Making a saw file handle in two minutes

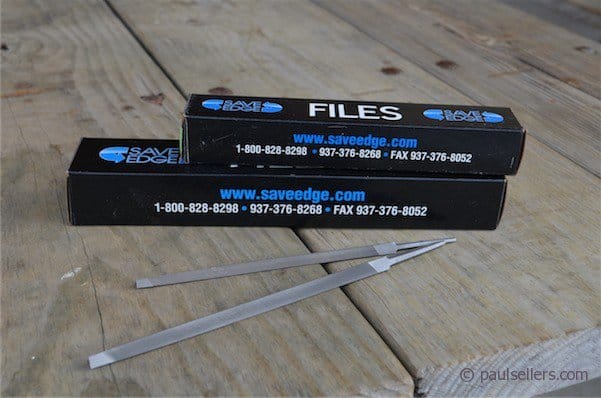

OK, you are buying files in Europe and they are for the main part all double ended so you get two files for the price and material content of one. Most people use only about four inches of a saw file because that's all the length required to get the cutting edge they need for each tooth. US saw files on the other hand, are mostly tanged and with that slender pointed end you should never try filing without a handle. Very dangerous: tang point punctures and worse still slides into vein in wrist. Very painful.

Tanged file handles are inexpensive but when you can;t find one or someone is using yours you may need to make a quick one. Here's what I do, all too often.

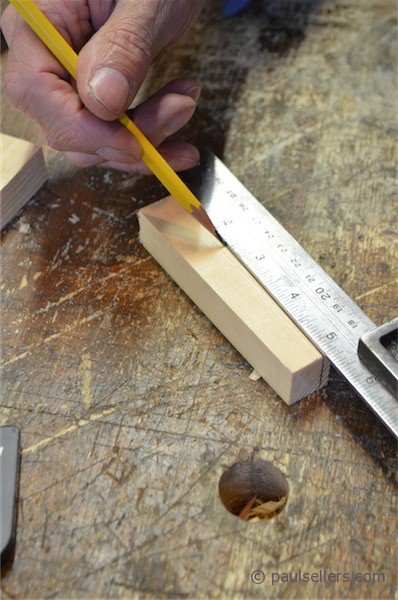

Split any piece of wood and pine will work fine. 3/4" x 3/4" x 4 1/2" long.

Mark a tapered guide line from 3/4" to 5/8" onto the blank as shown.

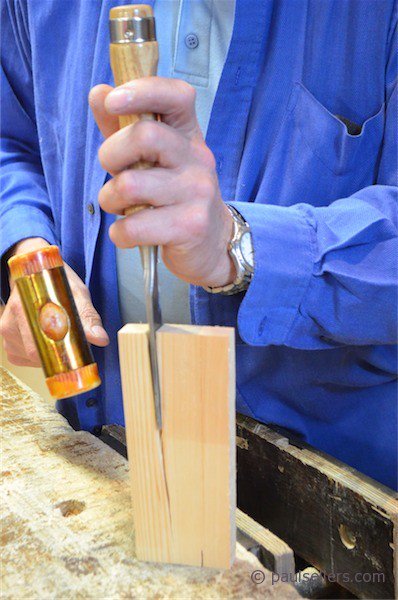

Use a 1" chisel to taper two faces down to 5/8".

Use a finger guide to run lines along both edges of all four corners.

Chisel a chamfer on the corners.

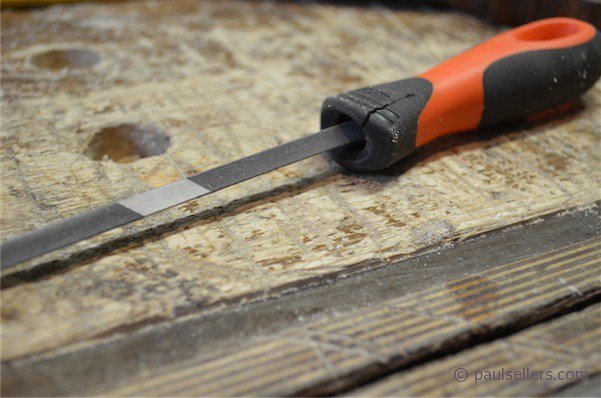

Use a file or sandpaper or a chisel to remove the end corners for neatness and comfort.

Do both ends.

I used a square awl to crest a hole for the tang. You could also use a drill/driver or do as I did and put the built into the vise and turn the handle into the drill bit to the depth needed to receive almost but not quite the full length of the tang. I stopped half an inch from the file proper. Jobs done.Filing begins.

h

Here's how it looks when done.

Sent from my iPad

Comments ()