Identifying the Need—You Answer the Questions

I think it is important starting out that you identify some key elements that help simplify your development. Here is the first of a few things I have worked out through the years.

Identifying the type of woodworking you want

I suppose I'm a general allrounder when it comes to woodworking. That means that I would understand building a timberframed home or barn without much of any research and I would have no hesitation in making a guitar or a violin. Boats, canoes and of course furniture of most if not any type would pose no real issues of concern to me these days. I've sold wooden boxes for $5,000 alongside rocking chairs at $7,000. My work is in the Cabinet Room of the White House and so too I have 3 of my designs in the home of at least one president and six more grace the homes of two senators, if indeed all of that matters. The first important consideration if you follow this blog, my YouTube and other online facilitators, you will see that my main focus is educating hand tool woodworkers of every skill level. 25 years ago, starting my new life then in the USA, I didn't meet skilled hand tool users. They were there,of course, but they were very few and far between. Anyone that worked with their hands might well be considered some kind of eccentric or a hippy or a rebel of some kind. Whereas at that time, in the USA especially, woodworking began its great emergence as a mostly machine pastime and low-cost machines seemed to ever-flood the market. Whereas I was used to powerful machinery, I used mostly hand tools for my work once the wood was machined to the dimensioned sizes I needed. To me this was the perfect partnership. Machines for more laboursome work we called the donkey work and then hand tools for the versatility they bring to really fine-end woodworking. I am glad that people following our work are achieving higher levels of workmanship. Workmanship they can be proud of. It seems to me now that the people following us have much higher confidence levels because of their hand training. They enter into dialogue on forums and express a confidence they can speak out in defence of. This decision to move in this direction is important. If you do choose this, you will never regret it.

Of course I use machines

Just not much of the time. Of course you will know that I rarely show machine working in my work, not yet anyway. And that's not because I never use them, or in any way deplore them. It's just that that has become old hat for most and people are not asking for that from me. Of course people now know that machines are less the essential that they first thought they might be and I think our work has indeed balanced out was felt throughout those decades to be the answer. Because I do have developed skill and working knowledge, using hand tool woodworking methods often work more efficiently for the work I do. This is actually true for anyone making anything from wood. The problem is most people give up too early, have over expectations or develop machine methods that are, well, close enough for them. Unfortunately this leaves about half to two thirds of the population squarely outside the woodshop door.

Machining wood by amateurs

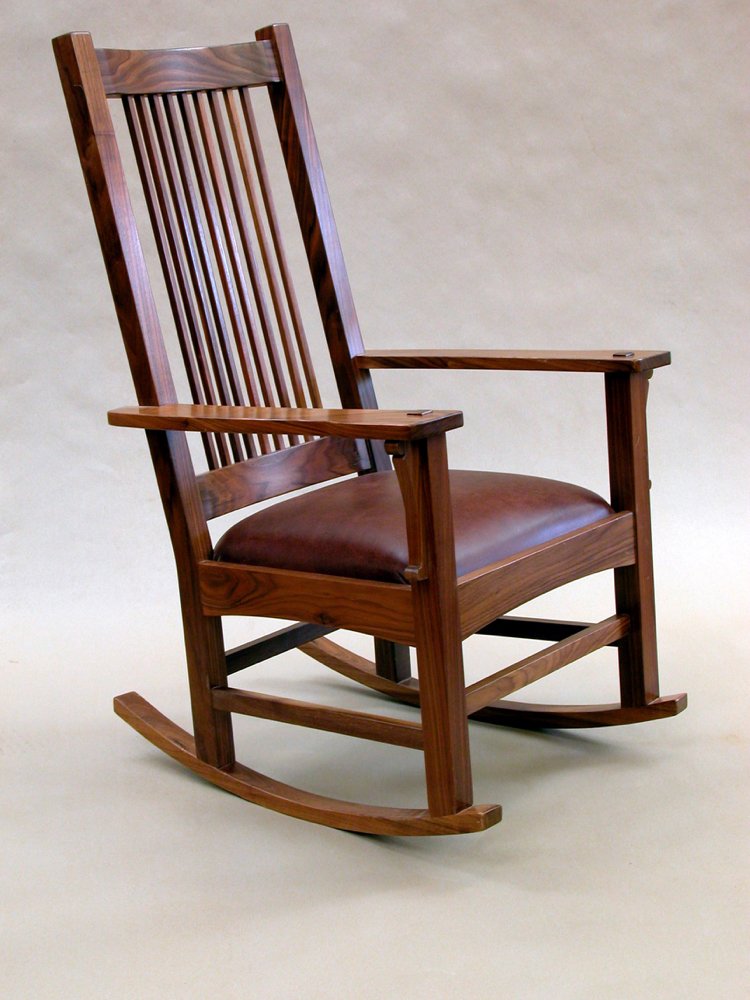

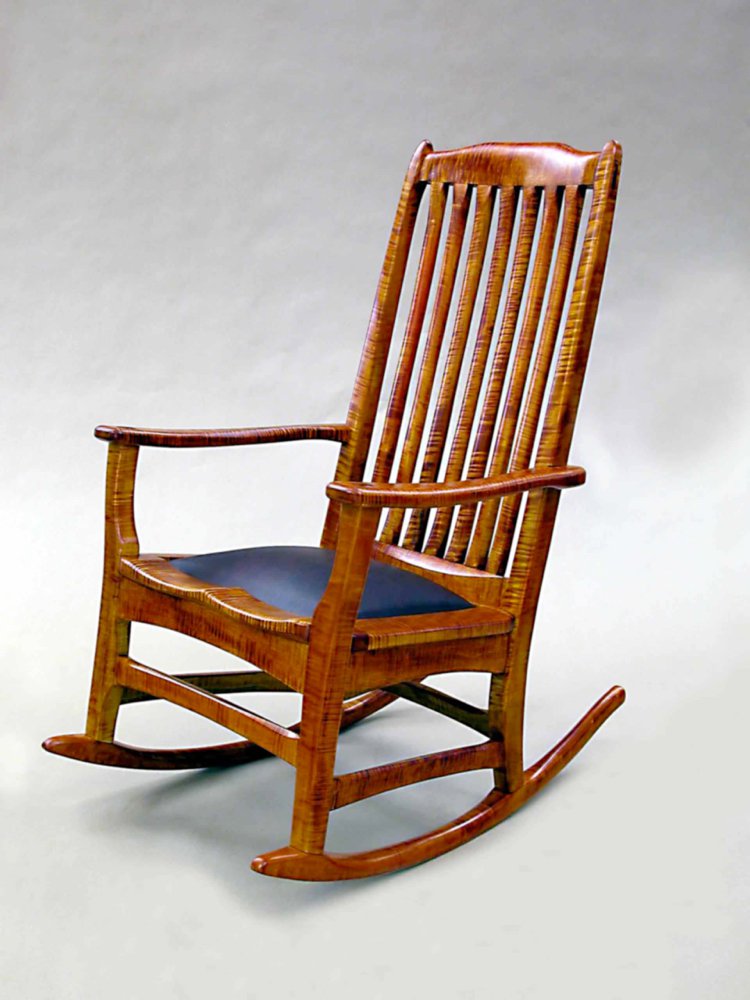

When I moved to live and work in the USA I made pieces like this rocking chair and sold the likes regularly for anywhere between $1,700 and $2,000 just at craft shows around Texas and a couple of other states. They take me five days to make completely and utterly by hand. Here is another style that started at $6,500 and went on up. I designed this one around 15 years ago and they sold and sold. So what I want to say is that in most cases experienced machinist woodworkers might only rank as raw beginners when it comes to hand woodworking as these skills cannot be developed by using machines. That being so and machine skills not being transferable as hand tool skills, you will see that machine woodworkers are often only beginners in the hand tool woodworking world. This is my experience. That being fact, machinists generally advise new woodworkers to buy machines first as though this is the necessary entrance into woodworking when it's actually the entrance into machine woodworking only.

Machines are really good for dimensioning wood

If you give thought to today's woodworker you don't get too far before you see that woodworkers want wood machining mostly to dimensioned size and something that eliminates skilled work such as crosscut sawing square ends. That's because to them joinery at intersecting points for frames usually means biscuit joints (not a true joint by definition at all) or pocket hole screws or dowels and screws all of which require square ends. Thus they look for substitute to joints and joinery. But that's not new at all. Most furniture from the late 1800s and early 1900s had dowelled components that replaced hand made joinery for the obvious reason that there was high demand for furniture on a local level but more skilled workmanship became evermore costly. Dowelled joinery, if we can call it joinery, was both strong and fast. It lasted well, for a decade and more, and most doors and framed construction for chairs, doors and so on were simply dowelled together. This minimised the need for skilled men. Today's replacement for that is the ubiquitous biscuit joint. Not technically a joint at all, this substitute has become accepted universally but I can't say I like except perhaps for mass manufacturing work, especially building say kitchen cabinets and such. I am surprised that furniture makers rely so much on them. Creating fine joinery doesn't take much more time than it takes to set up the biscuit joiner and fine joinery is good for any man's reputation.

What do you need to become a woodworker?

The question then becomes this. Have you decided that hand tool woodworking is a necessary path for you? Do you want to master skilled workmanship using hand methods? Are you prepared to invest your time in developing your skills?

What goes around come around

So, here we are. As with fashion, we've come full circle. I think that we have at last turned a corner when you see that men who once only considered buying power equipment are now proactively pursuing hand tool methods that demand real skills and working knowledge too. Though on a much lesser scale, I see many more people, men and women, looking for hand skills that really count. Over the past 20 years I have seen people choose the more radical path and turn steadily less toward the machine only methods of the 80s and 90s. This picture here shows the people who attended my month-long course. They made a coffee table, a dovetailed tool chest with dovetailed drawers and then of course their rocking chairs. Seeing things like this take place has been my greatest reward. This and of course my work with woodworkingmasterclasses.com, my blog, YouTube and so on.

All that you see on this page and indeed the thousands of blog pages I have written reflects only hand work. Is this what you are looking for. After 50 years of working wood by hand and of course a percentage of machine work in a perfectly balanced way, I look back and say that the best thing I ever did was discipline myself with the art of hand work.

Comments ()