The Question of Bench Heights

This question occurs often enough for me to want to help with. When I owned a walking cane manufactory, every medical organisation took the crease in the wrist as the ideal height for all people to determine the best length to cut the cane to when the person was standing upright. This generic formula worked well for most people walking with a cane who had some physical agility, but customising the cut was the best of all. The problem was that once the cane was generically cut it could be long enough for a refit or too short for the custom fit. Physical abilities affect bench height and it may have nothing or everything to do with age, gender, dexterity, fitness and more. It’s often said that we can gauge height by knuckle-brushing and that we need ‘over-the-bench’ upper-body posturing to plane surfaces, which I find untrue in general. As a Mr-Average of 5’10 to 5’11, all my benches are 38” to the bench top. At this height I can plane and saw and chisel just about anything. My students seem to work without any problems even when they are at 5’4”. but when they exceed six foot they find it uncomfortable. We have more people over six foot in our UK classes and have two bench spaces to cater to this.

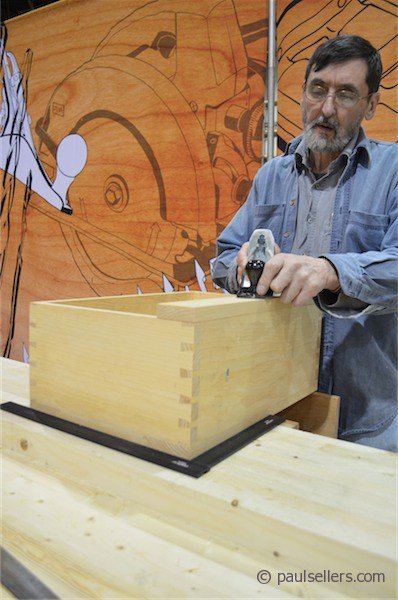

This student above and from Holland was 6'2 and liked using the 42" bench alongside a fellow student who was 6'4". Both seemed very comfortable.

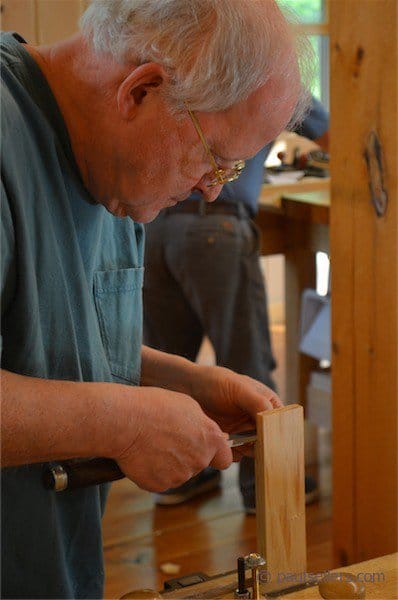

11 year old Isaac in the top photo is working at my bench in New York. He made one of the bowsaws a couple of weeks ago in an evening workshop and did it entirely on a 38" high bench.

How did I establish 38”?

Most planing is planing small components or sections of wood. Rails and stiles, box sides, lids and almost everything is fairly small even on large pieces of furniture and is best held in the vise or by the vise in some way. At 38” I find everything can be planed comfortably near to the working corner of the bench and even large tabletops can be planed perfectly across the bench too. Using the clamp-in-the vise dogging system I wrote of here means I can plane a 4’ wide tabletop 7‘ long at the most perfect height I have found and so too the students in my classes. Does this mean there’s a one size fits all? No, not really, just that you should start tall, try it for a few hours and then cut to height incrementally to match the bench to the person. If the bench is a multi-person use bench, then 38” fits the average person but may not work for shorter people. In that case simply have a floor board called a duck board to gain two inches. Ten 6’ strips of 1" x 2 1/2” screwed to three or four battens with a 1” gap makes a good shelf under the bench and can be withdrawn and used as a duck board as needed.

It's what students tell me

Through about three decades I worked at different bench heights in the shops of other people. My own bench when I was at my tallest of 5’11” was 36”. My eyesight was 20/20 and that’s still the case now two decades later. (I wear bifocal readers so that I don’t have to take my spec’s off when I demo and lecture or work in general at the bench or on the machines. The top part is non-magnified.) So getting closer to my work was not really an issue. Working at workbenches belonging to others made me realize that the benches were not so much benches for making but for assembling the components they made on machines; There is a big difference. Though they looked like workbenches, their functionality was quite different. It soon became obvious that the general woodworking workbench had been decommissioned as a maker’s bench and then commissioned in the absence of hand tool work by machinists who needed to assemble machined parts into sub-units and then final assembly for glue -up and clamping. So, with the different functions in mind, and no need for the third hand to hold work being worked firmly to the bench, low benches devolved more as hybrids until hand tools were finally ousted and machinist woodworking replaced them.

Take care not to cut too low

Some recommend benches 30-36” high, and I know that varying lower heights may well suit shorter people well, but for me, now an older man, and the more general majority, these low benches do cause great discomfort, even severe back pain, because knee-bend cannot sustain and support the upper body for prolonged periods of bending and so the pressures are transferred to the lower back and upper arms and neck to compensate. I have used 38” as a standard bench height for about 30 years. The more common complaint is too low and not too high. In fact, I have never had anyone tell me the bench was too high at 38” and students seem quite content in every operation including sawing, planing, chopping and paring, regardless of plane type, tool type or action. I do think that in the absence of anything to compare with they may be limited in judgement, but I also think they are capable of making suggestions and there has, as far as I can recall, never been occasion where someone has hinted the benches to be too high.

What do you say?

I would be interested to hear from readers who have an opinion, provided they are hand tool users in the majority of the work and not machinist woodworkers. The needs are to different for comparison and so would be of minimal value otherwise. Please give your height, age and physical restrictions if any.

NOTE:Just so you know, Paul has a newer Workbench series. If you are interested in the updated version of Paul’s workbench please click the button down below. This page links to a cutting list, tools list, FAQS and much more.

Comments ()