Questions Answered - On Brace and Bits

Question:

Hi Paul,

I did a quick search on your blog and can't find any information on brace and bits. I wonder if you have any thoughts on what to look for/brands to pick/avoid when choosing a second hand brace and bit. It might make a good idea for a future blog post?

thanks,

Matt

Answer:

Thanks for this question Matt. Brace and bits don’t take the limelight too often any more because of the power drivers everyone reaches for so readily. There is a silent strength to the brace and bit that quietly takes it’s place in the hand tool shop that so readily does the work steadily and without the buzz of Dewalt, Makita or Milwaukee. Most of the time the brace and bit will create cleaner work than the power tools will simply because they are cutting and slicing more readily and without the excesses you get with power equipment.

A good brace is virtually indestructible. I have owned one of mine for 50 years and it will go for another 50 I am sure. There are things to look for that are necessary for them to work well.

The parts to the brace need light, periodic oiling. Often this is neglected in finding a secondhand brace. The centre handle works well if oiled and a drop in the gap will ensure it stays moveable.

The pad here has an oiling hole and two or three drops works fine there too to keep the race of ball bearings free.

About the bits

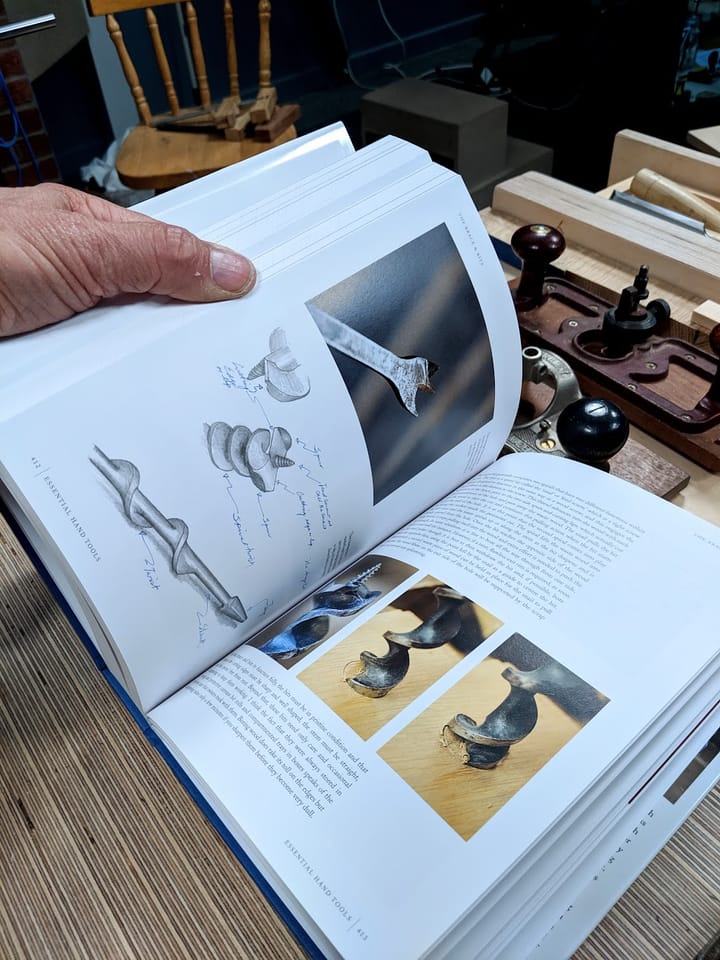

The bits need to be in good shape and so below are some pictures to show flawed bits and what to look for when you buy.

Bits have two key cutting aspects that bore into the wood. The first cutting aspect of the bit cuts the circumference of the hole with two spur cutters that extend each side of the business end of the bit. On most bits there are two spurs, but sometimes there is just one. Slicing a circular line cuts across the fibres in advance of a second or later cut that comes from two inclined bevels inside the two spurs and on either side of the snail. As the bit rotates to form the opening cut with the spurs, the cutting inclines slice in a paring cut and at the same time lift out the then severed waste. Each rotation of the brace pulls the bit deeper into the forming hole. Combining hand and arm pressure with the pull of the snail at the tip the bit readily removes the waste in most woods.

The spurs on the bit above stand [rode of the bevelled area inside the spurs so that they cut beforehand. After much use and neglectful filing, these spurs can get too low and when level no longer sever the rim fibres to the entrance of the hole. This results in torn fibres, so watch out for this when buying as they can be extremely difficult if not impossible to restore.

Hardwoods such as ebony and rosewood, boxwood and so on are much harder to bore.

Here the ratchet needs regular oiling too.

Inside the chuck are two jaws held with a spring that opens up the jaws to receive the square bits.

Turning the handle tightens jaws.

The pointed snail shown above has a spiral that pulls the bit into the wood. When it’s broken and blunt it usually will not pull into the wood. When it’s gone it chews away the wood and wont centre.

Above the spurs are broken off or filed away as you can see. They do not score and cut the entrance to the hole or the wall and the surface on the outside is always fractured and torn.

Here is a larger bit with the same problem.

Compare the two holes here. On the one hand the 1/4” bit has no spurs and the hole is spewed out. The same sized bit with spurs cuts a clean wall and clean rim.

Here is an auger bit made for a power driver.

These bits work well in a swing (hand) brace too and although they have a a single spur they do cut a clean walled hole with a clean rim. Another thing is that they are readily available, cut as well and give good results. Rather than not have bits I think it is better to have one or two of these around to work with.

These two traditional pattern bits are both patterns commonly made. One is referred to as a jennings pattern, that’s the one with a steady and even twist, and the fast cut or Irwin pattern. Some say that the Jennings pattern works best and stays more steady in the hole as you bore. I find that that’s true, but the other still works fine.

here is how we generally use the brace and bit. There are other holds too.

Comments ()