Still not done with dogs - but this is it

Though I rarely have need for bench dogs as you know them, there are needs from time to time that could be simplified if you have them. On the Paul Sellers’ bench, filling the well area in front of the vise, I introduced a laminated wooden block made from two-by stock that can stay in place or be stowed. dead simple, totally effective and low cost. Two bucks tops.

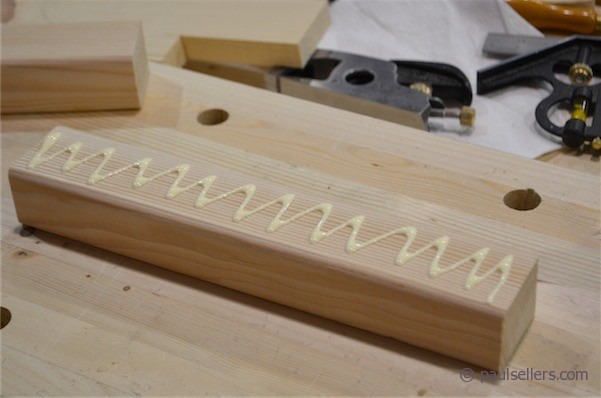

Glue-lam 8 pieces of two-by together after surface planing the wide faces of the pieces first. The pieces should ripped to the depth of the well. Also, it's best to plane down the narrow edge of the pieces to remove the round corners on the edge. Half the work of the wide faces.

Plane up the surfaces flat and true.

Lay out the holes and bore 3/4” holes to continue on from the ones you bored in the main bench top. Mine are on 4” centres.

Plane the laminated block to fit between the apron upstand and the main bench top.

On one edge, the edge that butts up against the apron board upstand, plane the edge about 1/8” out of square to give block a leading edge into the well when installing.

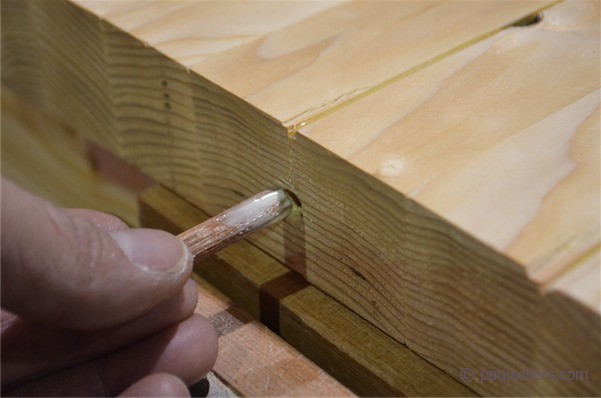

With the block fitted, drill a 3/8” dia hole in the centre of the block and equi-distant top and bottom. Depth around 1” or so. This hole houses a dowel or a metal pin that locks into the back edge of the main bench top and stops the block from rising under clamping pressure.

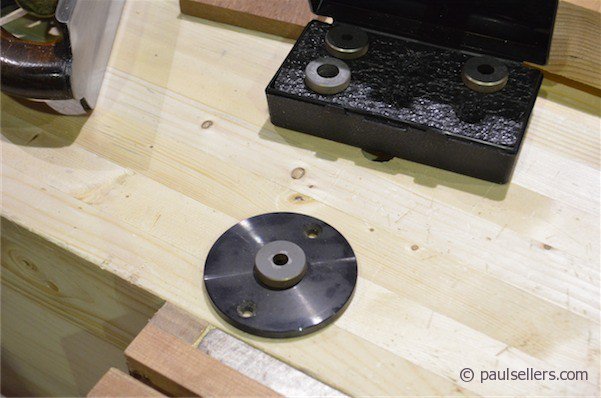

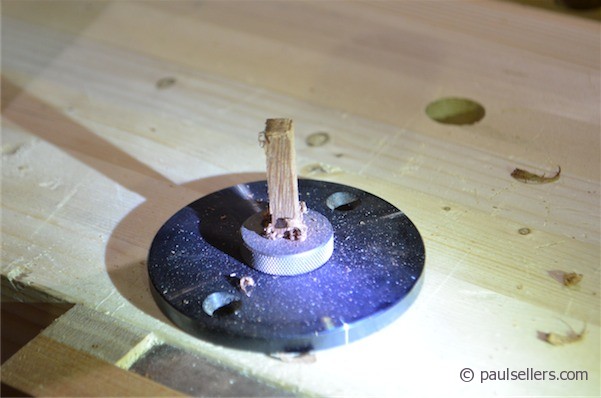

I have a Veritas peg doweller that cuts square pegs into short dowels so I made mine from some mahogany pieces I had. Worked perfectly. Any dowel will work for this. 1/4” to 3/8” is enough.

Glue the peg in place.

Bore a second hole into the back edge of the bench top.

Drop the block in place and check for alignment.I scalloped the sides of the bottom edge of the block on each side for easy lift out.

Cut new dogs from wood as described in the earlier blog. These dogs don’t require springs as the can sit right down on the hole to sit on the well board.

Comments ()