Buying Good Tools Cheap - The Router Plane

Routers online

Routers for most people conjure up a range of different images ranging from face shields and dust extractors to dust masks ear plugs hearing protection and other head gear resembling and American football team player or a SWAT team member. Of course for 99.9% of machinist woodworkers this is essential equipment. That equates to most woodworkers and as we know, they are not so much working wood but working machines.

From my culture these images are not so much a part of my psyche. I wish that were so for more people too.Mention router and I automatically think of a Stanley #71 or Record #071. This plane type has been very much a part of my working tool arsenal for decades, and, although I like these makers quite well, Veritas routers are indeed the best modern-day maker of router planes.

The main difference between the two planes is the nickel plating of the Stanley and the painted casting of the Record in the Record blue colour. Both seem to last about the same with regards to rust prevention and if they are used well, which all of mine are, they don't rust that much at all.

Both of these models were made in England as can be seen.

My totally favourite router plane is one once made by Edward Preston. I love the long rectangular base and would that the Veritas, Stanley and Record router planes had the same sized and shaped base. Actually, I bought two router planes this past week; one was indeed a Preston and the other a Tyzack. These don’t come up too often on eBay, but my recent find left me buying the very rare Tyzak for £19 and the Preston for a buy-it-now of £55. The two planes, though made by different makers, are almost exact mirrors of one another in shape and size and most likely came from the same casting foundry one way or the other. This often happened in Sheffield in times past. Both routers are excellent. Unfortunately it’s unlikely you will find one again. I see one every few months but this is on a diminishing level. The attention to detail is what drew me to these planes, so let’s take a closer look.

Why this router is so good?

The main aspect I like about both the Tyzack and the Preston router is the larger platen that distributes over a wider surface area of the wood being worked. I also like the openness in the frame casting which allows for full vision of the wood I am working. The extra length gives me the ability to work tenon cheeks more accurately and with the extra leverage this sometimes needs, I find it takes less effort.

I also like low profile knobs on routers, a criticism I have of all other routers. The lower the profile the nearer the centre of thrust approximates the centre of the cutting edge and the less over-leverage I get that can cause the router to trip as most of them do from time to time. I also like the minute detail in the knob parts being brass and with the undulated rim that gives dead-on alignment and sure fixing.

#71 and #071 models

The collars and mechanisms of both Tyzack and Preston are the same as the Record and Stanley as you can see here and top two pictures.

Both Stanley and Record produced the #71 models with only slight variations on the the theme. Traditionally, Record added the '0' prefix to their numbering system on planes following the Stanley styling. These tools have proven steadfast and substantive for a century and more and aside from the cutters getting too short to sharpen after decades of use, these tools last, work and work well.

They come up often enough on eBay and generally have all of the original cutters in unused condition. These past weeks I bought about ten of them to see how much on average they would sell for. My average price was £25. I think that that’s excellent value for money so wait a week or two until the bidding drops to normal again and buy yourself a bargain as they occur. No one should be without one of these tools.

Old woman’s tooth

These planes work fine too. I used one that I made for years and then left it in storage and haven’t gone back as yet. I did a blog post here on a poor man’s router also, made from an Allen key. With the Old Woman’s tooth, also call a Hag’s tooth, we used to use the wooden plough plane irons for the cutting iron. I think that the metal planes work more accurately for my work and of course the reason is that they give me the infinite adjustment I want for micro adjusting depths of housings and so on that I get with the threaded depth adjustment mechanism. Take this away and both wood and metal routers work with equal ability and of course wood on wood always feels best. To cater to this, most all metal planes have screw holes for attaching wooden soles. Wooden soles soften the contact between the tool and the wood and are less likely to damage the work. This is especially important on fine work such as veneered surfaces and inlay or marquetry work.

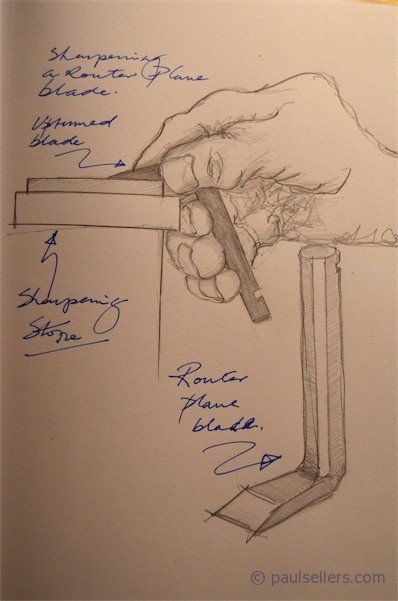

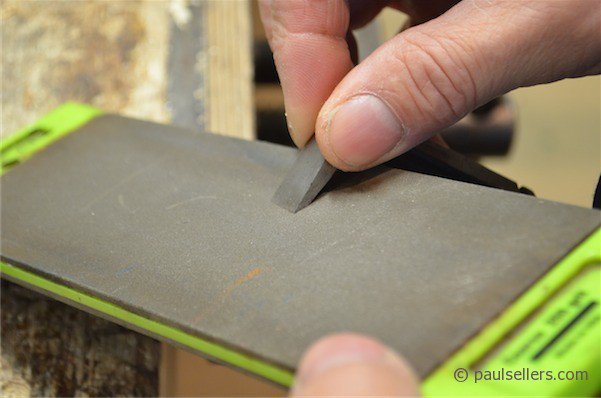

Sharpening router cutters with fixed, single-piece cutting irons

These cutters don’t generally need the same level of sharpness say the smoothing plane iron generally demands, but they sharpen easily on diamond plates and I keep a two-sided EZE lap for this purpose. I rest one corner against the vise and the other end in my belly. I then adjust myself to grip the cutter upside down and rub the cutter back and forth until I have a good angle on the bevel. Once that’s done, I turn the cutter correct way up and hone the underside of the shoe-shaped cutting iron. I start on 250-grit, go to 600 and finish off at 1200. That’s enough for a router plane.

Comments ()