Plane Retrofits Improve Design and Comfort

A couple of years ago I noticed that two of the Veritas planes have fence or and depth stop slip because I can’t apply enough thumb and finger pressure to cinch the knurled mechanisms tight to the shaft/s. My hands and fingers are extremely strong and the problem wasn’t me so much as a design issue. I approached veritas with what I encountered and see that the problem still exists in the router plane and the small plow plane they manufacture. I can’t risk fence and depth slippage in either tool and had hoped the problems could be reconciled. I thought it might help if I showed you what I did.

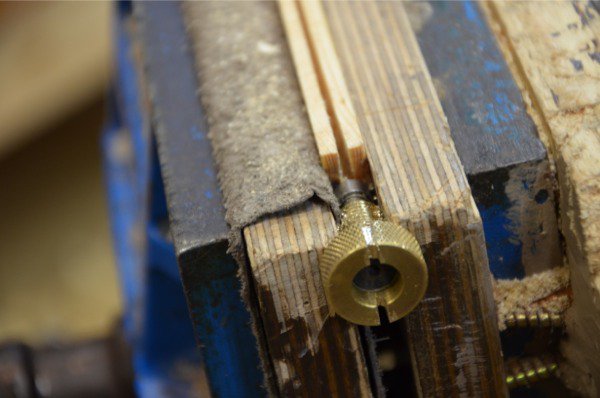

My suggestion in the past was some type of grip to fit over the clamp screw that would enable a tighter grip. I can’t manufacture that but innovators could. Instead I cut a channel across the end of the securing lock nut about 3mm deep. You can see I used a channeled piece of wood to guide the saw squarely across the end so that it didn’t skip around. Then I cut two channels into the walls of nut either side of the centre using the same hacksaw. The kerf is two blade kerfs wide. The side channels guide the key in and the channel across the end that connects the two channels is where I can apply more solid pressure. I used a 3-square file to relieve the edges. This channel matches the thickness of some brass plate I had. In the brass plate I used to make the key I removed a section from the center of the plate to match the brass tightener and shaped the end. Turning this turnscrew even mildly ensures the security of the assembly perfectly and resolves the design flaw.

Stanley too has a minor flaw in that on their #4 planes they have no set screw to the fore part of the tote. This means that the tote can slip and the screw often loosens as a result. I add a piece of silicone shelf liner between the tote and the cast iron sole, which totally resolves the screw from coming loose

.

Comments ()