On Fractured Cutting Edges To Edge Tools - Part I

My thoughts are these. I am afraid we do tend toward living more obsessive lives thinking it's this or that that makes us good craftsmen and women when in actuality most woodworkers we know don't earn their living from the work they do in woodworking. This strange condition has created an equally strange dichotomy that then directly influences how we prioritise what we do to be woodworkers. If for instance we are 55 years old and retired with a half decent pension we might spend half a day sharpening a few chisels and know that there are no real consequences that affect other things and in those few hours we simply enjoy the freedom from the various constraints we once had to live with. On the other hand we might work two jobs, have a spouse and kids to be with during non-work time and want ensure everything is done to maximise efficiency. Our personal circumstances are all diversely different and so too then the criteria we set ourselves for working wood.

One thing I see is that somehow, often, we might find ourselves proving to the rest of society that we are not just, well, ordinary when ordinary is actually a good place to be for any artisan. It's respectful and honest, open and transparent and modestly humble - hopefully anyway. When you meet a true craftsman it's almost always very humbling to watch him at his work. You always feel as though you invaded his or her workspace, albeit unintentionally and quietly. Very different than with entertainment guru woodworkers. It’s really a very rare experience if and when it happens to us and we treasure the moments. I suppose my thought is that we should leave the super-manhood, super-womanhood to politicians and actors, one and the same often, and get on with what we feel called to do with our hands. Some people say, "Just do what your passionate about." Well, that's not really always too realistic and it's not so easy in today's culture because it takes more a made up mind, not passion alone. Being passionate can be one of the ingredients to driving an issue, but not the whole and it doesn't often pay the bills. People who say follow your passion should possibly review the word and reconsider whether determination might be better, or convictions or dare I say it without sounding old fashioned, your calling or vocation. Being practical does fit too and that's what being a craftsman is about much of the time; resolving different materials into creative pieces to wear, sit on, sit at, lay on, lift from, place on and even ride in and fly in or listen to. Of course the list is unending. Being a crafting artisan is more about honesty and integrity than being a business person or a smart alecky bod trying to sell something only to make money and building a bank account. We artisans, we've mastered our craft and in addition have speculatively invested much time and energy and finance in our making and now we must sell or starve. We stand in the freezing weather and conditions no employee would for hours and days to make our business work. We’re not born salesmen but we must sell what we make. We didn’t make a hotdog from a can or flip a burger and add mayo and mustard and a piece of lettuce, we made something with our hands we feel has real value. We’re not managers but we manage. We do these things without a contract of employment and with no job description mostly because no one else could, would or even should do it. Craft shows tend to have a large percentage of 'here I am, entertain me between meals' people. They’re not usually looking for furniture or a hand made violin but interested passersby. I say all of that because somehow we crafting artisans, whether arrived or on our way, have started to become increasingly more fanatical about sharpening and flattening our edge tools than actually mastering craft skills. Somehow it's become something of a platform for performance and this leads me to what I want to try to help people see.

As I have said, we have become something of an obsessive bunch when it comes to the different elements of working wood; sharpness has become more and more obsessive. Now we are not talking about the violin maker seeking sharp levels for clear tone from the wood and who uses wood so soft, unsharp gouges and planes would bruise rather than cut the fine surfaces he strives to achieve. His standards parallel the levels needed for severing tissue by the surgeon's hand, not the bench joiner chopping mortises and cutting a few dovetails.

It's unfortunate that since the demise of ordinary craftsmanship we now turn to guru wood writers and not wood-wrights. Woodwrights are no longer there to give us our information of course. It's true too that the sources of information become more and more questionable. Three recent sources of information teaching on sharpening techniques I tracked back to tool catalog and online sales people selling products for sharpening. Most of the information they have is not new but regurgitated. Each phase of sharpening change marks another saleable product and so we see Japanese water stones added to carborundum stones, Arkansas stones and Washita stones and then came diamonds and abrasive films, diamond paste and flattening stones. The list goes on.

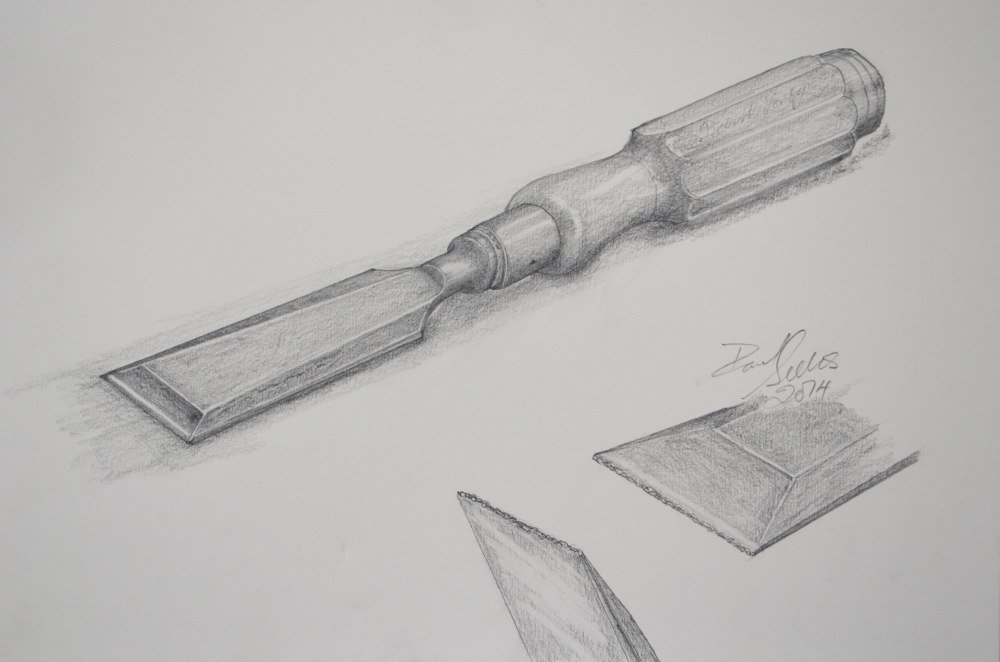

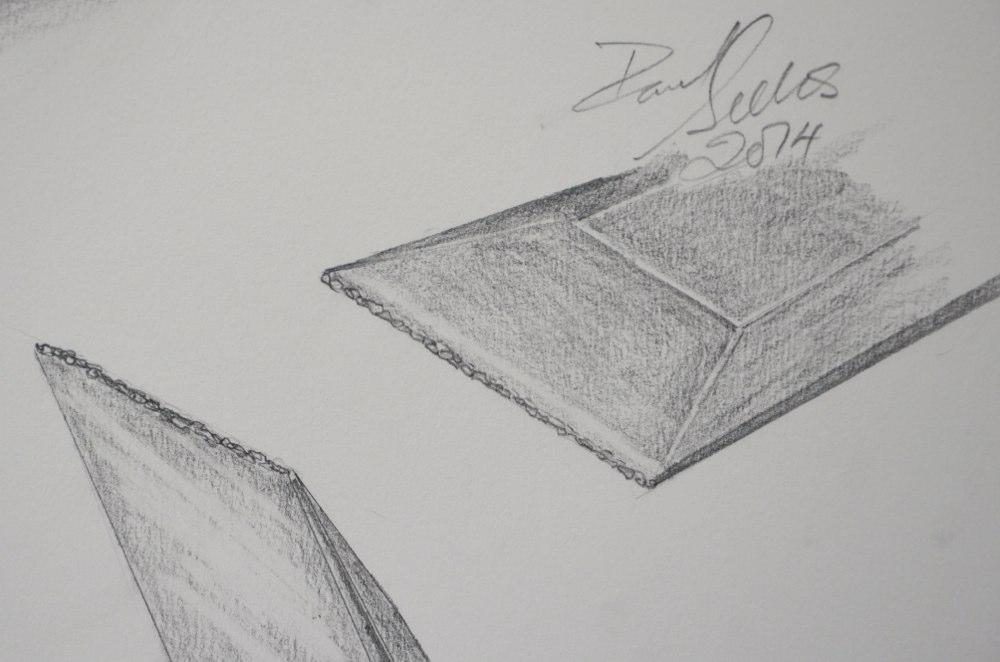

We have survived the different gospels of scary sharp and micro-bevel methodology and are emerging to this very simple reality. As long as you start the cutting edge somewhere around 30-degrees and polish it out it will cut well. If you you sharpen to around 1200-grit it will cut most anything you need in woodworking. If you sharpen to a polished edge of around 15,000-grit you can slice the most delicate of materials effortlessly, but 98% of the time that's far from necessary. What am I saying? I'm saying that we generally sharpen to task but often sharpen to a higher level because it's not much extra effort. We all know after a few efforts at sharpening that the greatest effort comes at the start of the process when we have to regain ground to get through a fractured and dulled edge and back to a productive cutting edge. That said, it's not a big deal, just a few extra strokes on the coarse diamonds gets you there. So, if that is the case, why do we sharpen to higher levels than are usually needed. Well, it is a fact that the more polished the two plains forming the arête for a cutting edge are, the sharper the edge is but the stronger the edge is too. As I said, the extra effort is worth the work because it's so quick and effective. It's not so much what we do to the edge to establish it but what we do to the edge after we have prepared it for work. Taking the chisel to the surface of the wood to work the wood begins an immediate process of edge reduction we now know is edge fracture but was once called wear. No matter the steel, edge fracture occurs at some level but some steels fracture more readily than others. What we often do not realise is that it is impossible to find a steel that both takes and retains an edge and at the same time has a level of durability we can rely on forever. All edges wear away by fracture and constantly need restoring. Not without getting into samurai sword making for ordinary work will find an edge retaining steel built to last more than a few hours. In the everyday of life, as a woodworker, we must understand that as soon as the chisel or plane is presented to the wood, edge fracture occurs to some degree. At first the edge fracture comprises usually small amounts of break out and breakdown. That is, in fractions of a second, within the first strokes and chops and pares in the wood, the edge we perfected has now been reduced. Surgery is no longer possible. But, in reality at the bench, we actually rely more on this edge-fractured edge to give us an actual working edge than we do or can the sharpest edge. The opening fracture is very small. Tiny. It is none biased in that it comes from the 30-degree corner we formed not the two facets as such. The facets are both strong and supported but not so the edge itself. The edges always fracture and guess what? It doesn't really matter. In fact, in the imperfect world of sharpening we might want that to happen. In the imperfect world of sharpening we might even want the softer steels of O1. O1 has good edge retention, strength and durability rolled into one steel type. In the imperfect world of sharpening we can indeed rely on this one thing happening. Edge fracture does in fact give us the most practical working edge for most of our work. That said, continuing edge fracture results in a dull or what we used to call a 'thick edge and we must constantly refresh the edge to continue our work. This week I did some tests on different steels old and new. It's not at all scientific but the results did show that we do in fact compensate for edge fracture in the day to day of real work. Part II in this will be out tomorrow, to give you time to digest, so we can look at some of what we found.

Comments ()