Buying good tools cheap - Introducing the hand saws

I am going to risk it

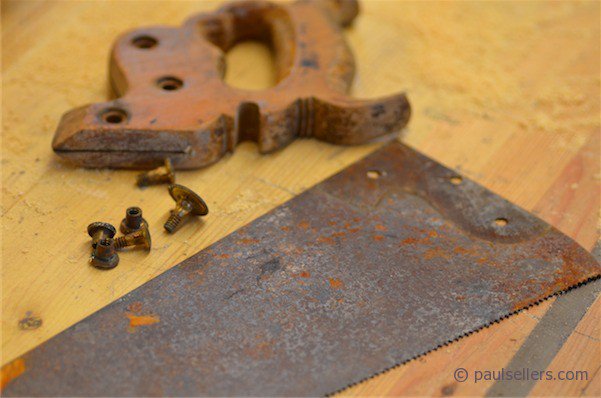

I own a belt sander 4” wide. It’s made by Trend and it’s a piece of poor workmanship but the price was right because I could see how to improve it for what I wanted it for and this is where I take the risk. It’s really the risk of criticism. One is that people think I never use power equipment but I know more about power equipment than I do hand tools. I grew up with both from the start. The second risk is the criticism I will get when I tell you what I use it for the most. I restore rusted saw plates, many of them, before I begin reshaping teeth and sharpening and setting them. The plates are often badly encrusted with grunge, oil and rust. Some are too bad for hand work with sandpaper and yet underneath there is fine tool steel in the plate. By removing the handle I can use the wide belt sander to remove first the grunge and get down to steel and then the surface of the whole steel plate on both sides. As plates on the better saws are taper ground, using the belt sander enables me to ensure that the saw is indeed taper ground and if not I use the belt sander to effectively create a taper grind to the plate. I can even remove surface pitting caused by rust if a so desire, but the main thrust is to get the saw plate into a position for full restoration. I use a 120-grit belt for the first serious pass and then follow up with a 220 belt. The plate feels like silk and glides through the wood like a hot knife through butter.

Safety

Your safety is always your issue as well as but more than mine. If you don’t feel something is safe, don’t do it no matter what I or anyone else tells you. A couple of things you should be aware of. One, make sure that the plate is securely clamped to the bench top. The friction from the abrasive belt can grab the saw and send it flying like a frisbee. Secondly. remove the nylon woven dust bag. If sparks enter the bag they can combust sawdust and also melt the bag. When completed, check the belt sander to make certain there are no sparks seated in previously accumulated sawdust that might cause combustion. I have never had an incident using a belt sander for this purpose and the plates do look like new when done thoroughly. Take care that the belt sander doesn’t dig in as this is hard remove and unsightly. Start the machine off the saw and lower in a backward movement and then work in long forward stokes moving backwards and forwards in long strokes with even pressure.

Most of the saws I work can be surfaced with only hand rubbing using wet and dry. Use this belt sander method only if hand sanding won’t get you where you want to be and the saw is going to make a good one. I use older worn belts and I have some lovely saws using this method. It’s obviously not worth buying a belt sander for one saw. This is for those who have one or plan on doing many saws.

Handsaws are remarkably inexpensive on ebay in the UK and even in the USA they are not too pricey. I have used some very poor saws made by modern makers you might expect more from so buy with caution. A good Henry Disston or Spear and Jackson can still go for $30 in the USA and £15 in the UK. No money at all for a lifetime tool.

Tom and I were talking today about throwaway saws not being taper ground or skew backed. He wondered why that was so. Well, the fact is these saws are engineered and they are engineered not so much for all round cutting of wood but for a different woodworking culture. Most carpenters no longer work wood as such but so called engineered material. Rarely will a carpenter ripcut a 2x4 along its length but they will crosscut from time to time in an awkward space that disallows a skilsaw. When I say that they are not really designed for cutting wood I meant that they are designed for what carpenters work most, which is of course plywood (50% crossgrain), particle boards, OSB and MDF, none of which have any single grain direction if they have grain at all. So these disposable saws are fit for purpose in that they need hard-point teeth to cope with the hard resins and fillers used in the manufacture of sheet goods and also surface covered boards such as plastic laminate and melamine. For woodworkers using only real wood for most of their work, these saws are at best only 50% efficient 50% of the time. We need something more versatile and direct and that’s why we often need dedicated saws for rip and crosscut work.

Comments ()