Health where we work

The machine shop

The workshops in New York were purpose built in two halves. Something I have always aimed for in my own life since the mid 1980’s. There is nothing unhealthy in a hand-tool-only workshop, but as soon as you introduce power equipment, hand held or stationary, that all changes. A lot of woodworkers insist that using extraction resolves the issue but by that I sometimes think that they mean a clean shop with no sawdust and planer shaving lying around in piles on the floor. This to them means health and safety is complied with, but in reality, whether they are in a bag or on the floor in piles is not really an H&S issue. Of course there are no health and safety regulations in place for home or private individual workshop shop use. Regulations generally cover commercial shops with employees and multiple user facilities. Even there, most shops do not comply with every machine. In home or domestic workshops we owe it to ourselves and those around us to be health and safety conscious. Dust remains in the atmosphere for hours after the extractor is switched off. The first thing we do when we switch off the machine is remove our dust masks yet the most harmful dust of all is the fine dust in the atmosphere that escaped the extraction units. What better way than to walk out of that environment and into a dust free hand tool shop. Dust is a killer. We develop allergies to wood types. No wood dust is safe dust; especially in your lungs, throat and nasal passages.

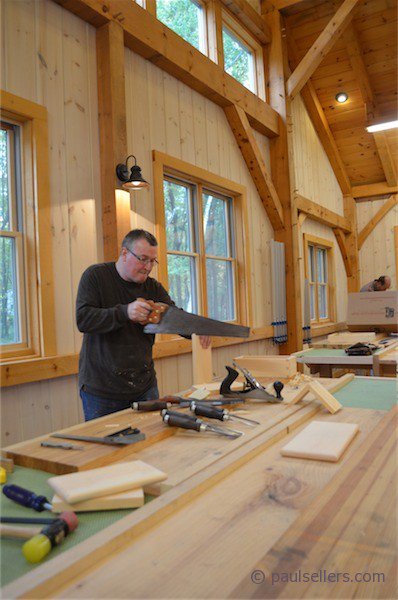

Of course I have the ideal situation. A large and lofty machine workshop adjacent to a vaulted timberframed structure with lots of windows for natural light and absolutely no dust. We never use any type of power sanding in here so accumulated dust really doesn’t exist. With regular cleanup on an-end-of-day basis and a good deep clean once a month the shop stays healthy. That’s the same for the machine shop. Each user cleans up after use or at the end of the day which ever comes first. The shop stays orderly and clean. Each machine is hooked up to an extraction unit too.

If you don't have the ideal separation of the two areas, I suggest that you have a milling day or period where you calculate all of the dimensioning needs and then mill until done. Open the doors of the shop as much as possible and let the breeze blow through for an hour while you take a break and have a cup of tea. Returning to the shop you will be in a dust free work area and safety.

In the UK we have two separate shops but this time they are a mile apart. The Castle has only one bandsaw, which we use perhaps once or twice a week on average. All other machines are in a dedicated workshop beyond the castle. Some might say not too convenient, but with good planning and forethought it works just fine. Remember we get good crossgrain cuts with handsaws that equal the chop saw and we don’t rely on machines for any of our joinery ever.

You see, that’s the power of hand tool woodworking. It works!

Comments ()