Saw files--lasting qualities

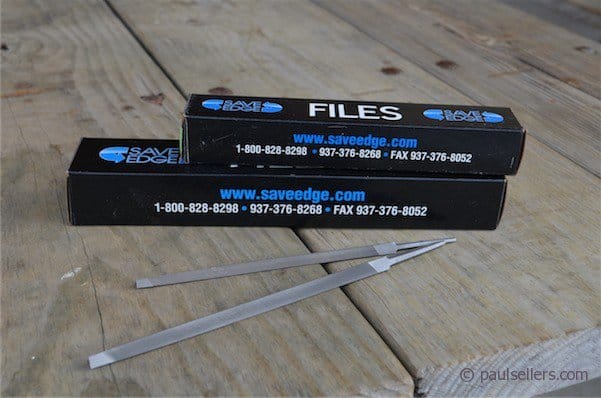

I use saw and flat files of different types considerably because we have fifty student saws that need sharpening regularly and of course if a saw file barely sharpens a single saw nowadays that makes DIY saw sharpening prohibitively expensive. I bought three of Nicholson's files two weeks ago to make sure they were still consistently bad and nothing’s changed. They are still made in Mexico not the USA and quality is still substandard. I only managed to get down two thirds of the length of a 22" panel saw with 10 PPI before having to rotate to a fresh corner of the file to do the rest. They are £8 a pop here in the UK so that makes them three times the USA price for a 6” extra slim taper. Anyway, I did this to make sure I wasn’t misinforming you as to the the demise of quality in the Nicholson files and I am not. So my thoughts on files are that as far as a decent file goes I have found other makers of saw files for saw sharpening that work well and I have tested three types out that work well. Here `i want to talk about the Bahco saw files and also their flat files which I use for sharpening scrapers and topping saw teeth.

Here in the UK Workshop Heaven carries the fullest range of Bahco saw files and flat files. There are many US suppliers too

Understanding the dynamic of saw files is important and many file makers like Nicholson seem to have lost their way if not their moral obligation to the USA as a US company once providing good value, quality product. Losing their connection to past working knowledge of what their forefathers worked hard to establish is a sad thing because a good reputation is hard earned and second to none. Many distributors also isolate themselves from accountability via eBay and other online sales outlets. If they choose to be non accountable that’s up to them. I am sure many sales outlets actually like the fact that the Nicholson company producing inferior files instead of the superior ones they were once known for. Radically shortening the working life of their files means customers will return all the sooner as there is no longer a generation that understands that at one time a Nicholson saw file would sharpen a saw 30 times or thereabouts depending on the hardness of the steel in the saw plate being sharpened. Nowadays that has been reduced to possibly two or three but more likely one or two.

Six-sided files with six cutting faces

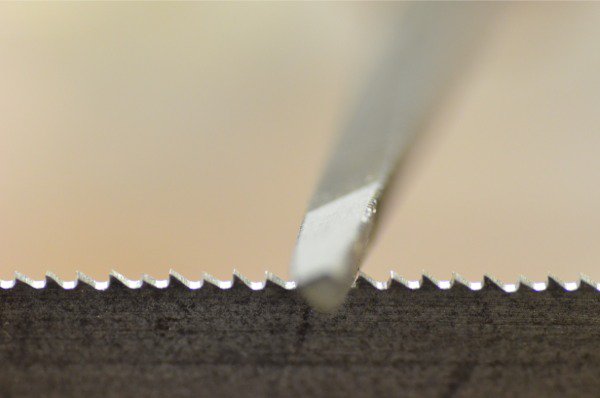

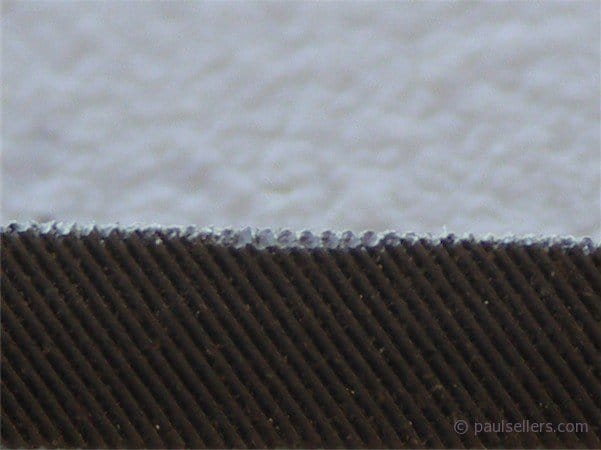

Putting the files under magnifying lens does help to see what’s happening at the cutting edge on the files and in the past I talked about there being six sides or facets to a triangular or three-sided saw file and not three as it seems — three large facets and three small or, actually, narrow ones at the corners. Without these as working edges the files would not work because the edge is too narrow and fragile to retain viable cutting edges. In other words you cannot just take the three flat faces and make a saw file that way. You must have six. These files are different than three-square or three-sided files used in engineering. Some of these files have what we call a safe edge; a corner that's made specifically not to cut internal corners but cuts into the faces forming the internal corners for refinement of some kind.

File tooth profile of files

Files are made with a series traversing the face of the file with parallel teeth. Each of these teeth are formed with two bevels to them. One is the steep and deep cut that creates the main gullet by forming a vee groove across the working face of the file at a 60-65-degree angle. The second cut refines the back of each file tooth with a secondary bevel that then creates a back relief cut to first strengthen what would otherwise be a weak cutting edge and then provide a relief at the back of the cutting edge. Whereas the back bevel resolves one problem of a weak edge, it also creates it’s own problem if the back bevel is level with the long axis if the file. This back bevel of a few degrees allows the file to cut the steel without riding the work. Without this back relief the file would not work.

The problem I have found with many files is that the narrower edge forming the corner edge-fractures during use, often this happens on the first few strokes in the saw sharpening process because of the stress placed on so narrow an edge. A file is a high-demand piece of equipment. If the edge is too soft then it won’t cut and because it dulls or turns immediately. If on the other hand it’s too hard then it will edge fracture on the tips or the whole tooth will simply break away. Either way, the file is rendered useless for saw filing because the bottom of the gullet where the front and back of the teeth interconnect must also be filed and that's the reason that the saw file facets are interconnected by the narrow flat face.

Inconsistent hardness is another problem affecting the files. This results in localised and intermittent fracturing along this narrow edge of the saw file too, which then causes difficulty through jerkiness in the strokes. Because you can't necessarily see the narrow edge, you can’t understand why it’s happening and it’s this edge that Nicholson files are now best known for in terms of fracturing and breaking off of teeth. Occasionally, even on good files, a corner will have all the teeth fractured during manufacture and end up being sold. This is just hard luck for you, but usually the other two corners will be fine. On the Bahco files the corner teeth are usually clearly defined and well shaped with a good flat, chisel-type cut over the narrow width. Other files seem quite random and this means that the small corner can be less than useless.

I recently had to advise people not to buy the Bahco sliding bevel if they were looking for a tool that worked. The beam didn’t lock at all in the stock and slipped all over the place on the 20 or so I tried out. Bahco were quick to respond but offering me another sliding bevel didn’t resolve the issue for me. With their saw files however I have found them to be consistent through the years. Here are my choices for the four saw files I generally find take care of all my working needs for saw sharpening. I also have a couple of 10” single cut flat files for sharpening scrapers and topping (jointing) teeth and other metal working needs. I do like Bahco Oberg single cut files and I use a couple for my sharpening needs. As far as files go I do enjoy the Bahco files. Here are the ones I use most:

Saw Files

Bahco 4-187-07-2-0 -- X Slim 175mm (7")

Bahco 4-188-06-2-0 -- XX Slim 150mm (6")

Bahco 4-190-07-2-0 -- XX Slim 150mm (6") Double ended

Bahco 4-188-05-2-0 -- XX Slim 125mm (5")

Flat Files

Bahco Oberg 143-10-1-0 250mm (10") Millsaw Bastard Single-cut flat file

Bahco Oberg 138-10-1-0 250mm (10") Millsaw Single-cut flat file

Bahco Oberg 1-100-12-2-0 300mm (12") Hand Hand Second-cut flat file

Comments ()