Questions answered - Don't let finishing stump you

On finishing a project

Brian wrote to us on woodworkingmasterclasses this week and strangely enough, while I was finishing off the recent tool chest project I was thinking about how woodworkers are intimidated by finishing. I think that his letter reflects the feelings many people have and you can read it for your self:

Hi guys.

Wondering if you can answer a question.

Finishing really has me stumped. Scares me to death.

I am just finishing a pair of walnut shaker night stands and soon it'll be time to prepare for final sanding and finishing.

My first question is is it necessary to sand "back" to 240? I have glass smooth surfaces after final smooth and now I have to remove that perfect looking finish? It almost hurts to put sandpaper to it.

Second question is does finishing HAVE to be as complicated as magazines and manufacturers make it seem? Paul, did craftsman really jump thru 15 hoops to finish a nice piece of furniture 50 years ago?

Thanks for everything. I love the masterclasses too!

Brian.

Answer 1:

In my view the answer is yes you should sand down or “back” to about 240-grit before applying finish. Try to think of the wood and the finish as two separate surfaces and indeed items. Some finishes such as oils are indeed soaked into the surface of the wood and penetrate deeply. Some oils for instance. Many so called oils are little more than oil-based finishes with other additives added that skin the surfaces of the wood and many of these oil-based finishes will have added polyurethane for instance which forms the skin I speak of. What many woodworkers refer to as a hand rubbed finish is nothing more than say Danish oil applied with a rag in successive coats, wiped off after a few minutes and allowed then to dry between coats. Nothing wrong with that in itself, but they try to suggest that this”hand-rubbed finnish” is comparable to French polishing which is indeed a had rubbed finish, but French polishing is an art and craft in and of itself and takes much skill to master whereas applying oil is dead simple and takes no skill.

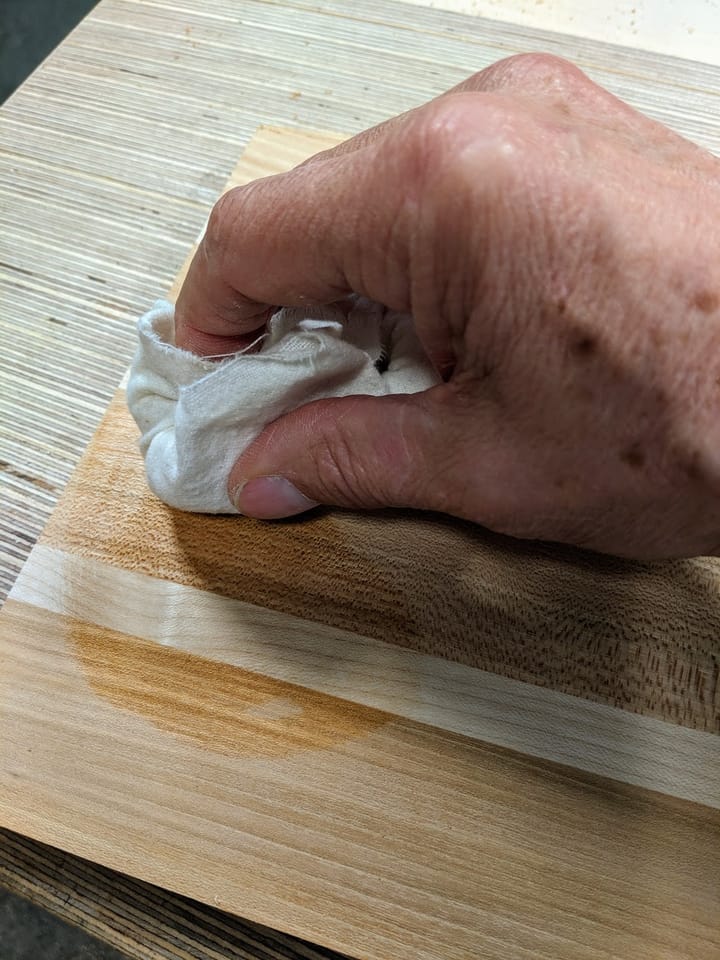

I suggest that you apply Danish. Not all Danish oils are the same in that they have different chemistry and content. In the USA I like Deft wood finishes. Deft Danish oil is a high quality oil that works well on just about anything and I used it for two decades when I lived there with no problems ever. I like the fact that you still feel you are touching the wood after you have built up four or five coats. Apply it with a rag, leave it for 20 minutes and then vigorously wipe it off as though you are trying to remove every trace of residue. It can be hard work if the weather is warm, but it is worth it. The rags when wadded up and left untreated can spontaneously combust so take care to discard them safely. A can of water for total immersion works best.

Back to my answer: Sanding the wood gives ‘tooth’ to the surface and it’s this tooth that most finishes grab on too. Many finishes shrink and stretch as they dry, pulling themselves to a taught skin on ‘op’ of the wood. When the surface is to slick, the finish has less to attach itself to. Oils do better than varnishes but as most oil-based finishes will state that they are oils and not oil based, two different things, you may find that you are applying more of a wipe on polyurethane than you are actual oil. Tooth is important and that’s why we rarely sand beyond 250-grit because finer surfaces tend to give poorer adhesion.

Building up sufficient coats means that you apply enough initial coating to sand down without sanding through the initial coats. I usually apply a coat of clear bleached shellac first, which can be used with most top coats (This is not necessary with Danish oil). This is usually the only sanding I do but I am never likely to go for a super high gloss finish as I don;t like the plastic look-through look. There are some excellent water-based high glossy finishes used for guitars that are stunning if that’s what you are looking for. These are best applied with an HVLP sprayer and then sanded out after the coats are built up. Not usually suited to furniture.

As a final point on sanding; try not to round over the detail to end up looking like an American 2x4. Use a padded block if necessary to prevent this.

Answer 2:

There is no doubt that magazines provide content that rarely ever simplifies the issues surrounding woodworking. They are mostly advertising billboards for the giants of the industry and the more then can have you coming back for a dangles carrot the more magazines they sell. Most magazines sell magazines surrounding key areas of concern to woodworkers for the very thing they know woodworkers struggle with the most such as sharpening tools and applying finishes. Just as sharpening is as simple as abrasive, angle and steel, fishing is sanding, build-up and drying.

Conclusion:

I would go for the Danish oil. It looks good, feels good and is easy to repair and recoat in the years to come. Walnut in and of itself has wonderful colour that needs no further colour adding so coating is dead simple. You cannot go wrong with Danish oil. Later, you may want to investigate other finishes and methods too. We are working on a video to that end on woodworkingmasterclasses. Also, I am just finishing up my tool chest with shellac, you might want to watch that too, before you start.

Comments ()