Shaping and rounding the spoon

Shaping in the round

There’s a sense of apprehension sometimes about shaping the wood and especially when you carved a perfect bowl. This is what we call the risk of work. In general, machines are designed to substitute for workers developing skill. Skilled workers in the past ended up in the factories of the western world to become part of the mechanism of the Industrial Revolution. Redesigning product manufacture for machine production brought predictability to the work place in the same way engineered boards meant predictability for IKEA, Walmart, Asda and other big box companies. Using machines took out the risk of making normally associated with craftsmanship and took away the heart of craftwork. Dumbing down skill of course meant cheap goods to satisfy demand for the insatiable consumerism that feeds economies like ours, it was of course the only way to guarantee profits through and for mass manufactories. The way of the crafting artisan on the other hand knows no such bounds; he and she must live and work inside their materials so that nothing intimidates them and they come to understand their material thoroughly and then some.

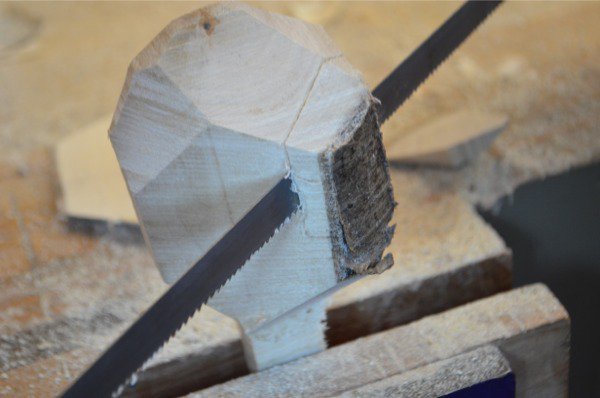

Once the outline shape of the spoon is established and cut, further shaping begins by removing the bulk of the waste. This can be done by sawing, chiseling or axing. You can also remove material with a spokeshave but this takes much longer. We will use the spokeshave for refining the work of the other tools. That’s what they do best.

The spokeshave is the first tool I ever bought for my boys. It’s simple and effective to use and it lives very close to hand on my workbench. The spokeshave is basically a plane with side handles. Two types are available; bevel-up and bevel-down blades. Today, the most commonly used are the bevel-down versions we know as the 151 originally made by Stanley but now made by others too. There’s not much to go wrong with the 151. Keep it sharp and it will perform almost any task in the round as it were.

Removing the waste is quick using the bow saw and the bow saw brings a predictability to the shaping without too much practice. Axe splitting too removes material quickly, but you must develop accuracy and skill. This of course takes a little practice and don’t be put off by the thought. I think it’s important to develop the ability to read the grain and so better understand where each cut must be placed. Using a chisel and mallet will remove material effectively too, but you must understand grain orientation to guarantee a good outcome.

Of all the tools used I think that the spokeshave works wonderfully for shaping and rounding the handle and refining the back curves of the spoon. With careful direction choice the spokeshave leaves a lovely texture to the surface of the wood and is an acceptable surface finish.

I recently tested out the Auriou rasps and really loved using them. They are risk free and they remove material quickly.

Beyond the spokeshave I often use the card scraper to refine the work of the spokeshave. This leaves a smooth surface and removes any and all undulation left by the other tools. I use thin plate card scrapers because I can flex them to the surface and get a continuous finish.It’s a matter of personal choice how much you want the spoon to be finished, whether you sand the surfaces or leave the tool marks as part of the texture.

Comments ()