Question on Workbenches - Are they Becoming Fanciful

NOTE:Just so you know, Paul has a new Workbench series. If you are interested in the updated version of Paul’s workbench please click the button down below. This page links to a cutting list, tools list, FAQS and much more.

Click here to go to the workbench page

Q:

Paul,

I think what you have written here about workbenches in general is very much so. The hype about workbench design, looks etc. is a bit over the top. In the end of the day the bench need to do what you need to get done. Meaning holding workpieces securely so that you can do the work - whatever it is: planing, sawing you name it. With the hype around benches comes the unavoidable question of which wood you have to take and I think it is very bizarre that everyone is talking hardwoods here. One feels like "2nd class woodworking" if you even mention softwoods... BUT I much prefer having a dent in my workbench instead of the dent in my project piece when I accidentally slam something against the bench... good luck with your hard maple benchtop... I suppose those thinking that way are building workbenches not to use them but to show off a beautiful piece of "workshop furniture".

Anyways, as much as I like your design (I started laminating the tops this weekend) I am curious to know your opinion about other designs like and especially the Roubo. I can generally see both benches being as functional as the other with the slight difference of a more difficult built of the Roubo. OK, it has no tool well (the reason why I chose your design) but besides this what are your thoughts?

Thanks in advance for bringing some more controversial opinion into the woodworking community Paul, which I much appreciate and like! Keep this attitude and mindset up!!!

A:

I suppose my views on workbenches have been scrutinized by many through the years. Functional benches of old are now receiving more polish and smoothness than ever and at shows and so on draw much attention if they look like a man’s dining table or a new ‘man’s den’ piece. I think some times that they are just enjoyable to make and that’s probably nearer to the truth. Eventually that wears off when the saw catches and the chisel slips. We ultimately end up with a real workbench and that's what matters.

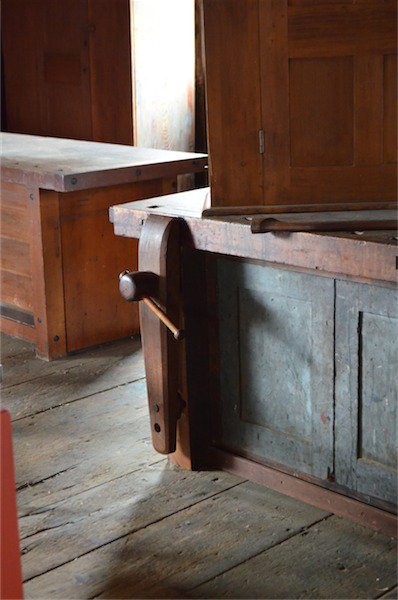

Though very low, I think that this Shaker workbench at the Hancock Shaker Museum is quite lovely to look at

Over the years there have been many changes and woodworkers of every type talk of their reliance more on bench mass that delivers sufficient weight and stability to give resistance to the many pressures of lateral push and shove, pull and twist work necessary to withstand their impact via plane work and sawing. Fact of the matter is that, in general at least, we no longer need such mass in most of our joinery and benchwork exercises because much of that bulk and mass work once necessary in the 1700’s (when Andre Roubo kept the notes surrounding his workbench) has been redirected; relegated to the machine. Massive tenons for doors and structures are most often cut on tenoners, machines that will hold a 9” x 9” oak section 10’ long and produce a perfect tenon to exact dimensions in under 20 seconds. The same machine will deliver oak rails 2-3” thick by 12” wide and four feet long to the bench top with or without tenons. The Roubo bench itself is a fine looking bench, the question is, do lightweight benches offer the same advantages and the fact is, for the main part, I think that they do. To describe hard maple as tough and resilient would be a true statement, but again, the reality is I would defy anybody to say that pine and spruce are any the less resilient for the task they perform and the tasks we perform on them than hardwoods. It does seem that we live in an age where we keep coming out with sledge-hammer mass and weight to crack the proverbial nut when smart work beats hard work any way you slice it. I think that it is true to say that some engineers complicate what is really quite simple because they like a particular concept. This presents woodworkers like me with something of a battle because the complexities surrounding certain aspects if woodworking are often based on the views of engineers and not woodworkers. This was and still is my battle with the #4 Stanley smoothing plane versus the heavyweight planes now being produced on the three different continents. At first I was very impressed with the Clifton bench planes. They seemed really fine and indeed they really are finely made planes. After a while of using them though I realized that they took a much greater amount of energy to use them and that because of their weight they were less versatile than the Stanley or Record counterparts. Ultimately I concluded that the Stanley deserved recognition as the best plane ever made because of its wonderful nimbleness no matter the opposition. I gave fair play to the heavyweights from all three continents in that I tried them all and worked with them for extended periods and concluded them to be lacking. I felt that it was time to extol the real values of owning a good old Stanley #4 bench plane. The same is true of very heavy benches made from hardwoods. Those that want a heavy bench can buy or make one without criticism from me. They will be nice benches I am sure. The problem lies more in the fact that they are beyond many new woodworkers to build straight off when they indeed need a bench to get started. The bench they can readily make with so little experience should be the one they stay put with because it has real value to them. I like that.

To conclude

I find quick release vises with a sash or bar clamp for dogging beats any and all stock holding devices I have seen develop through the years. They are fast, expansive and hold stock solidly with single-handed movement. I like aprons to my benches and I have seen many people alter the Roubo bench to incorporate aprons and quick release vises to their benches, which is how benches evolve and, for the main part, improve. Some people like authenticity and some like functionality, a rare hybrid. The well in a bench is really a no brainer for me. The tools are safe and out of the way for the main part. Wells work well!

Comments ()