Cheapo Planes and Saws - Are They Worth Effort?

Question:

Hello Paul,

I have noticed a number of shops selling hand planes for ridiculous prices. Machine Mart has own brand Clark's on offer for less than £20 for a no5 and less than £12 for a no4. Would you ever consider trying one of these low price planes and seeing if you can get it to sing like one of your old Stanley or Sorby planes? I guess with some tinkering they may be adequate.

On another note, I have quite a collection of plastic handled saws that I have been collecting of various makes and types. Would you ever consider manufacturing your own replacement handles for these? Would it matter if the teeth are hardened? Could I file them off and start from scratch?

I'm currently attempting to make your workbench using some old 3"x9" timbers we reclaimed from an old cowshed in Dumfries. I'm trying to do it all by hand and resisting the urge to stick it through the table saw. I'm just finishing up on the first length and have burnt a few calories I can tell you!

Thanks for being an inspiration and keep up the great work.

Kind regards

Stef in Hull.

Answer Q1: Are import planes worth tinkering with for good results?

I have done that with these low-grade import planes, Groz, Anant and unnamed makers (I like a challenge), and you can almost always get them working to some measure. The problem isn’t getting them to work initially, it’s getting them to be worth your time investment. Poor castings and machining, poorly hardened cutting irons, often warped, mean the parts are often too loose, unfit for purpose and therefore unsuitable for long term use. I am sure that they could establish higher quality in their products but companies like Clark, Harbor Freight and many others bring in low grade equipment for people who might need a tool to do only minimal work rather than high-demand tools for the trade. This is of course false economy that then puts them at less than an eBay Stanley or even in the similar price bracket to a good old Stanley or Record, so I feel you would do better about simply buying one via eBay. More modern Stanley and Record planes are deteriorated models compared to the early ones, but even these are better than the import models described.

Answer Q2: Are plastic handled saws worth replacing the handles on?

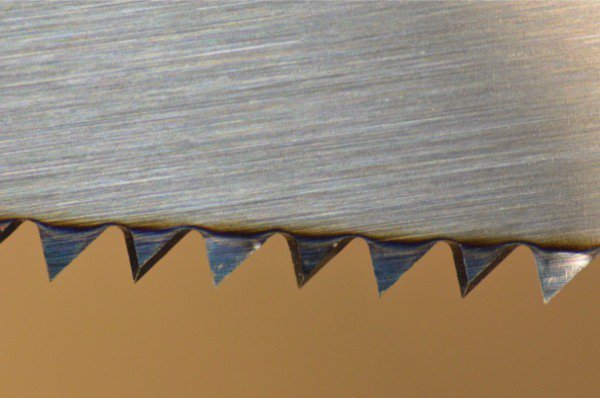

Plastic handled saws can be rehandled of course but making a handle of any quality is a lot of work and indeed that’s a lot of work when you still end up with a saw that you cannot resharpen. As for filing off the teeth. These teeth will not file so you must grind or snap them off. Snapping is faster. Running the file across the top of these teeth will immediately ruin the file and a couple of strokes. That then is the cost of a file. Again, this makes the whole process questionably prohibitive. Usually the steel is too hard throughout the saw plate too and so cannot sharpened with a regular saw file. The whole process at this stage would make it very expensive. Considering that there are good saws worth the effort of restoration to be had elsewhere and on eBay, this then becomes the best option.

There are a few old plastic handles from the pre-hardened era like this old Sandvik from the 1960-70s era. I used one of these for 40 years and still have it. I own a couple I have picked up and plan to put wooden handles on them. They were made from good swedish steel.

Answer Q3: Using machines - Do they have their place?

This wasn't really posed as a question but offered more as a workout instead of the gym. But the question for me is am I cheating if I use a machine. My answer is that it depends on many factors not the least of which is whether your goal is to develop the substantive skills or substitute for it. Everything I do is to resolve the desire in people to become truly competent in their use of hand tools and to discover just how valuable they really are.

I have no problem using machines and indeed anyone else using machines. Much of what I do is to show how non-essential they are if you don’t have them. Remember that 95% of British woodworkers do not have power equipment nor the space to keep it and use it. I found that in the US on the other hand, people had massive space and land even to build a dedicated machine shop for woodworking. When I asked a class of 20 students in the US who had a machine set up with five or more key machines, 80% raised their hand. In the UK when I do the same almost every time no hands go up.

So, if you live in the Bronx in NY you are likely to want a workbench and hand tools in an apartment building. These issues define real woodworkers but also separate out the two distinctly separate areas of woodworking which are machining wood and working wood by hand. there is no similarity between the two.

Machines for me are useful for doing much dimensioning work. I use them for that. Though people feel I am anti machine, I have never said we shouldn’t use them. I just teach what’s missing from woodworking today.

Thanks for these questions. I am sure others have the same questions and so I hope that this answers their questions too.

Comments ()