The Joiner's axe—Part II

Most axes I've seen others use and picked up have rarely been sharp. Do I judge by this? I suppose I do if it's a joiner's axe and not a kindling axe or a felling axe. Joiner's axes are working edges mostly and sharpened to the same level as a chisel or a plane. I do keep a couple for wedges though and these can be dull because they continue the start work of the splitting axe if say you are parting wood.

An axe splits straight grained tenons and housings quickly and can be used for paring when used two-handedly like this, to pare down to the lines. As a young man site work relied on the axe for much work including the removal of half an inch from an odd sized refit door. I made many a tenon for a large door frame this way too; cut the shoulders with the handsaw and then spit cut and pare. It was fast and effective in woods like redwood pine and oak. Woods we used a lot.

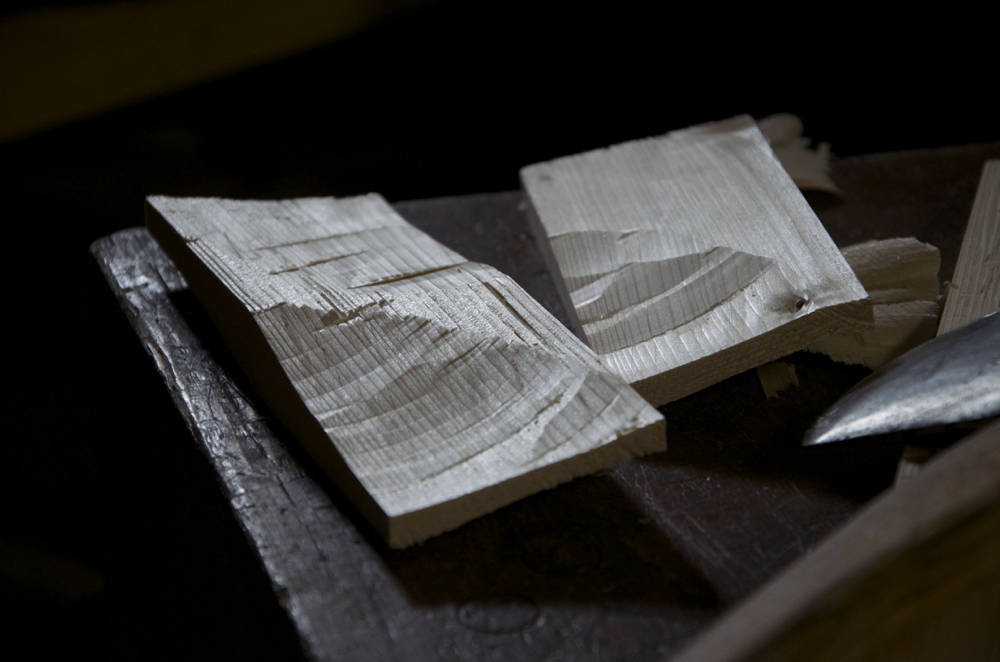

Here a recessed housing is shoulder cut and then chopped to remove the bulk of the waste in a matter of a minute or so. Today's carpenter makes a few cuts side by side across the grain and to depth with a skilsaw and then switches to the ripping claw of a claw hammer to rough down close before paring with a stubby chisel. It takes about the same time, but it's funny how the latter still seems excessive and cruder to me than the well-tuned axe. Perhaps it's the screams of the skilsaw, the need for electricity and the excess of all of that somehow.

Here is how a plug is cut. Notice the thumb is not hooked and hanging over the top of the plug piece but tucked out of the way. First I chop one corner section of the 'propellor' as shown...

... and then I turn it around and chop the opposite side.

I then turn it end for end and so do the same. This makes two plugs in each length of pine. The plug is generally driven between the bricks, left shy of full depth, cut off with the panel saw, and then hammered home with the back of the axe.

In restoration of the old Victorian houses I always cut a hundred rough-cut plugs at a time and then fitted each one on my knees to the relevant opening for a perfect tailored fit. We only used dry wood left by the pot bellied stove for a day to make sure there was no shrinkage once driven.

Here is how the plug looks from the end. They are generally custom sized according to the gap in the bricks.

These plugs were more than a mere friction fit or a beaten in wedge. They were well thought through and strategised by men who cared about life and longevity. We can look at how these work next.

Comments ()