Questions Answered - Cross Cut and Ripcut Saws

Question:

Hi Paul,

I am trying to understand the difference between ripcut and cross cut saws. It seems confusing to me because there are so many. Do I need one of each or just one. I think from reading your posts and watching the video on saw sharpening you are saying I need only one. Is that the case or am I missing something?

Answer:

Here is the long answer. I understand the confusion you and most others new and not new to woodworking with hand tools find in trying to understand which saws to get. Here are some of the reasons I see that cause evermore confusion. First off if you look in any tool supply catalogue you will see the same saws with different names on them that look the same and yet have crosscut and ripcut as part of the description and then you also find different numbers of teeth per inch of saw length ranging generally from as few as 6 teeth to the inch and as many as say 32. Add into the equation pull stroke and push stroke and pull-push hybrids and the confusion only gets worse. Beyond that you then have articles in mags and online coming from unverified sources adding in their two-cents worth and before you know it you abandon the quest because, well, it’s so unclear as to which one, two or three to choose.

Let’s face it, a tool maker or supplier will always want to sell two or three saws to a buyer and the simplest way to do that is persuade you the buyer that you need both crosscut and ripcut in every size of saw made. They will also give the impression you need every saw length made, which will total a dozen or more. Of course a saw arriving sharp saves you having to know how to sharpen and clean one you might buy on eBay or secondhand and there are good arguments in there too. Which new woodworker wants to or has the fore knowledge to start sharpening their saws? It can indeed be a dilemma.

Pull Stroke Push Stroke is a Push-me-pull-you

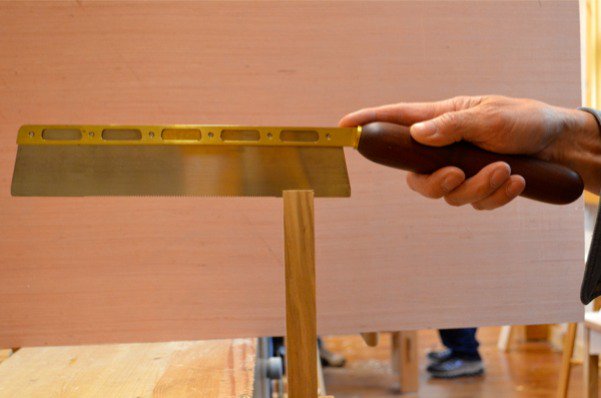

First of all let me tell you that it’s the Japanese that used pull stroke saws and it’s catalog companies that imported them and did a marketing job to make them accepted in the western woodworking culture. I think it was successful. What the western culture of sales needed was a shot of competition to shake it out of its post war lethargy. Because western saw makers were putting out low quality products and lived off their parent’s reputation, we in the west saw the saw making demise take saw making out of our culture for a season and it wasn’t too hard for Japanese outlets to sell their pull-stroke saws. Thankfully this led to an independent man starting a saw making company to develop the Independence Saw. A dovetail saw with high grade plate, beautiful handle and a milled brass back. He set the standard. Others came along too. The Wenzloff saw set the highest bar of all in terms of finish to the handle and overall appearance. Were I to choose a saw or series of saws I would pick these I think. Then again I love what Glenn Drake came up with in his innovative saw design which is the easiest start saw and alignment to cut I ever used.

The fact is that neither the Western or the Eastern saw worked better one over the other. many will say I am wrong but some of the very finest work ever accomplished was done so with western push-stroke saws. Japanese saws are just different. The problem arose when saw makers and sellers saw a niche where they could sell the Japanese pull-stroke saws to a western market buyer. Makers as always wanted a disposable consumable and so added impulse-hardened teeth, which yet again put them in control and meant buying into the disposable saw. There were two main reasons for this. Most people, 99% of woodworkers, would not have the developed skill or knowledge to sharpen Japanese saws and people are looking for something simple. Throw away is simple. Wrong, but, in the short term of false economy, simple. Japanese pull stroke saws are different and some are quite complex with additional bevels. Impulse hardened teeth last many times longer in sharpness than regular hardened steel that is resharpenable. This resulted in successfully converting people to a culture resulting in disposable or throwaway saws that lasted a few months instead of decades and even centuries. The reality is that western saws have the same ‘success’ story of supposed ‘progress’. They too make throwaway saws and this is what predominantly sells. Straight off the bat I would advise anyone not to buy or buy into the disposable saw lie. I would also advise that Japanese saws are not necessarily better or worse than western saws. I have used both types extensively. I want a saw I can sharpen over and over a thousand times and more. I want one that takes me only 4 minutes to sharpen and one that cuts to the line every time I pick it up. I think that the majority of pull saws made by mass makers have hard-point teeth. They cannot be resharpened with conventional Japanese saw files. That said, there are reputable suppliers selling resharpenable pull stroke saws. These saws are honestly produced and stand in the face of those produced as counterfeits by other mass makers.

If you prefer a ready-to-go saw consider starting with a Veritas or two new saws

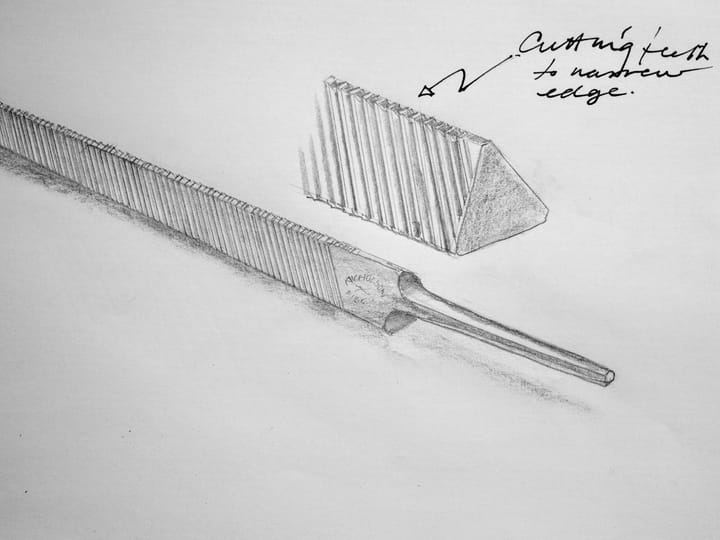

I wish that we could return companies like Henry Disston and Nicholson Files to their native countries and domestic standards instead of feeling global supplies are good progress. It’s a terrible thing we are doing globally, destroying countries, economies and people’s lives with our demand for cheapness. If manufacturers would listen to us we would have improved products made for a lifetime of daily use. Today’s term 'progress' is highly questionable.

As with most hand tools, you will rarely find that one size fits all. I own dozens of saws of every type, but use only three or four. I buy them cheaply second hand and restore them to former glory. That’s how I became a master saw doctor. That said, you can sharpen any saw to rip and crosscut using the same saw. Eventually you may want to define one saw with more a fleam-bevelled pinnacle cut. Shortly we will be completing the video for this method of sharpening. Follow my progressive rip video to see how best to sharpen a saw that will cut both ripcut and crosscut and give you an easy-start saw.

Comments ()