Rasps and wood - two key ingredients

On rasps for cabinet making

On many of my projects I use cabinet rasps and others for more detailed work because they remove stock fast and when well made surfaces shaped with them need only moderate refinement. I just finished off the latest video series on chairmaking where we make one of my designs in European what oak. To take care of some of the shaping I used a 10” cabinet maker’s rasp and used one that I have been using for the last couple of months or more. This leads me to a recommendation I am glad to make.

When I come across a tool that works well I like to pass on the information after I have used it, verified its quality and qualities and evaluated it for longevity. I have done that with expensive tools and less expensive ones equally, but don’t generally recommend tools that are low grade unless there is a reason. This usually occurs when I find a tool intended for another completely different purpose but can adapt or alter it for woodworking. A knife intended for cleaning the hooves of sheep can make a good hook knife for instance. And here’s is a knife originally intended for a foot knife to dress sheep and lambs feet but was adopted by UK electricians for peeling cables and is generally sold as an electrician’s knife now. This knife is the best pocket knife for me and I also use it as a layout knife and have had one of these in my pocket for a decade or more now. The blade is strong and thin, it takes and holds a good edge and it’s super strong. Yes, the Stanley folding pocket knife is still the ultimate knifewall knife I use at the bench, but this is a close knife to carry around. I choose less expensive tools over expensive ones if they seem to be a tool that offers a working tool of lasting quality.

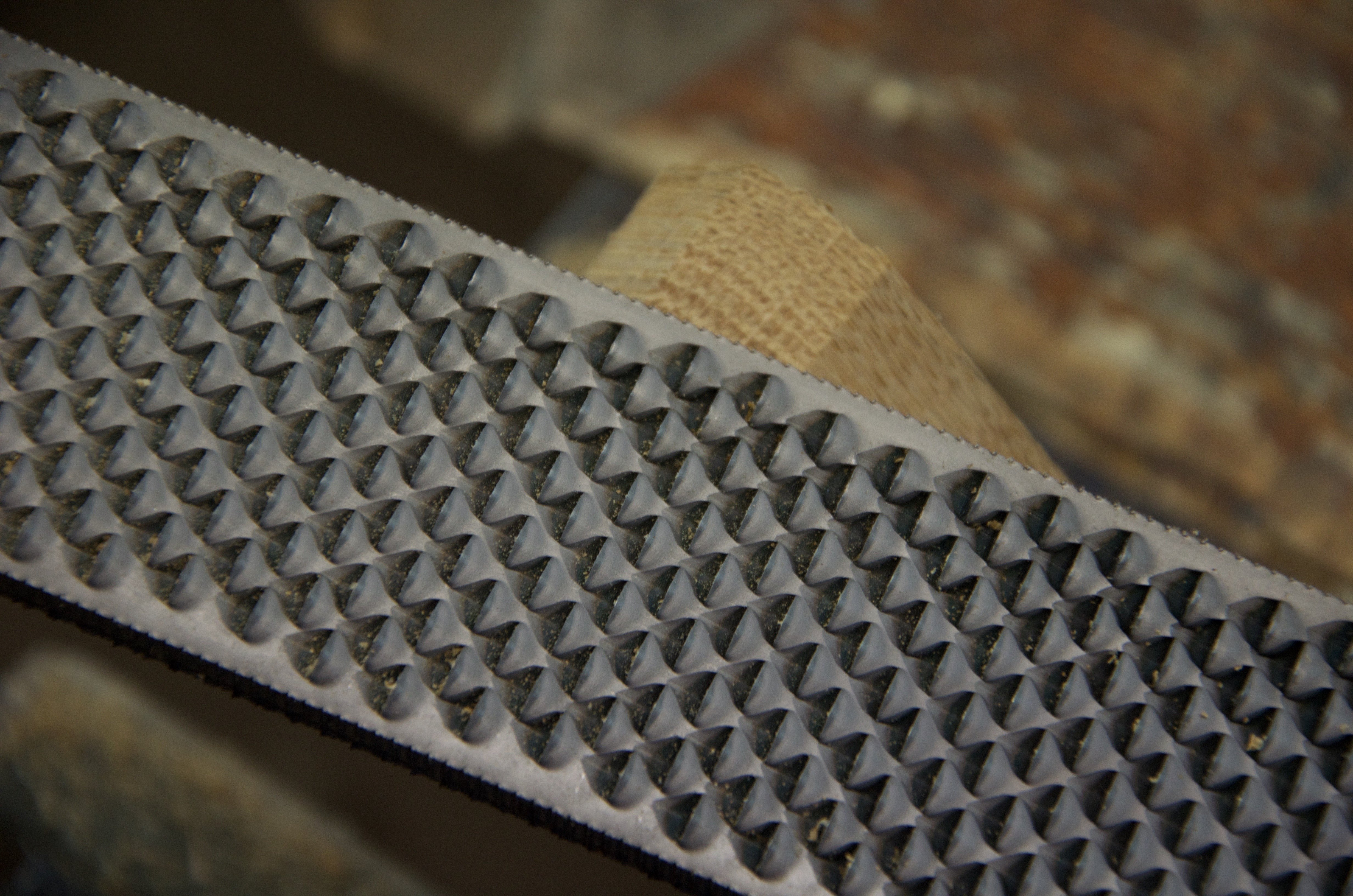

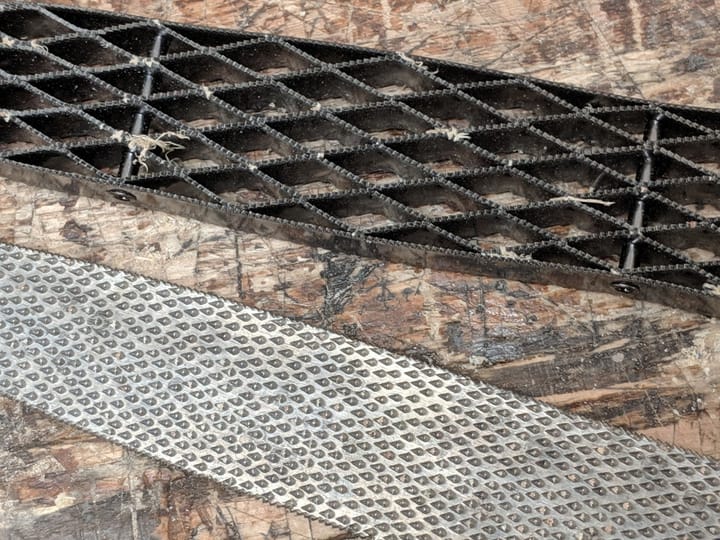

On then to a new favourite rasp that works wonderfully even though it’s not hand stitched. This rasp is from Tome Feteira in Portugal who gladly ship worldwide to almost all countries and they will ship just one item. Personally I might consider three or four different stitches from coarser to fine. I think one of these will indeed last you years of use going off my use of it so far. The hand cut 2455-250 #2 and #3 cuts work well, but you might want the coarser #1 for fast removal of material.

What I look for in a rasp is no different than most tools. I generally use a few rasps including the more expensive Liogier, Auriou and others, but this rasp is very inexpensive and it cuts so very nicely, removes stock fast and it holds up to all of the woods I have used it on, which includes rosewood and ebony, all the domestic hardwoods you can think of and then the hard knots you get in spruces and all the pines too.

Different stitches, sizes and so on, #1, #2 and #3 determine smoothness, so grading and grade choices becomes best suited to task. #3 is the smoothest. I picked this as a favourite from the ones I ordered. It’s one that compares with others made for over a £90 and gives me excellent results for under £20.

On wood supplies for the next two projects

Some of you started on our latest online broadcast through woodworkingmasterclasses last week or so. It's the cherry Shaker sliding dovetail seat/stool/bench and in the UK you've asked where to get cherry from and I want reiterate the service offered by Scawton sawmills. They will ship any wood in any quantity to any destination and their prices are some of the best I have found. Scawton provide several European hardwoods like oak, ash, cherry, walnut and others. Order a specific wood type or do as I did and order a few board (square) feet of each. The cherry I bought was nice to work ,with the typical pleasant character cherry has as a hardwood. I’m hoping you are enjoying this series and learning the sliding dovetail at the same time.

The oak chair I made this week (above) for the next series was top notch too. I bought some lovely 8/4 (2”), from Scawton sawmill, that came to me at 2 1/4” (56mm) for leg material and book matching and that gave me the legs and back support rails for this chair. The 4/4 (1”) was sequentially cut and gave me a good selection. I am not saying that that will be the norm for sending out but I did end up with consistent colour as the boards I used came from the same tree.

Of course I enjoy making all of the projects for woodworking masterclasses, partly because I love training and teaching people and outreaching the globe with a new message that gives more meaning to my work than almost anything I’ve done so far, but also because I'm a maker. I also want to counter this present culture of naysayers who say you cannot make your living from working wood and be a furniture maker or any other woodworking trade. I would say that it's all the ore viable if you are a hand tool woodworker as part of your skill sets. Most of these guys advising that you can't probably never did or couldn’t make a living and so they say you can’t either, but it’s not at all true. I believe a small company of crafting artisans, three or more perhaps, can share their abilities and skills and be a viable entity if they learn what we are teaching. Most of my life has been spent working alongside people I have trained and most of them are woodworkers with guts and we had plenty of work, months ahead, and at one time 2 1/2 years ahead.

So, anyway, here I am still making, still teaching and of course sharing my life with friends I work with and friends beyond anything I ever expected around the world.

Comments ()