Jury still out on bench heights

From the populous comes more and more information leading to better understanding and greater levels of actual reality. Now that we have passed the 100 mark I would like to press anyone who didnt submit their details to help us with the survey toward better understanding of bench heights to help your fellow woodworkers and send in your information too. Please follow the guidelines below:

It seems that 98% of woodworkers do not use and will never use wooden bench planes for working wood but if they had them they might play around with them for a while. That may be a little sad because they are likely to never fully plump the depths of how brilliantly they work. From a practical point of view, statistically, they shouldn't really affect the survey because people in general are NOT using them for their real work.

There seems something of a correlation between height for seeing and sawing vertical cuts as in joint making as opposed to overhand ripping or crosscutting lengthS of stock, which usually has little to do with workbenches per se but more to do with using saw horses. Quite distinctly separate aspects of woodworking. Short stock is easily cut in the vise held vertically and shifted up in the vise to expose more stock as you cut. Crosscut ting planed and squared stock of smaller sizing is easily done this way too, or with a bench hook if you prefer.

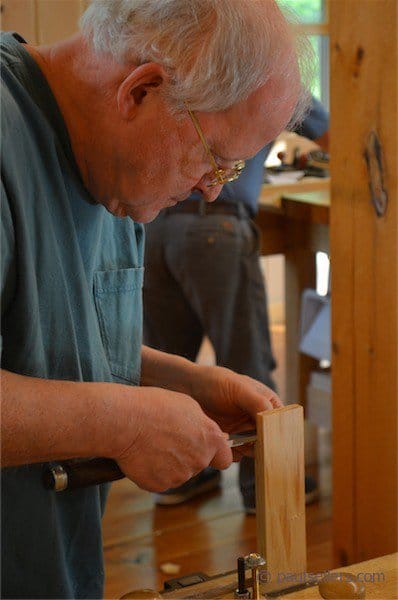

I have been asking students in the workshops about bench heights too. Not just now but over a number of years. It does seem that many factors affect our successfully establishing a good bench height to work at not the least of which is back work. Our backs seem often to be out of kilter. I rarely meet anyone who doesn't have some issue with their back be that great or small. Most Americans are very used to sitting at their work too, that translates into being very near to their work. If you are used to this then you feel more comfortable being nearer to task.this confinement if you will somewhat restricts us however because much of our work is a quick interaction between close and arms length. Swing and planing are indeed good examples. It seems many advocates and teachers govern much of their advice according to what they are exposed to and not what people actually do. Going back into history doesn't altogether help us here at all because we've changed and many processes once attributed to bench joiners are now done by machine and that makes great sense. Even hand tool afficionados use different machines to downsize stock into workpiecese for continued conversion and joinery at the bench. In all of this, saw horses make great sense, so there're is only one area that seems to be somewhat in contention and that's the act and art of planing. That being so, and some say they gain added strength for overhand, overhead planing, how much actual work do we do this way or should I say does one do this way?

As I have said, I have worked from bench heights between 36-38" high most of my woodworking life and I have made everything from many dozens of workbenches to dining tables, coffee tables, conference tables and every conceivable cabinet you can imagine. I have also taught 4,500students at my benches which are almost all 38" but we have a couple additional heights or adjustments for taller students. In general, students between 5'4 and 5'11" seem ver comfortable at the 38" height and rerely do we need to make any adjustments.

Another factor I think to be important for many is age related. As we grow older and agility for many becomes less than we'd like we tend to bring things to a more comfortable position. For instance, having worked a lot with children and young adultsi notice how readily they resort to working on their knees, bending over and suspending themselves on bent legs to perform a task. Of course this is temporary but none the less tiring of folder people. Older people therefore want to bring the work closer to the eyes and to less stressful positions around the upper body that performs more of the tasks they will be performing.

An issue I have encountered is that we are generally unwilling to change and that's extremely true of manufacturers too. It's how we establish bench heights that seems the most iffy to me and has been the case for some time. Walking into a store and looking at workbenches always disappoints me and so too catalogs. The benches offered are always too low for me and I suspect others too. I went to one of my favourite woodworking suppliers and looked up benches in the Lee Valley & Veritas catalog. All of the benches offered seemed to start at 33 3/4" and max out at 35". I should be able to say confidently that Sjoberg benches, this has been an industry leader for decades if not a century or so, have it down and are giving people what they need but with thier average bench heights of 34" I cannot do that.

I conclude that if you do buy a bench that low, be prepared to cobble on an additional block for increasing the height and don't just accept the status quo. Question bench heights. Try them out, experimant a little. It's your back, your arm length, they are your eyes and it's your brain that must feel settled. More and more I come to the conclusion that under 36" is not just a little too low for a workbench but much too low for the majority of woodworkers and I will also reiterate that there is no one-size-fits-all height workbench either.

Continued support in our survey

Once again we need your help

Here are the definitive questions we feel will help establish factual considerations. The more contributors we have engaged in this, the more accurate the evaluation.

Your physical height

Age

Gender

Occupation (Present or former)

Physical disabilities

General health (Scaled 1-5, 5 being excellent)

Current bench height

Satisfaction level (Scaled 1-5, 5 being perfect)

Country living in*

Nationality*

Other information that will help the survey determine more specific issues we might be missing.

*Optional. These questions will help us determine if there is cultural influence on height.

Comments ()