Questions answered - more on benches and heights

Here is an email I received and it's not the first but one of many along similar lines. I think I have answered them in past blogs but less specifically and so I thought that this blog might help other to understand what I feel about benches and heights and where I might rest my thoughts.

Hi Paul,

I just had a few quick questions regarding your noble quest to find the right bench height.

-Is your favorite 38" inch high bench design (the one you made an instructional video series about) based on a workstyle that uses mostly pre-sqaured stock?

You seem to work around brutal planing in your videos by using lubricant and a nimble, well tuned plane. Ingenious really.

-Do you ever use a jointer? You also seem to have an excellent face vise to be able to do things like hand-mortise in it.

In your blog entries you seem to say that the roughest work of stock has been relegated to machines, and so benches need not be so massive and low. The hand-tool woodworking gurus we generally bow to in the U.S. (Roy Underhill, Chris Schwarz, Peter Follansbee, and so on) advocate the use of low benches to enable the processing of rough stock by hand. This obviously comes at the cost of the back when it's time to dovetail something, but seems to be necessary. It's hard work doing getting enough oomph into the work with my 33 inch bench as it is! Anyway thank you for challenging the status quo the way you do! You offer a refreshing and enormously helpful perspective.

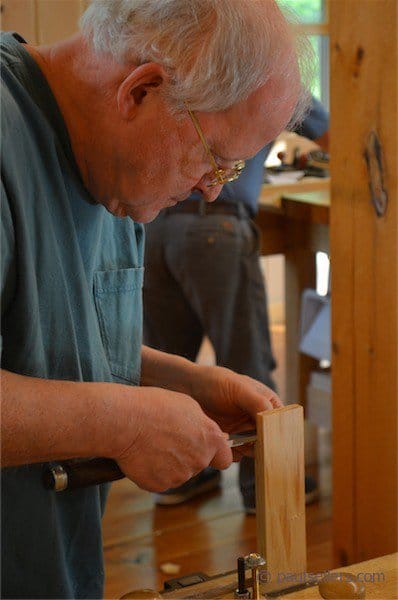

My personal experience with benches, working at them and building many dozens of them spans 50 years. This work has been daily working six days a week and mostly 10-12 hours a day on average. Since the days of my apprenticeship I have never heard of anyone else who has done this, but I know they are there. I suppose my perspective has a little substance because I have been standing within six inches of a bench corner and its vise for that length of time.

I worry at how quickly we look to others for expertise, mostly because they hold special positions and are in some measure gifted speakers, writers, presenters and so on. People question me on many issues avery day and I respect them for it. A background researching old books, making films, even making benches doesn't always qualify us to advise people. I am careful with my answers because they have long term effects on others. I think most of those giving advice generally care that they offer quality advice too. So here are my own thoughts for what they are worth.

I think that benches were lower for many reasons not the least of which is lifting large frames, chests of drawers, boxes and such during construction to work on on top of the bench. This raises the work height for subsequent tasks such as planing and sawing on the the project, inlaying it, trimming it out and carving it; all good reasons for a lower bench to work at. The vise too is used for more than just joinery. When you plane a frame's edge it can be positioned to almost any height in the vise. With a sharp, well-adjusted plane, you need only minimal downward pressure but accurate forward thrust. This is so for planing square stock and board edges. You can move these items in the vise to suit you and your personal comfort-height at ranges infinitely variable. You see, if you give the impression that the majority of woodworking is planing rough stock smooth and flat it affects your opinion. Most woodworkers don't do this very often if at all, so the reasoning that lower benches meets the needs of woodworkers today could be more outdated or even archaic than reality. On the other hand, let's look at the height of men in the 17-1800s, or even only a century ago. It does seem that the average height for males is now 4" taller than 100 years ago. The average European and American male is 5'10" or thereabouts. A man 4" shorter would feel comfortable at 34". It makes sense then to assume that shorter men needed lower working heights so a typical male working at 34" would likely feel what we average men of 5'10' feel today. If a man were six foot plus I would question the long term impact on his back and neck. It's interesting to see the hundreds of emails from people who shifted from 34" bench heights and lower to 38" in the last few months. There's a lot more to this than we think and I am so glad my bench height matches my back, neck and eyes.I suppose we should all at least consider where, when and whether we should think for ourselves and question what's behind the authority and especially so if it directly affects our personal wellbeing or those we are involved with.

Yes, I do like to use jointer planes and even jointer machines too. I like them for certain work, but what I like also is to give people what will work on a limited budget and space. I know this all too well. Craftsmen of a hundred years ago didn't have the luxury of stowing long planes. They had a functionality and purpose and so they had them as I do to work on different bench tasks. I advise woodworkers to buy all the range as they need them and not to feel that they are inadequate to task if the don't have them all at once. It's fun acquiring your tools over a number of years, especially with eBay and other secondhand venues.

Comments ()