Another Week Seems Filled and Developed

Finishing Your Projects Following Mine

There is no doubt in my mind, woodworkers love working with wood, using hand tools and even like to use machines for some of the time. What they do not seem to like too much from what I have learned is no surprise to me. They do not generally like finishing their work. Why is that? Well, I always ask woodworkers what they feel is the most difficult challenge they face in their woodworking. This is my conclusion. In almost all cases they feel inadequate to the task. With so many finish choices available they feel confused as to which finish will work best and therefore inadequate to choose the right finish. With such limited experience and so many different products sold for finishing. Again intimidation seems to them a high risk possibility of failure in that they might fail their project by making the wrong choices or applying the finish with little experience and unskilled hands.

Two Finishes - Simple and Effective

We are working on a series of finishing videos to help minimise failure and take out the possibility of risk and so show simple techniques that minimise risks associated with being a winner at the finish line. This week we concluded filming using two finishes and some techniques on finishing for our upcoming woodworking masterclasses online broadcast. When we made the workbench stools (that are the same as bar stools but ultra hand made and ultra comfortable too) series a few weeks ago we said that we would do this and the stools are ideal pieces for developing skills. Here are the results of this weeks videos. I am happy with the way they turned out and my hope is that finishing and trying techniques will be less intimidating for everyone. I ordered my milk paint from The Old Fashioned Milk paint Company, a long-standing company with masses of experience in this unique and wonderful finish. The second finish I chose is Danish oil. This transparent finish is quick and simple and really a good finish for things like chairs and stools. See for yourself how these two finishes came out.

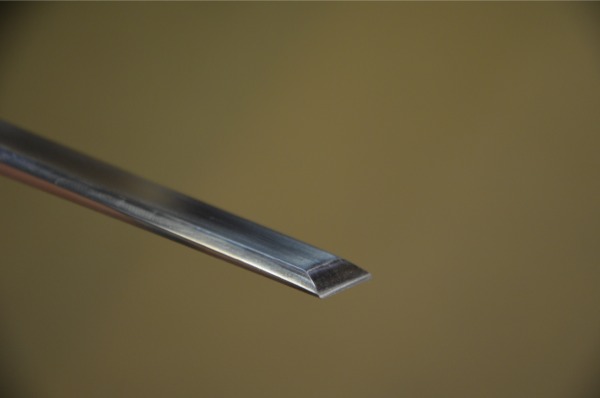

I acquired more tenon saws on eBay and was surprised at the quality I got. Reworking them was interesting and the outcome my reward. It is still amazing what you can get for under £20. John purchased a very nice I Sorby 1 1/4” bevel-edged chisel he has wanted for some time and will be doing the restoration over the next few days. We have been looking at chisels in greater depth too, as you might tell from some of my recent blogs. I am revamping the Aldi chisels and have decided to see just what it takes to make them top notch for under £3 each including the price of the chisel. I have more yet to offer but I think that you will be surprised with the outcome. Separating the chisel blade from the handle is simpler than I thought even though the two parts are very solidly united with a twist free and unbreakable grip to the handle. The tang is not tapered or traditionally shaped or made in any way. It is substantive though. It’s indeed unusual in that the octagonal tang fits into a carefully sized hole that compresses under the pressure of the hard corners of the tang’s hexagon. That tang was solidly embedded. It took a shift and hammer blows to drive the shaft from the tang.

I worked on this one 3/4” blade, flattened the flat side, refined the bevel and of course shaped the bevel with its refined convex bevel. I like the bevel’s size, not too thin at the edge of the bevel, nicely tapered and enough steel to give me confidence. We’ll show you progress as we go.

Comments ()