On Vises—Part II

Cutting the vise opening into the apron and fitting the vise

You can, as I said, use a jigsaw, but the hand tool method is more fun, more demanding and of course you get good exercise in clean, clear, breathable air. The choice is yours.

With the layout lines in place, bore a series of holes in a line and over a distance that takes the start end of the handsaw.

Pare down to the gauge line with a wider chisel; a one inch will work fine.

Insert the handsaw and saw to the line to the opposite end of the opening.

Drill a series of smaller holes or do the same as you did before. Your choice. I used a series of 3/16" holes and the battery drill for this this time.

I pared down to the line again.

Insert the saw and saw away.

Repeat this wherever necessary to remove the waste wood.

Use a tenon saw to cut walls for the pop up (or down) button for the QR mechanism.

Chisel out the waste with a 1/2" chisel.

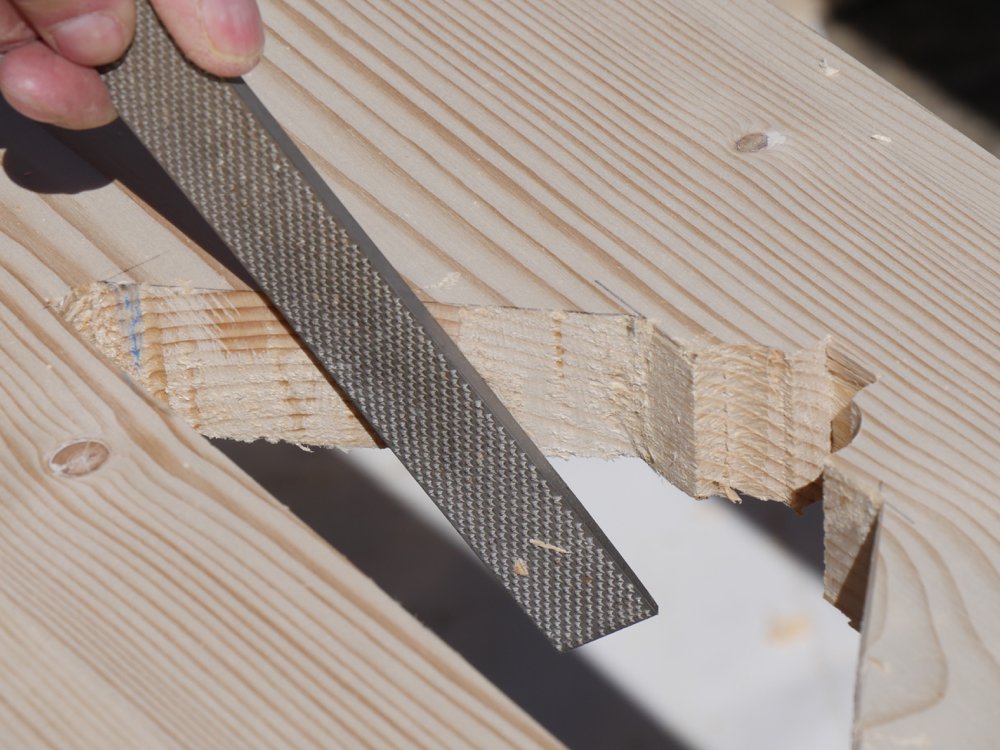

Use a rasp to level out any undulation.

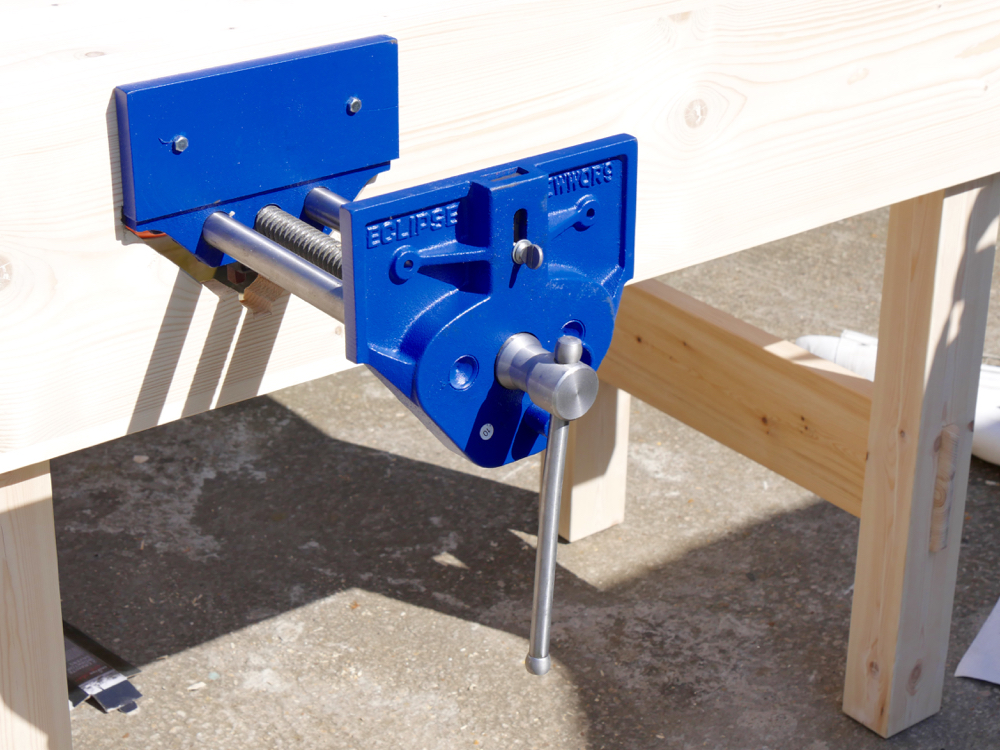

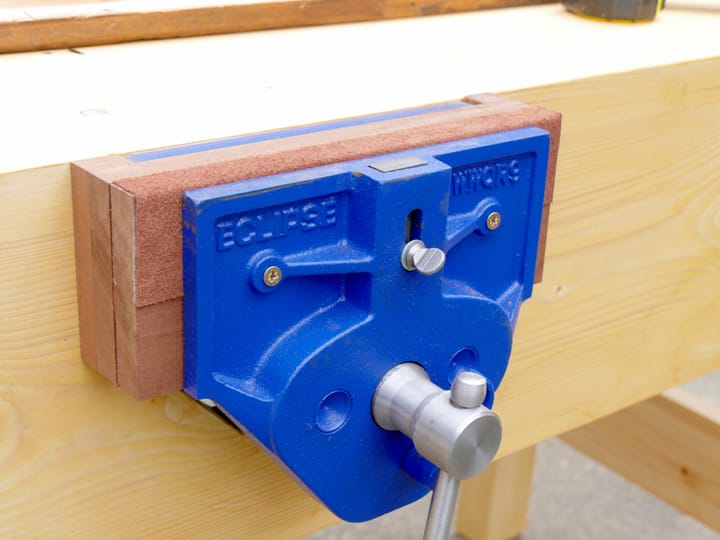

Insert the vise and see how it fits. The vise jaw should be 4mm below the corner of the workbench.

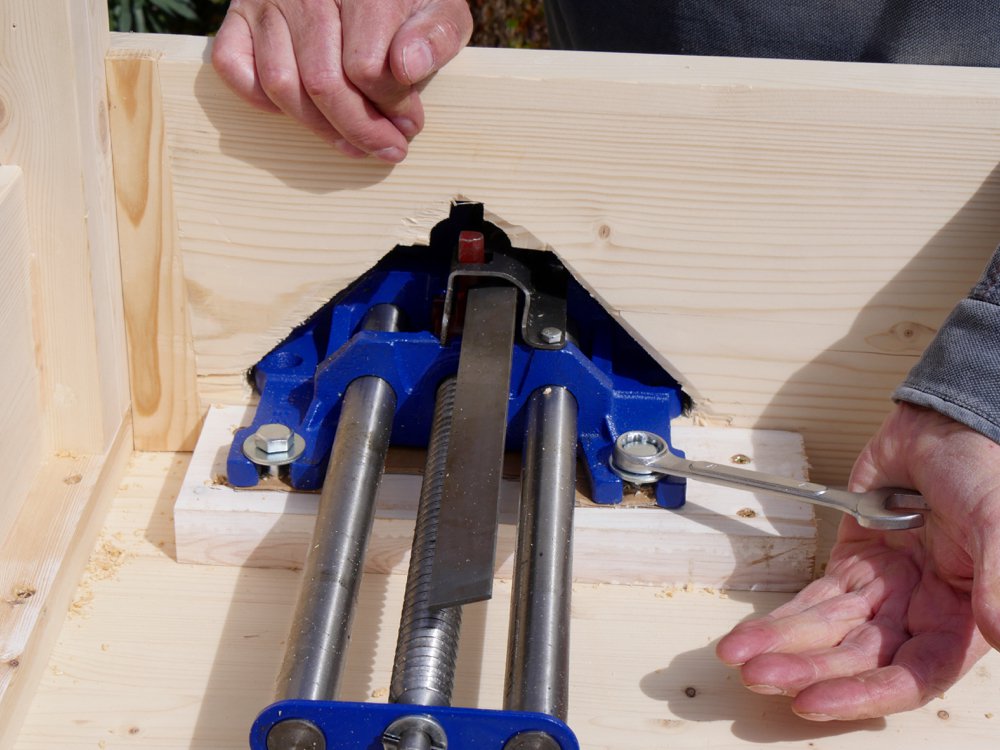

I turned my workbench upside down onto two saw trestles. This works best.

Pack the gap between the vise 'L' and the underside of the bench top. Use either solid wood or plywood for this. I also allow the packer to pass the vise sides for wider distribution of pressures and so on. I screwed the packing to the underside of the benchtop. Use thinner shimming to get the exact distant right.I used hard cardboard for this.

You can use bolts or coach screws but using bolts requires boring through the bench top and the resultant holes receiving the bolt heads will need plugging. I use both methods depending on what I have but here I used 5/16" coach screws to the underside section of the vise and the 1/4" coach screws through the face of the fixed vise jaw.

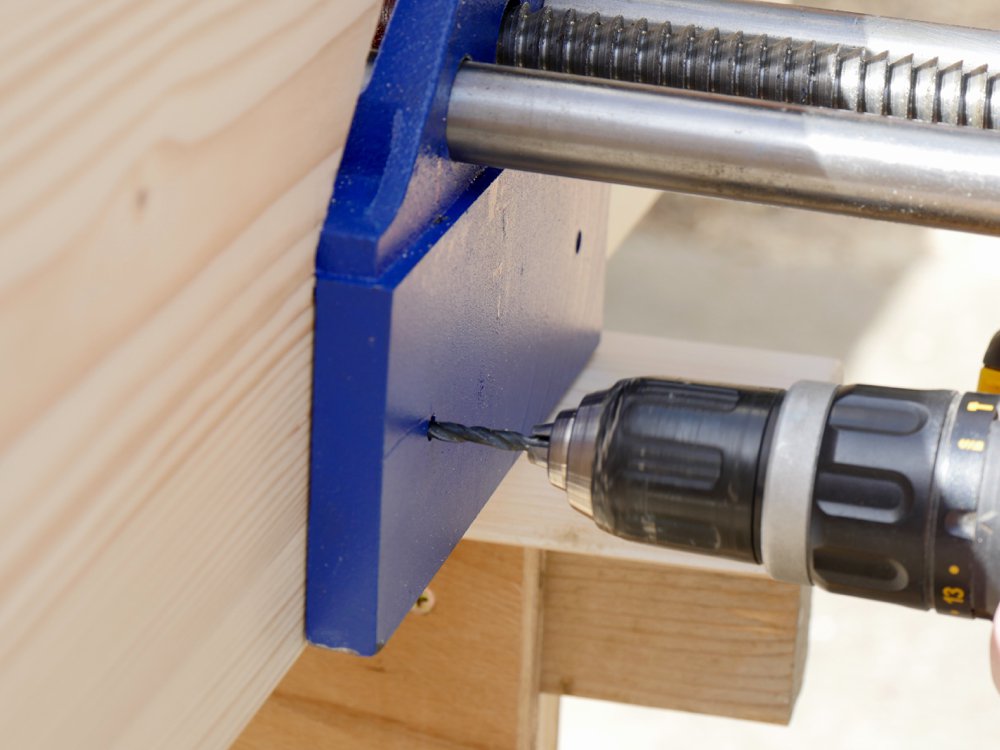

First pre drill pilot holes sized to receive the screw threads of the coach screws.

I chucked the screw head into the drill driver and finished off with a wrench.

By now you will notice that the holes inside the opening of the apron make it impossible to install coach screws there. The method I am using will be enough so leave these two coach screws out.

The vise snugs up nicely with extra turns via the wrench.

Next we will develop the wooden jaws (shown in top picture). The method I use makes this a wonderful installation.

Comments ()