Robert Sorby chisels compete with the best

Sorby chisels cover the spectrum

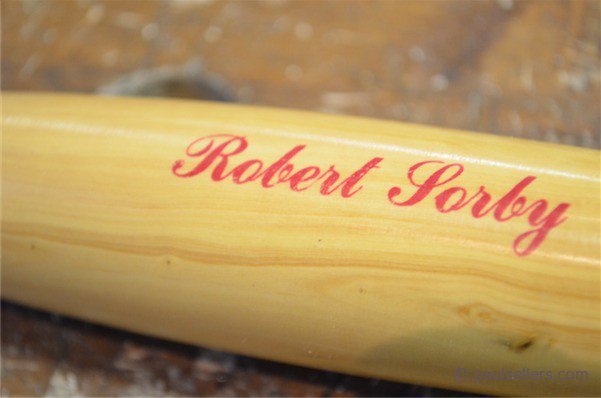

I think many people feel the same way I do and that is that plastic handled chisels work well and will equal the performance of some of the most expensive chisels produced. I try to present tools of value that are suited to task first, affordable and comfortable to use. We have covered some of the less expensive chisels recently and so I wanted to tell you about some of the best chisels on the market that are still affordable, well made and of perfect conformation. These Robert Sorby chisels are, well, lovely. And, of course, you cannot dismiss the aesthetic appeal wood has in the hand. Boxwood handles far exceed all other handles for several reasons not the least of which id the incredible strength boxwood has and it's resistance to splitting and end-grain collapse.

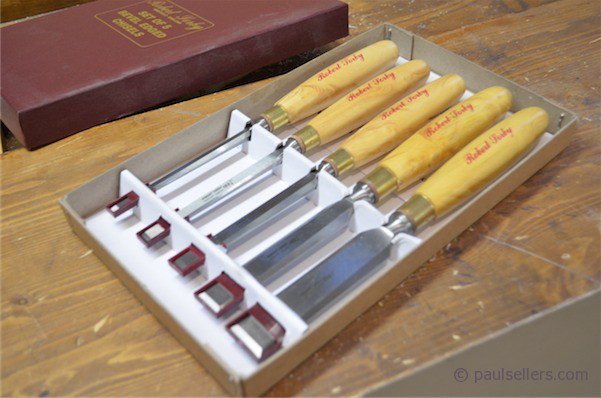

The three sets I ordered are two sets of boxwood handled chisels and a set of plastic handled chisels made from a plastic known as C.A.B (Cellulose Acetate Butyrate), a virtually indestructible material producing the ultimate unbreakable handle.

I have expresses pretty strong views on some tools and especially the heavyweight planes that dog us and have unfortunately displaced truly wonderful planes that stood the test of time for over a century. My perspective is unlikely to change on this issue and those who have tried to change my perspective inevitably found the benefits of a #4 Stanley or Record had many more advantages to enhance their woodworking with. When I run heavyweights alongside my plane-Jane #4 Stanley, the comparison is the equivalent of racing a working plough horse against an Arabian stallion or an English Thoroughbred breed. Heavy and sluggish, the too-heavy draft horse is strong and powerful for lulling, lugging and ploughing but far too overweight for the task of running, jumping, dressage and high demand sports such as polo where agility, speed and spirit give perfected versatility. Some of our modern chisels fall into this category and have become sluggish, imbalanced and dead ugly.

I ordered three sets of Robert Sorby chisels because I have used some of their classic London pattern chisels for about two decades now. First off is that the chisels present well in a quality cardboard box on arrival. This then places a real sense of value in the product and that alone speaks of how the Sorby name for quality continues today. Having been familiar with the high quality of Sorby’s full range of woodworking chisels, and I’ve also used their turning tools for almost three decades, I had high expectations for what I hoped would be a continued production of heirloom-quality tools. I have wanted a domestic chisel I could recommend for some years and decided to visit the UK to see if Sorby was in fact still equal to my expectations in producing the quality they were known for back in the 80’s and 90’s. I was not disappointed. Unlike many UK manufacturers importing from Asia yet increasing their prices but buying cheap so that their bottom-line profits are uppermost, Sorby still make their chisels here in the UK. Had the standards declined? Not at all. The chisels arrived and matched what they were 20 years ago.

Fairly standard to any chisel is that they are ground to 25-degrees. I really don’t want a chisel to arrive polished and sharp. It’s of little real value or purpose. With an hour or so they need sharpening anyway.

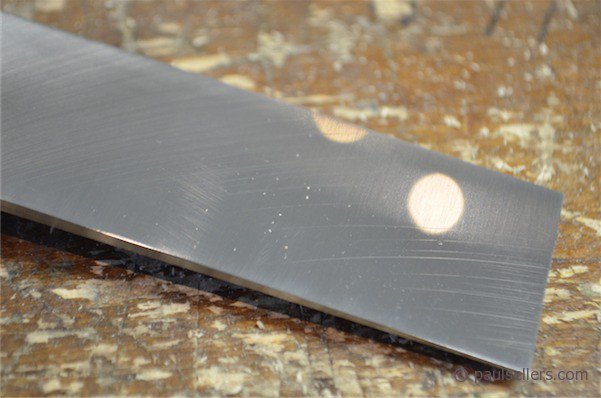

Sorby chisels are individually tested for hardness before they leave the factory so expect the small dimple from their test in the flat face of the chisels. Their hardness standard is complying to BS 1943, which sets the required standard for hardness, bend tolerances and flatness. The chisels are plenty hard enough yet still tough enough for a durable and long-lasting working edge. I want a chisel that flexes slightly yet doesn’t break. The bevel quickly transformed from the standard flat bevel to an ideal convex bevel and soon I had the polish I needed for a pristine paring capability.

In my class today we examined the chisels and sharpened them up. They were resistant enough on the EZE Lap diamond plates and flat enough to be lapped dead flat in a minute on the granite slab. You can see the grey dot from the diamond tester about 3/4" from the cutting edge and also the abraded surface that must be further refined to get the optimum cutting edge that parallels the bevel in quality.

The first set of chisels felt perfectly balanced and I liked the larger boxwood handles captured in the traditional brass ferrule and the integrated leather shock absorbing washer.

These chisels are indeed heirloom quality and anyone could work them further to personalize them as many people like to do.

Comments ()