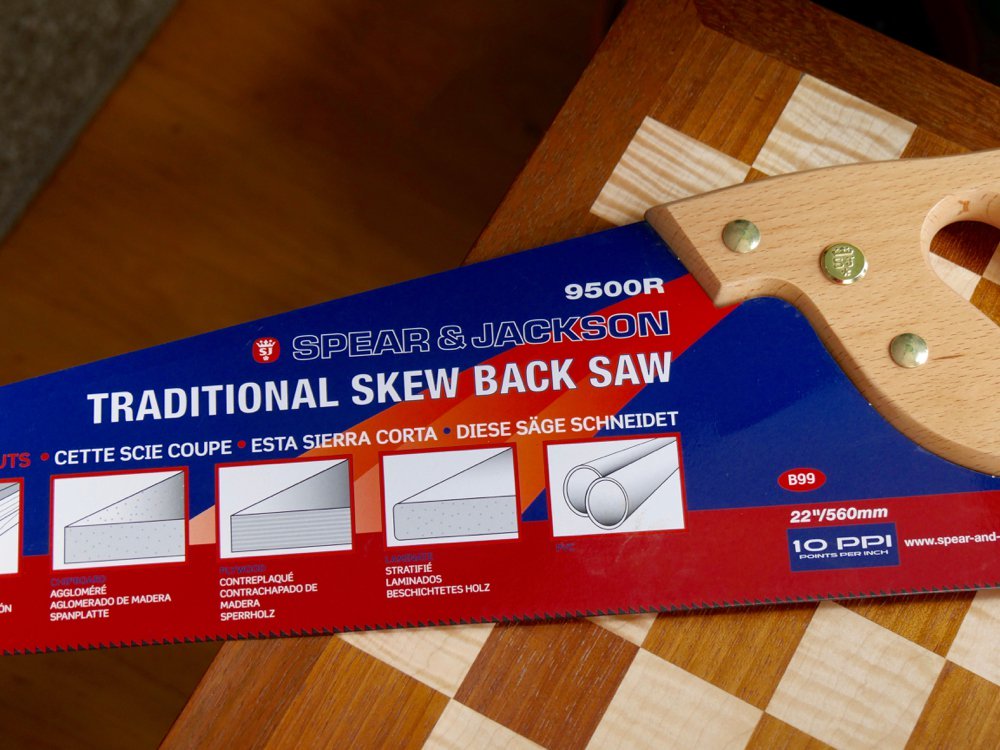

On New 22" 10pt S & J Saw–Great Saw

A couple of months have passed since we mentioned the new Spear & Jackson saws I tested out, refined and upgraded to create dedicated rip and crosscut saws. Someone wrote me recently to ask about the shorter 22" 10pt saw, to get my opinion on it. Fact is, for those of us who want to master sharpening, own saws that can indeed be resharpened and then have a panel saw to boot, The Spear & Jackson really fits the bill for me. I remember about ten years ago when a USA tool catalogue supplier asked me to test out the saw.Back then these S&J saws including their tenon saws were very much kits and that was how I advised purchasers to view them.

I wrote an article for a US mag when I was writing articles and explained the down sides of buying such saws but also suggested not disregarding them as a solid option for buying a new saw as an inexpensive option. That's not really the case today. The last blog article I did a few months back now was well received and of course I am sure S&J thought it was them that made the saw popular and the sudden spike was their strategy when in reality it was of course us. So, here comes another spike in sales even though I may not like their business model much at all. Fact is these saws do make excellent panel saws and are great to use, they are very comfortable and they are indeed lifetime saws. Lets look in a little closer.

As with all companies like S&J they manage to cheapen their own product and the fastenings used to connect the handle to the plate are indeed, well, less than they could be. That said they do work and there is no movement between the handle and the steel plate. If it bothered you you could buy decent ones and replace them.

The handle is surprisingly smooth and comfortable even though the opening is bigger than it need be. Made from solid beech and nicely sprayed with a lacquer finish I still feel it falls short of good looks if good looks is what i want. In this case I wanted a saw I could recommend to anyone starting out without losing any of the emphasis on functionality and longevity. If you did buy this saw you would have no need to upgrade to own a better working saw. This saw is not a stepping stone but one I would be glad to use for the rest of my life.

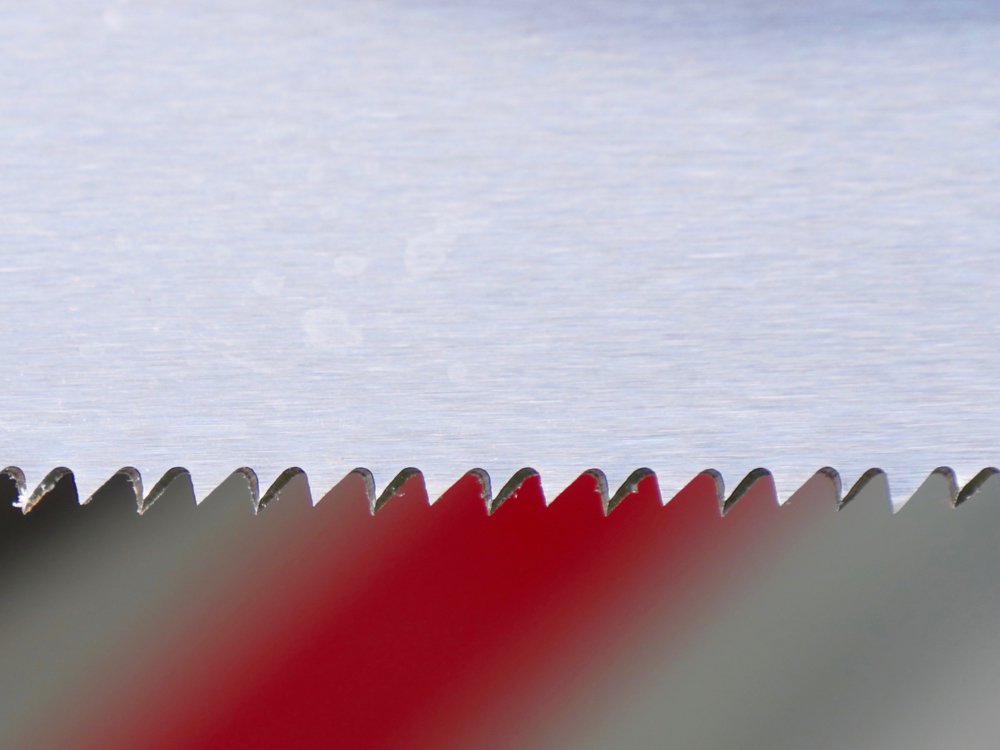

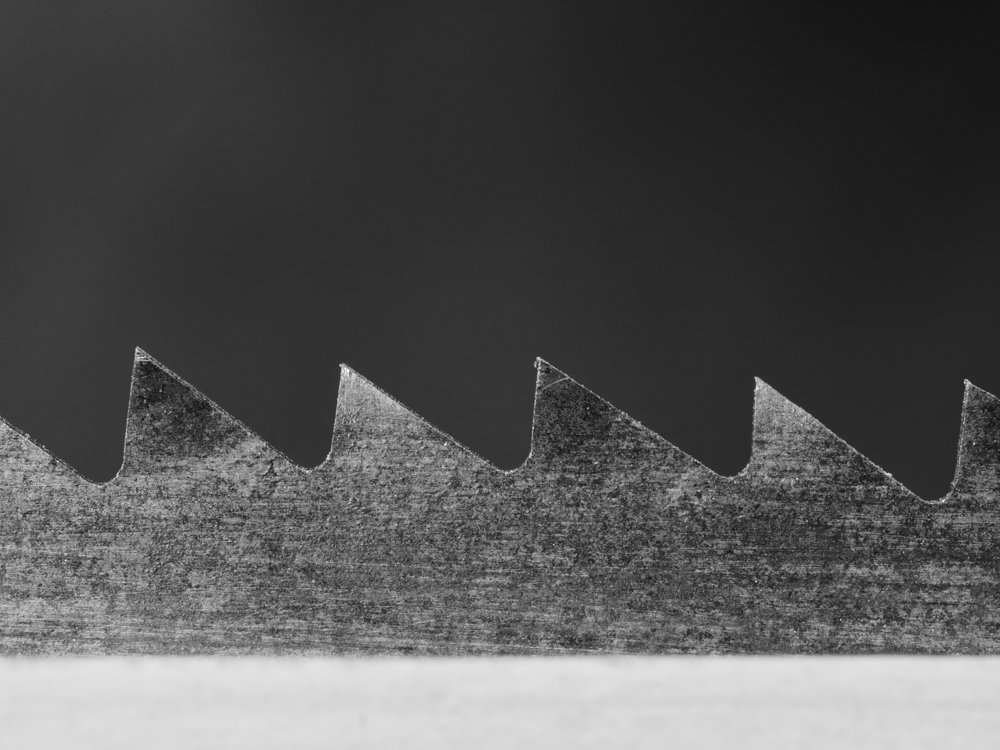

Offering the saw in a ripcut cut the saw cuts fine along the grain. That said, with a minor change as shown above it could be easily and quickly transformed to a dedicated ripcut saw. We walk you through this in our video on YouTube. In my view the saws are inexpensive enough to buy one and keep it as a crosscut and a second one to reshape as a ripcut. I must say that it does cut fine as a ripcut but as a crosscut it's superb. I cut down into 22mm (7/8") thick white oak in ten strokes to get down the distance shown. The cut was extremely smooth and clean and the saw just stroked through the grain easily.

For £22 delivered free the saw is very inexpensive. I tried it on 6mm (1/4") plywood too. The result was a beautiful straight cut with non of the problematic jarring you often get with thin materials like this.

On the sleeve the one-size-fits-all-purposes is disgusting at best. "Plastic pipe", MDF, plastic laminate. Aaargh! Forget that.

Comments ()