On Strops and more

Why strops? You ask. Why not stones to 25-30,000 grit?

I think that sometimes we must look beyond what magazine articles say and certainly what the catalog companies project on their pages too. Within our present age of mass-information, there exists an undercurrent that usually goes undetected yet this undercurrent carries within its sway the ability to create not clarity and singleness but mystery and confusion. I think too that we all realize that amidst the age of mass information there exists in equal measure an age of misinformation. Combining the real with the unreal or the true information with the untrue creates a severe deficit of exactly what it takes to assimilate any information at all and that is attention. We are incapable of processing all of the information that invades our woodworking turf. One thing that I know is that we are subjected to ever greater confusion the more magazines and catalogues we read. Rarely do they dispel ambiguity but create it.

Sharpening tools has become increasingly more complex. Mostly because of set ups. People are set up and here is the reason why. It doesn’t really matter what abrasion you use to create a slurry of abrasive material to cut through steel. I have used them all; from Norton India stones back in the 60-80s to Japanese water stones of every type imaginable, man-made or naturally quarried. I have used ceramic stones, diamond stones, abrasive wet-and-dry and a whole range of natural stones. Some cut fast and some cut slow. Some fracture faster than others and hollow out fast whilst others resist hollowing by any discernible amount. I cannot imagine for the life of me trying to make a decision from reading a product catalog alone and I certainly could not afford the time and money it would take to try every type. ot that mix that fact that there are a zillion unsubstantiated opinions via the internet and the whole becomes too massive a haystack to find the point in.

More and more I come across hybridized systems where people are more intent on making a name for themselves than helping dispel the confusion. In their ambition to create their own ultimate system they not only lose the simplicity of sharpening but add ever further confusion that so destroys the joy of working wood. These are the most confused methods and comprise everything from diamond paste and oil to lapping plates and wet-n-dry in twenty grades and grits. Add into that two water stones, two diamond plates and two natural stones and there will be no change fro $500. The process itself then foisted on the unknowing ones is often a two-day event to flatten, hone and polish something as simple as a chisel or plane iron. Whoa! What happened to simply sharpening a chisel.

I write my blog for one reason these days. Most of what I write is to help dispel the confusion created by magazines, but at the same time most of what I write is not the stuff of magazine articles.

The men who trained me took two minutes to sharpen and hone a chisel edge. They never used a honing guide, they got on that two wheeled bike and rode it until they found the incredible value of balance. Before long they were riding that bike like an eagle and they never came off it again. So it is with sharpening. Some take a little longer and some get t right away, but the fact is that within an hour they can do it guide-free and they too sharpen their chisel and get on with working wood.

I just want to cut through the confusion and I will not argue with anyone who wants to spend two days sharpening the perfect edge with any method they choose if that’ what their desire is. In my book, it’s best to use three abrasive plates that stay flat, cut fast and last long. A stop and a block of wood with abrasive compound creates the mirror finish I like and I am done. Most magazines come out with an article on any same subject about every six months or so. One of my editors once told me he could repeat an article on sharpening every six months without anyone noticing. He pointed out that all he needed was a different abrasive. Catalog company buyers go to the World Trade Centres in search of new wallpaper. It’s the freedom of misinformation that causes the greater confusion.

So, to answer the question, “Why strops?”

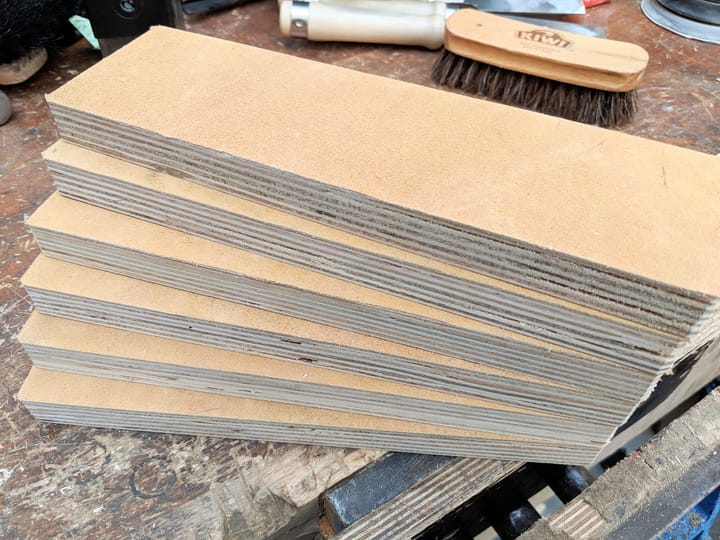

Strops are simply the most effective way of discharging fine abrasive to the bevel of any edge tool. The leather has no other equal to both discharge and cushion the cutting edge during the abrasive process at this level of fineness. The leather absorbs the abrasive into its body and at the same time absorbs all shock. There is no mess at all. Strops are safe to use, simple to make, last a long time and can be made from just scraps of thin leather and a block of any kind of wood or plywood.

Which side of the leather?

I usually use the rougher textured side for general strop work, but for ultra fine stropping of say 25,000 I use the smooth side. If the finish is too hard or smooth, I use abrasive paper to give a little ’tooth’ to the surface. I generally use buffing compound available from Lee Valley Veritas and here is the link. My strops are always 3” wide, 3/4” thick and 10” long. I used to use rubber cement or plastic laminate cement and this works well, but I found that double-sided mounting tape works just as well and double-sided carpet tape all the better.

Comments ()