Busy Past, Busy Future Too!

Yesterday a friend, Fred Sutton who is a craftsman from my home county as a child, dropped in and gave us almost 100 chisels that need new handles turning. A good two hours work! Bevel edged and firmer chisels, some mortise and other styles. I will need to do some turning now. There are other tools too, a nice wooden jack, a Mathieson, and an old Tenon saw by Robert Sorby with 10 tpi and is sharpened to a crosscut, which I think we’ll keep as a crosscut. More restoration work but everyone benefits. John claimed one of the 3/16” Marples mortise chisel and he needs a handle for that one too.

We are about done with the Shaker Deacon’s bench seat and so we are going to release the new series on picture frame making using methods unknown in the last 150 years or so. I mentioned them recently. We'll use scratch stocks and moulding planes and other methods too. I am so glad we have been able to transition dome of the teaching to video because it saves so much of my writing time. Today we have been working through a series on replicating a table following methods we are unlocking by dismantling the past in the piece itself piece by piece.

It’s been amazing to discover a piece made 150 years ago where every facet is dead square and every leg is identically sized within the smallest fraction of a millimetre. How did they do it? They did it with wooden jack planes and smoothing planes in a few strokes. I so enjoyed starting the filming of this series this week. Today we concluded much of the series and then we get ready for our fall series workshops which include the Craftsman Style Rocking Chair, an introductory Women’s woodworking workshop, Discovering Woodworking and a couple of Foundational Course. Please check online for dates and space availability.

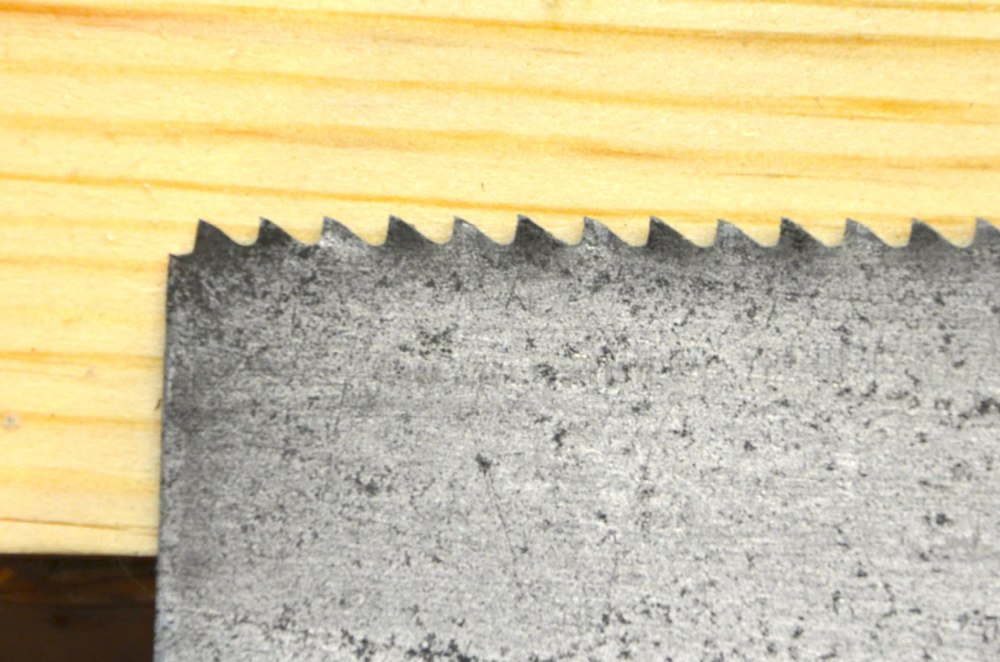

A lot of what we do in woodworking masterclasses is very unique to us. I am glad for this because that’s what is making our training so unique and refreshing to do. I often think that you might think everything I teach is old stuff I learned as an apprentice and whereas there is a lot in that, much of what we are teaching is new and innovative too. We might take a 100 year old tenon saw and file off all the teeth. We have a brand new video we just worked on that shows how you, not just me, can remove the teeth of any traditional hand or tenon saw that has bad or wrongly sized teeth - and I mean file off every single one of them - and recut and file them sharp in only a few minutes.

The results are stunning and all you need is two or three small and inexpensive tools to do it. So looking forward to sharing this with everyone. Look out everyone with woodworking masterclasses for another new and free video you’ve never seen before. It was a blast to see this come together.

Comments ()