Oil Stones and Boxes, Factory-filled and Finishing

Question:

I just made a set of these for my oilstones. Unfortunately, I’m going to have to redo them now because I look at yours and then I look at mine and then I look at yours and then I need new boxes that look like you made them and not me!

I’ve heard one should soak their oil stones in their preferred honing oil before using them and then let them sit in a puddle of it in the box when not using them. Most of mine came from garage sales so my honing oil is likely the first oil they’ve seen in 30 years, and I didn’t soak them, I just oiled profusely when I sharpened and if the stone soaked up the oil, I added more. It might be yet another myth to be busted, but how would that work with boxes like these?

Answer:

An unfilled sharpening stone looks like this - dry!

And a filled stone looks like this, oily!

The better quality stones are factory-filled which means they were left in baths or in some cases pressurised containers to force oil into them more quickly and then set aside to allow all excesses to drain off before packaging and shipping out. More inexpensive stones are dry and that means they must be soaked in a light machine oil in a tray or bucket. Whatever you saved in buying a cheaper stone is then lost in buying in the oil. It’s fine to oil non-filled oil stones profusely as you say, but the factory-filled stones need so little oil once filled I think its worth the extra cost.

I have now finished my box and coated it with three coats of coloured shellac to match the original colour of the old table as it was. Shellac isn’t affected by Three-in-1 oil, which is my preferred honing fluid, so adding finish helps to keep things clean with a quick wipe with a rag. Most any finish will work, water-based poly or indeed oil-based poly too. Shellac is fast to dry and less problematic to apply than most other finishes. I used dyes mixed to match the colour I needed.

The lid should be fitted so it’s slightly loose for quick and unhindered removal. I finished the box inside as well as out. People often use the term lubricate the sole but the oil is float off swarf from the stones surface and keeps the cutting surface from clogging which is what happens when you use the stone without oil or honing fluid.

Apply a small puddle of oil to the surface and start honing back and forth.

When you reach the edge and feel the burr you can flip the stone over for a finer surface if its a combination stone with two abrasive grits.

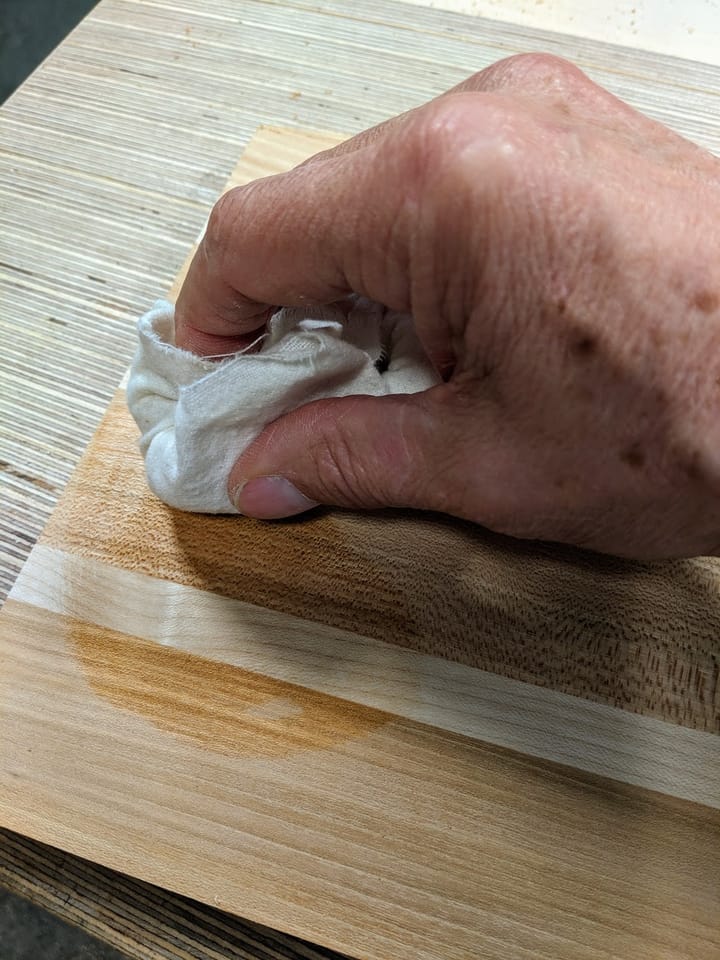

When done, wipe off the oil and the swarf ready for stowing.

Here is the finished box.

Comments ()