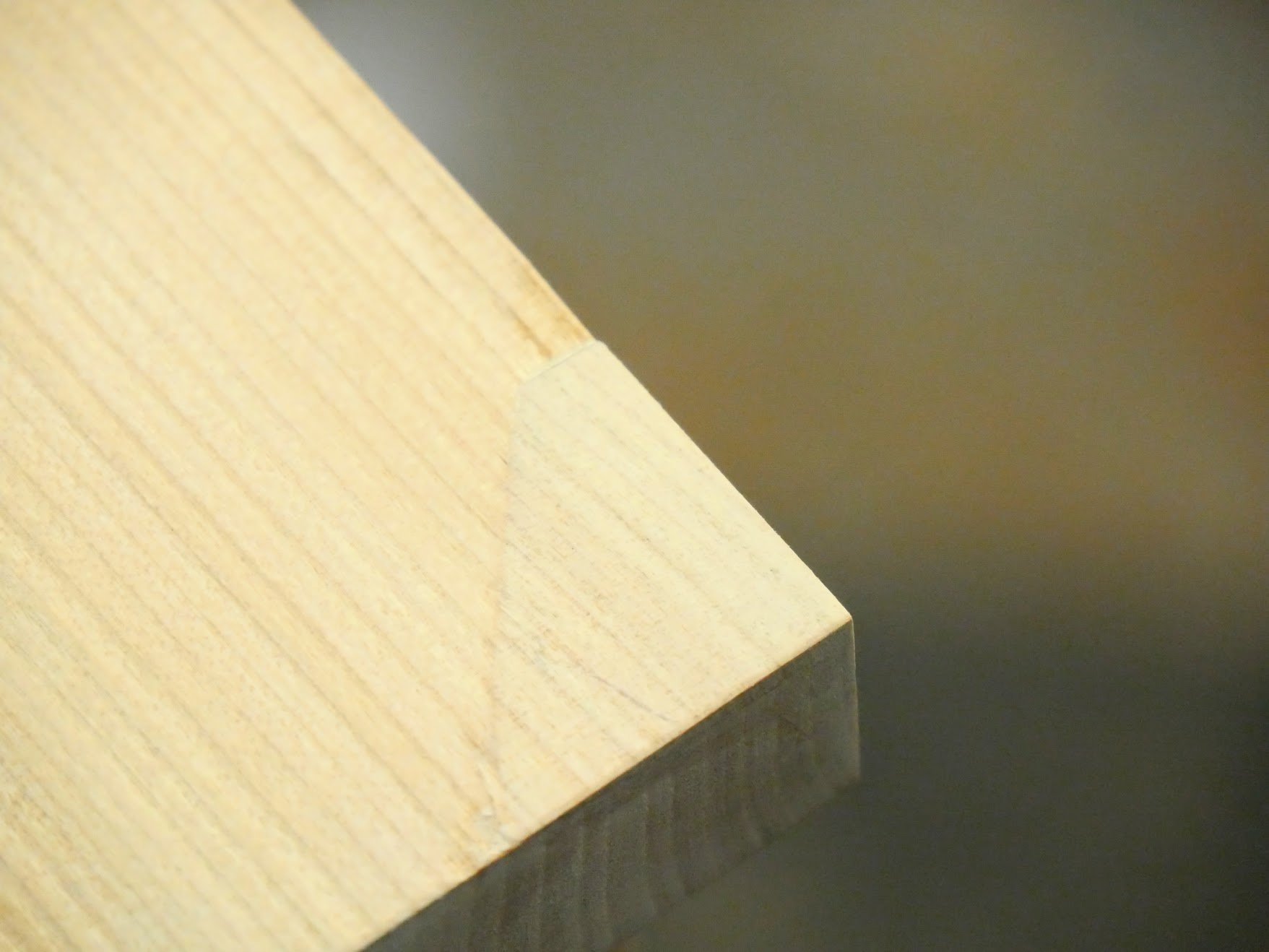

Here’s where we ended up.

Comments ()