Why Saw Teeth Profiles Look Mis-sized

I am often asked how to tell the difference between crosscut and ripcut teeth on handsaws visually. As you mostly know, I don't separate my saws by one or the other until the teeth get bigger than 10PPI and then I might sharpen say a 7PPI saw as dedicated crosscut or ripcut and keep two saws to that end. Mainly thats's because the larger toothed saws become unsuited to crosscutting whereas smaller toothed saws will aptly cut with and across the grain because the teeth are more commensurate to the grain fibres of wood.

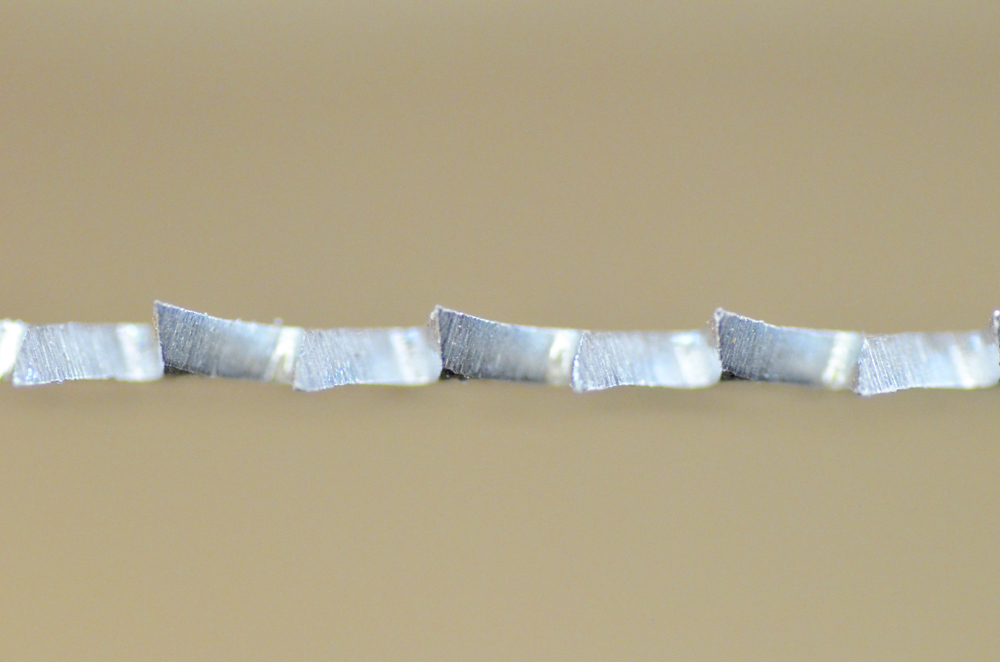

Some have queried why the teeth of the saw were uneven in height, with the teeth alternating high and low. There are a couple of reasons this happens. Sometimes, often, when you buy a secondhand saw the teeth can be way out. In such circumstances I often file the teeth to get to clean steel before I begin resizing and reshaping the teeth to even out disparity. After the teeth are filed thus, I go back in and top the saw teeth to get the height down and then I work either side of the wide flats atop the teeth to equal out the size. This is simply a question of forcing the file laterally and down into the gullet rather than just down into the gullet. On the other hand, when you see a crosscut saw from one side, the teeth can look remarkably uniform but with the alternate teeth being smaller than the adjacent ones. That's how it might look in this image here. Hence the question, "Whats the deal with the teeth here, Paul,? These teeth look like cows and calves? The term cows and calves meaning large and small or simply uneven. The reality is really a little illusional. These teeth are all the exact same height and size and the saw is brand new and sharpened only by the manufacturer.

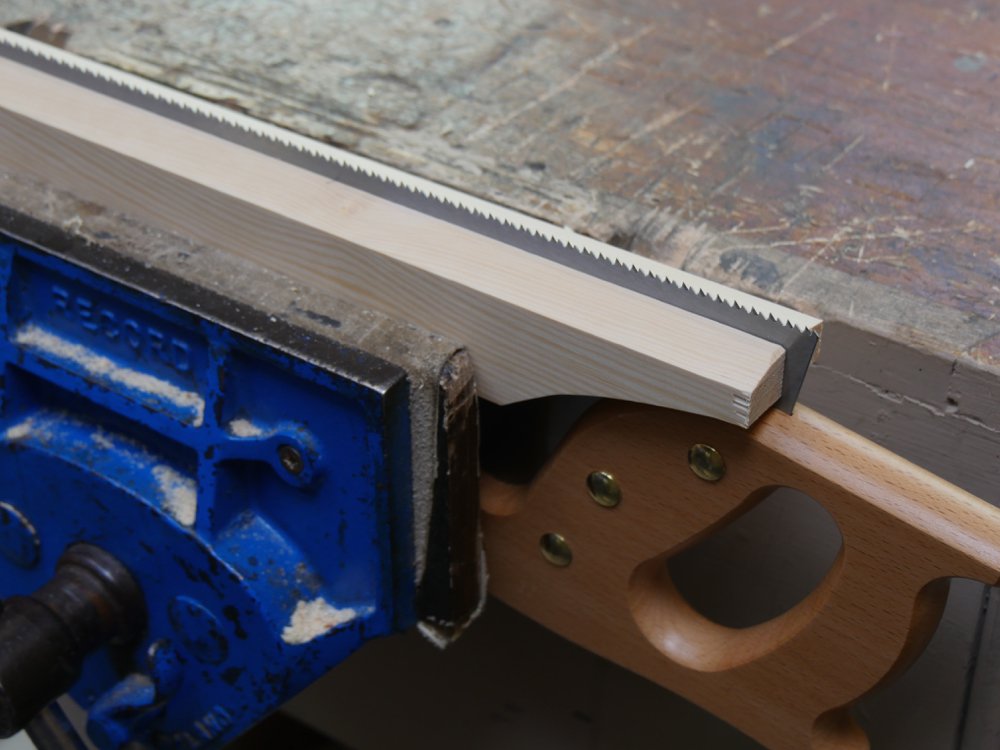

I took a couple of images I took for my book to bring closer visual for contrasting ripcut and crosscut tooth profiles. On eBay mosts saws will be sold as crosscut saws because most people selling them have no idea what the difference is.

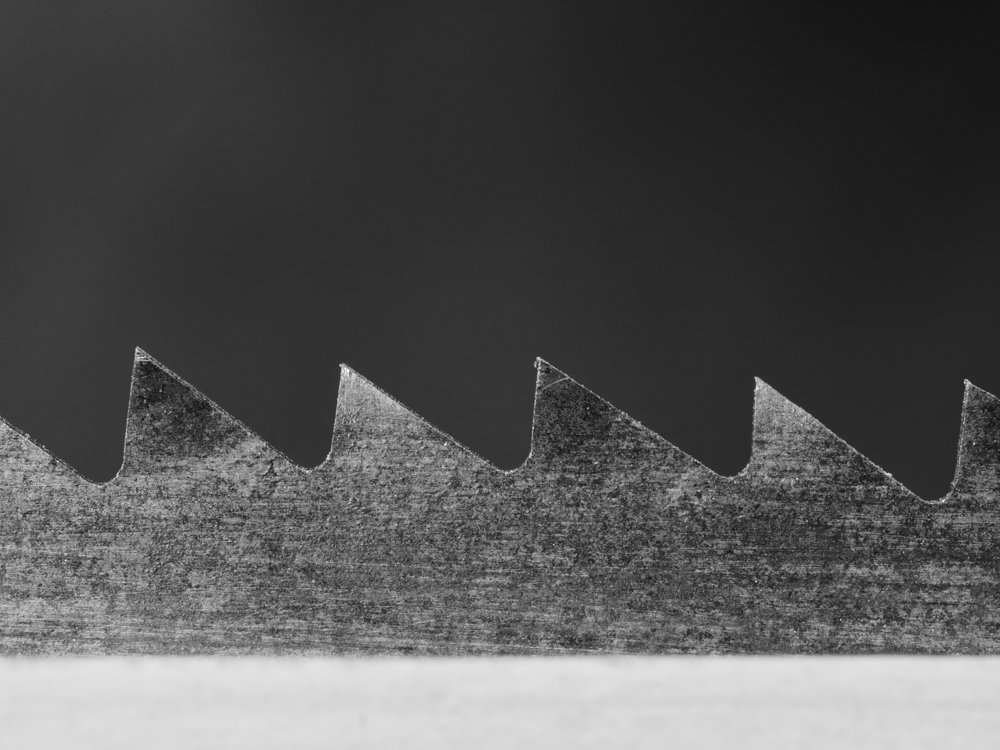

In this image you can see the side profile of the crosscut saw. You can see how only the inside of these teeth are profiled with twin bevels culminating in a pinnacle tooth profile and cutting point rather than a chisel point. By inside I mean that the tooth set creates an inside aspect and an outside aspect. Above you can see the teeth either side of the centre one are flat on the outside, but on the face you cannot see the teeth have the same profile as the centre one. This creates the dynamic of pointed teeth we need for some (not all) crosscutting work.

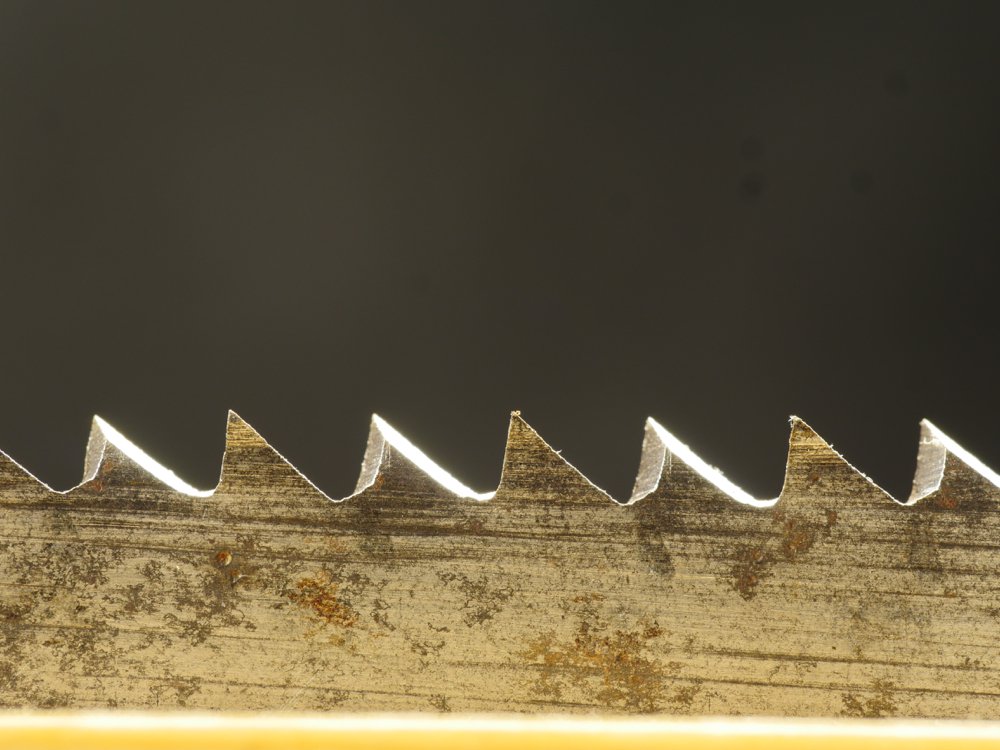

Here you can compare the ripcut pattern which has no bevelling to the inside of the teeth. This is the easiest of the two methods of sharpening; that's crosscut and ripcut patterns. The tooth sizing in the above images are exactly the same.

Here is a wider aspect of the crosscut tooth pattern so you can see that the teeth do look large and small yet the points are all the same height. It all depends on how the light catches the tooth profile.

Comments ()