Do Moulding Planes Mould End Grain?

Question:

Paul,

It’s interesting to see how you use moulding planes for moulding things like tabletops and so on and I really enjoyed watching how you moulded the picture frames, but they don’t seem suited to working on end grain. Is there a strategy like special skewed irons or what else can you do to deal with end grain using moulding planes? Scratch stocks, skewed irons and what about say one of the combination planes like the #45 for moulding too?

Thanks,

Paul

Answer:

It’s funny how many people think moulding planes don’t work too well on end grain and no one really knows where this came from. For two centuries most moulds we see on end grain came from moulding planes and not scratch stocks. In some cases it’s true that there are sometimes issues with moulding end grain, but the cases are more remote than general and mostly related to softwoods and soft-grained woods. It’s not usually a problem in hardwoods but in softwoods the compression between hard and soft aspects of the growth rings side by side on the endgrain can be a problem. Soft-grained woods are hard to mould on end grain but easy enough along the grain. I think people pick upon that and think I’m cheating when using pine to make the moulding look easy. There are facts that make functionality practical and effective so this is what you should know.

1: All of the softwoods in the softwood genre are more problematic but far from impossible to shape. Sharpen up often and shoot for top levels of sharpness with no half measure. If possible use a light knifewall or even staggered knifewalls between the corner and the extreme width of the cut. These serve as stop cuts, which prevents undercutting the main body of wood as the fibres are severed before the iron.

2: Skewed irons do indeed assist in the endgrain profiling of wood and especially so on softwoods as they slice- or pare-cut at a skewed angle. Many softwoods have little difference between the hard and softness of the growth rings, Eastern white pine, for instance, but when the pines are soft they grain compresses and often tears under pressure of the forward thrust.

3: Most hardwoods, mahogany, oak, walnut, cherry, maple and so on, will mould well using moulding planes as long as the irons are sharp and kept sharp by frequent honing throughout.

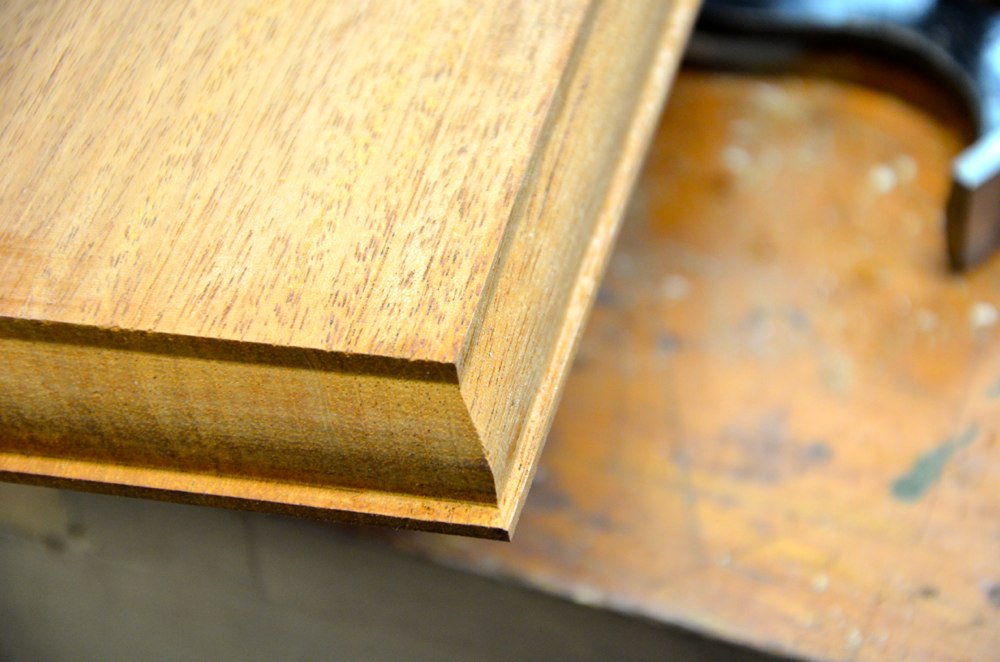

Unsanded mould from the plane

4: Moulding planes self sharpen. By that I mean it’s incorrect to lift off the plane on the returning back stroke as some people do and say. The plane stays in contact with the mould the whole time. This saves multiple realignments at the start of the cuts when you land the plane each time. The second benefit that’s generally overlooked is that the moulded stock hones the bevel on the returning back stroke and this keeps the edge sharper for longer, which I find is the same with all planes by the way.

5: Scratch stocks will work generally but mostly we use scratch stocks for curved work such as oval mirror and picture frames, carriage doors and such.

6: Moulds start with almost no material being removed and gradually, with each successive stroke, the surface cut increases until the final level is achieved with a full width cut that followed the whole profile. So, the cut starts easy and finishes hard.

7:The famed and abandoned multi combination planes were a poor substitute for moulding planes dedicate d to task and shape. The idea was that the combination plane had most of the cutters you might need for moulding, rabbeting and grooving wood. The latter two worked well but the moulding cutters were generally a dead loss. What Stanley Rule & Level never could compensate for was the loss of matching sole that followed the profile of the iron as the cut progressed. That being so, the material had no compression before the iron on the forepart of the lane over the width of the mould by a sole and so the grain would lift in the cut and tear. Now I am not saying these planes didn’t work some of the time, but they were unreliable on the commercial side. They are fiddly and awkward to set up and time is money on the shop floor so that’s why we have so many of them in good condition!

Obviously you cannot plane through-cuts without back up on endgrain profiling in much the same way you can’t always have free cuts on moulding machines such as spindle shapers and routers. I usually clamp a continuing section of wood to carry the plane through and prevent the speltching (blowout US) as shown.

With sanding and a coat of finish the profile is perfect.

Oh, just in case. It is harder to mould end grain, physically I mean. It's more of a workout and takes more effort than going along the grain.

Comments ()