Import Planes–Do/Can They Work?

Of course most of the time we might pass them up, but look what would have happened had I passed up the Aldi chisels six years ago. Seemed to me I should give a couple of inexpensive planes a fair try to see how they did and so I bought two from B&Q. The ask was actually to post a video or two on upgrading lower end/grade mass-made planes to see if qualities were issues that compromised functionality compared to say the old Stanley and Record planes and then generally to see just how well the planes functioned. I bought these two by different manufacturers but made specifically for selling through the same outlet to look over and fettle and see what we could do. These two came from B&Q, a DIY home repair and maintenance chain here in the UK and something of the equivalent of the Home Depot in the USA. Not quite the same and somewhat different because we don't build stick-frame homes with sheetrock walls for outer walls to homes and commercial buildings as is the general method of the USA and others following those patterns as standard.

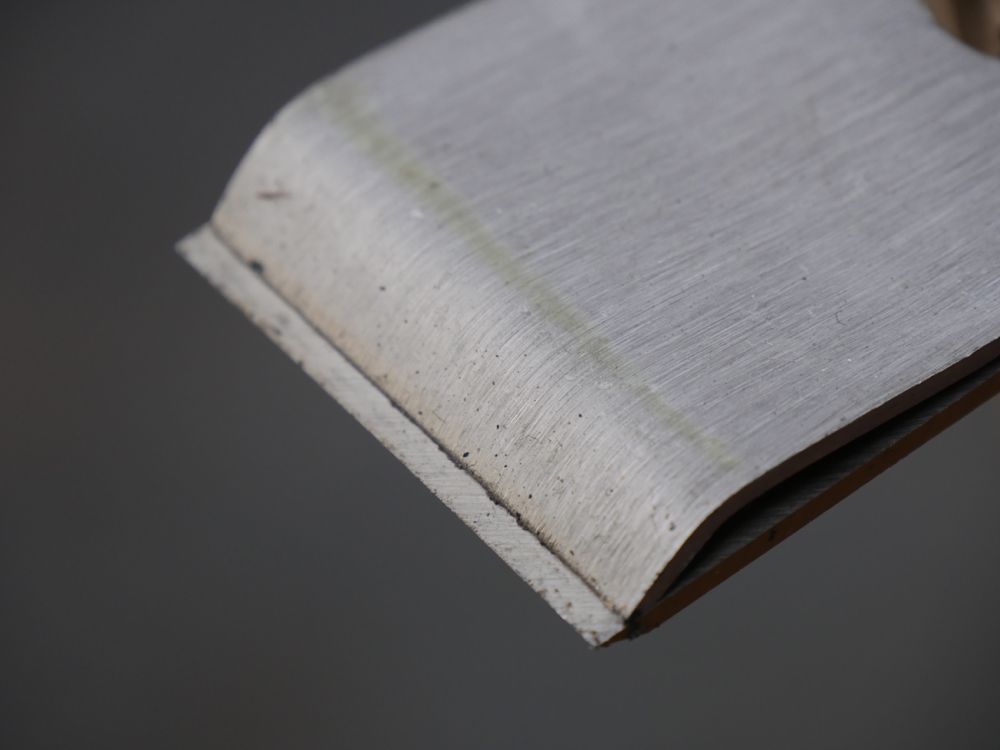

Just to start out I opened the box to see what I had bought. The two planes arrived bubble-packed side by side and cost £10 (yellow handled one) and £20 respectively. If anyone had taken the yellow handled one straight from the box and tried to use it as it arrived it would have gouged the wood and ruined whatever was there. The blade was locked into the body with the centre setscrew cinched way tight, so I suspect set with a screwdriver as no leverage on the lever cam could have got it that tight as it could not be unlocked using the retractive mechanism of the lever cam. So, mixed message here. One, the lever cam is for a quick set and then the setscrew is for locking in place. This very wrong! The second wrong signal is that the blade should protrude through the throat 3mm (1/8") to cut. Very wrong again! The blade would best be withdrawn into the mouth for aspects of safety as well as to prevent damage to the work in hand, but it couldn't in this case because the cap iron was set 3mm too far from the cutting edge so that adjuster was maxed out and couldn't withdraw the cutting iron beyond the threads and the angle of the yoke that sets the depth.

To me, these things seem minor elements of training for the assembly staff in Asia. Three twiddles here, a minor tweak there and little eyeballing and the plane could have actually worked out of the bubble pack. I must admit though, this standard was set by Stanley UK back in the 1960s because that's how their planes arrived from Sheffield.

I didn't too much care for the heavy dip-coat of oil that by the time you catch it has gone everywhere but there was no sign of rust. The yellow nylonny handles felt comfortable to me and funnily enough I can't always say that for wooden ones. In this case the mould seam left an exaggerated line that will need removal before use or a blister will come as result.

We will film the first plane this week and let you know how we go on. M gut feeling is the plane will work. How well I will let you know. I will say this. It definitely feels better than the Harbor Freight #4 I did the same thing to a few years back. U think that they have changed theirs from the rosewood handles to plastic now. They give you a block plane including in the $14 but that doesn't even make a door stop never mind work.

More on this plane shortly.

Comments ()