Minimalist woodworking - Another poor-man's beading tool

Bandsaw beaders with hook

Bandsaw blades may sometimes seem a waste of good steel and indeed as an apprentice 45-50 years ago, we used to send them away to be sharpened many times over. Today they are all discarded for meltdown and that’s fine as the steel bands themselves degrade and become weak and tend to continue breaking past a certain point of cut work. I take a blade to make cutters and scratch stock cutters and scrapers every so often. They work well for that as they are about the right thickness and hardness if you use the back edge for shaping with a file or grinder. Here is another use that requires no grinding though. In about 5 minutes I can take a section from a 5/8” x 4 PPI bandsaw blade and make another type of ‘poor man’s beading tool’ in similar form to a scratch stock and the scratch stock can be used with different sizes of bandsaw tooth if you beg disused blades from other user sources. That said, keep it simple. This one can be adjusted quickly and easily to about any size of bead you want. Here we go:

Snap off a section of bandsaw blade a couple of inches long. If you bend-snap the section it will need flattening and this is done with one steel hammer in the vise as an anvil and second hammer striking from above. I snap right on the front, vertical face of a tooth

Take a piece of wood about 3/4” x 1 1/2” x 5” long (none of these are essential sizes) and cut out a notch from the end about 1” long and 5/8” deep with a tenon saw.

Mark a centreline along the stock using the finger as a guide.

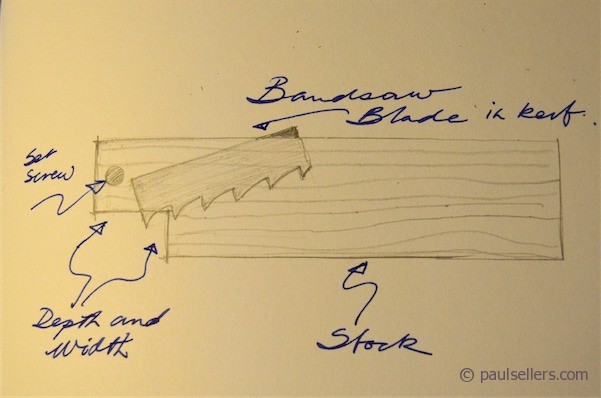

Saw down the length of the stock through from narrow face to narrow face with a tenon. I go about 3” long. If the tenon saw is thinner than the body stock of the bandsaw blade, you may need to go deeper so you can part the two sides and insert the bandsaw cutter.

Insert the bandsaw cutter into the kerf and then adjust inside the kerf to get the angle best suited for a bead shape you like.

Use a card scraper or the end of the tenon saw to adjust as necessary by inserting same into the kerf.

Drill a hole the size of the shank of a 3/4” long screw through one side of the saw kerf.

Drill a second hole smaller than the threads of the screw through the first hole and into the second half of the stock. This prevents the screw from splitting the wood so near to the end of the wood.

Screw the screw to tighten the blade within the stock.

Test the beading tool scratch stock on a scrap and adjust to size as needed. To use the tool, pull or push (or both alternately) along the wood, first passing lightly to get the exact course, and then more heavily to deepen in the cut.

Use sand paper to even out any discrepancy.

Round over the corner to complete the bead with smoothing plane or a block plane or just use coarse sandpaper to shape and sand to round as needed.

I generally run a tenon saw along the channel to complete the bead and crispen up the appearance both before and after sanding.

Here is the end result.

Comments ()