Chess Board, Occasional Table and a Matched Pair of Sawhorses

Over the past few weeks we've seen many international shifts and we've been filming projects that are quick and effective to make by hand if you know how to do it. Our audience grows day by day and of course the internet has taken down most of the social, economic and geographic borders once forming barriers to prevent access to our work and our ethos. Three decades ago what we do and take for granted might have been impossible for most. Today, with the help of a very dedicated and caring support crew, we reach between 1.2 to 1.5 million woodworkers in any given month. We have been able to encourage woodworkers worldwide with ways of power woodworking that have no plugs, cables or batteries. People are now realising just how easy it is to gain mastery by doing real woodworking. Furthermore, often, certain aspects are simpler and less invasive using hand tools and that means of course they are more inclusive on a much wider scale. Remember still that a large percentage of the world has no access to electricity let alone woodworking machinery. You'd be amazed at the work I see coming in most days via social media and our websites. Woodworkers worldwide are being empowered by our outreach because most countries can relate to the work we do because of the methods we use. Showing a machine can and does mean an automatic cutoff for many even when they do have electricity. Add into this equation that machine methods must automatically exclude as much as 75% of the average family members and friends in the western world and you start to see why what we do is reaching an ever-increasing audience of people who actually love working with their hands. Of course I have banged on about the reality that children are ostracised from woodworking because the skills have been eschewed by so many. This condition is made all the worse by the neglect of crafts like woodworking and metalworking in state run schools internationally. Kids love woodworking with their hands. That's a reality.

Making the chess board

In this video series I made the components completely by hand and surface planed the final thicknesses from the handsaw with, you guessed it, a #4 plane. It wasn't at all laboursome or hard and I needed no additional healthcare or safety protection or extraction for waste. The sizing for the chequered tablets and the thicknessing was all within extremely tight tolerances and that is minute fractions of a millimetre. The corner splines until now were always done by machine but with this series we have changed that. No routers or power equipment of any kind. Also, don't think it was hard, it was very easy to accomplish and of course can be adapted to many other projects including boxes you might resort to making using jigs and guides for a router or tablesaw. I know it seems quite a way off, but what a perfect Christmas gift for a game player.

Our aim as always is skill building. We're finding steady and ever-increasing growth in our outreach to woodworkers wanting to establish serious hand skills as part of their everyday woodworking. They want their kids in the workshop and want the noise levels lowered in favour of their neighbours. For this chess board piece I used a plough plane, a couple of bevel-edged chisels, a #4 Stanley, a ripcut handsaw, tenon saw, dovetail saw, marking gauge, layout knife, pencil and I think that that is it. Oh, and a #80 scraper and a card scraper too, sorry. The thicknessing of the pieces were made using a process I developed for hand tools that guarantees you can get uniform thicknesses within a thou' too.

Before I went to Israel two weeks ago I filmed the series making one of my favourite furniture making pieces which is an occasional table with tapered legs in the Shaker style. It's not just how to make a small table but how to make tables. This piece is very scaleable and building one sets you up with the knowledge and skills to go on and make your coffee table to match, your dining table too, even. It's real wood remember, real hand work, real hand tools and real woodworking. Remember a few months ago we built the dining chairs as our instructive series on chair making. Last week I was quite shocked when I visited IKEA. It was very entertaining for a couple of hours but I found it a little dispiriting too. It made me realise all the more that the work we do is so well worth it. I found legs for dining tables made from pressed fibreboard and wrapped with a veneer of either plastic or wood veneer. That was bad enough but then there were 5/8" by 1 1/2" door stiles made from pressed fibreboard and wrapped the same way too. It wasn't that I didn't expect pressed fibreboard shelves and doors so much but table legs and door stiles means a five year lifespan max.

You have to read between the lines on this description too.

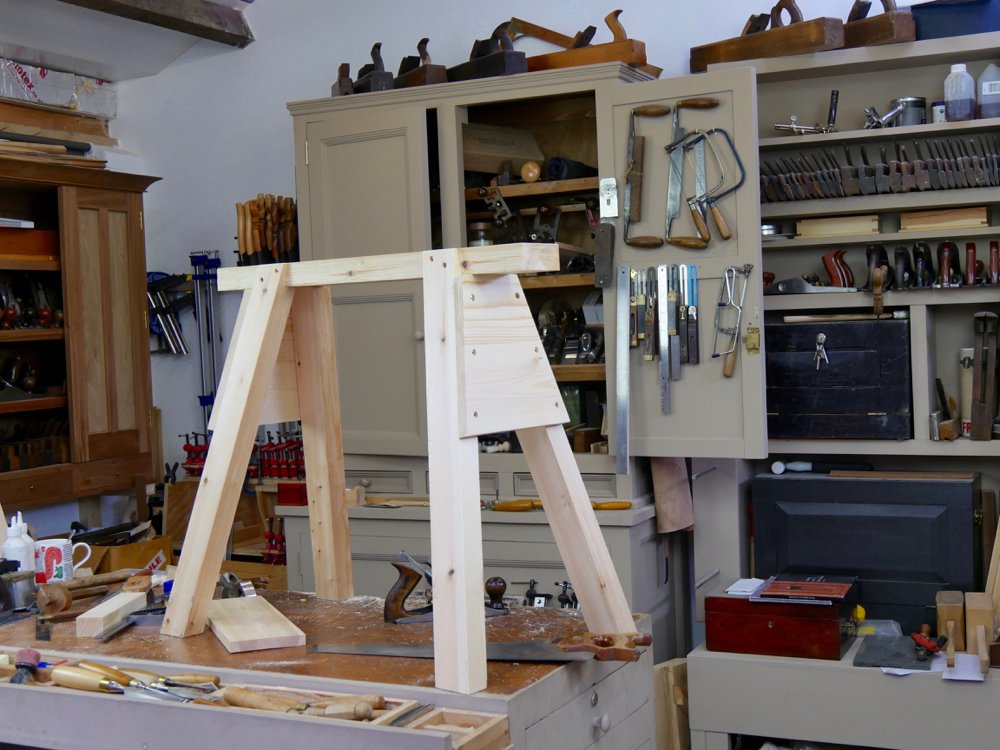

Last week we filmed another series that follows on from the chess board and the table making series. This is another amazing skill-building series too. Every woodworker needs a stout pair of self sitting sawhorses that are stable under different pressures. I blogged on this some years ago but now we have the video series in the bag. Remember that my sawhorses do not splay out only in one direction but but follow the true traditional pattern to go in two and they are fully jointed with compound seat cuts to each leg housing that then undergirds the crossbeam. These methods may well be lost to most woodworkers these days but now this is recorded I can rest knowing it will always be available for generations to come. These are lifetime sawhorses and contrary to popular belief they do indeed stack nicely. You can make them from three two by fours and some offcuts of one-by or even plywood for the gussets. Today I made a followup video without breaks making my sawhorse in an hour and a half. I can make two in just two hours so we will let you see that once its ready for broadcast.

The three legged milking stool is one we also filmed for YouTube. Forgot to mention that.

So much work, so little time!

You might want to consider using the chess board as a tabletop for the occasional table and use it as a gaming table instead.

By now you will see that we are into real. Join the thousands who support our work to make woodworking real around the world. You can subscribe to woodworkingmasterclasses.com for free or become a paying member and receive weekly videos on the projects above and indeed hundreds of past videos too. We have quite an archive of superb content. Go here for details and thanks for reading the update.

Comments ()