Questions answered on flattening chisels

Miles has asked me what to use to flatten a belly on the large flat face of a chisel because he can't seem to get one corner of an older Marples' chisel. This should take no more than 3-4 minutes as Marples are not particularly hard chisels and this then becomes their main advantage in that they are readily sharpenable. He also tells me he is thinking about what abrasive he should use and asks what I use.

Answer:

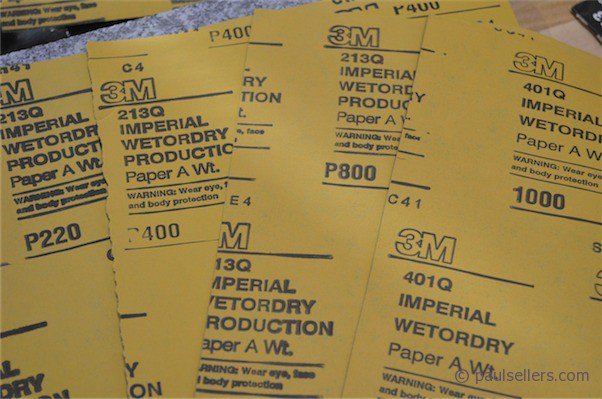

A couple of things come to mind from my experience. I generally use plain ol' wet-n-dry and start with anything between 180-240 grit.

I use a light (I mean light) misting of spray adhesive on the reverse side of the abrasive paper to prevent slippage but also to prevent the paper from rucking up in front of the tool edge, which is the most common cause of roundover on the flat face at the leading edge.

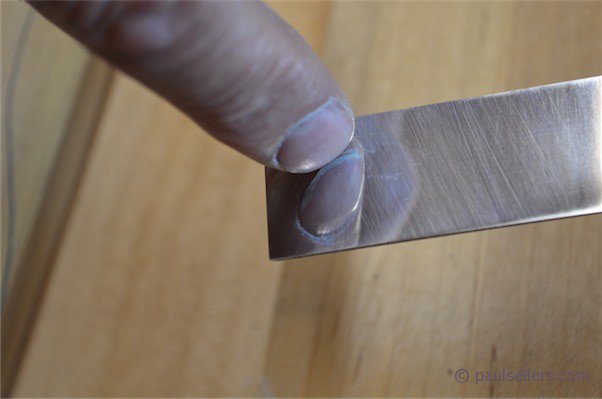

A squirt bottle with water keeps the surface from clogging. An important point here, and this can well be your problem too, is that, when you push the chisel on the forward stroke, there will be a tendency to hold the chisel with the dominant hand, pushing the chisel on the surface at an angle so that one corner or the other enters the abrasive before the remaining long part of the edge. Thus you can cause a build up of abrasive on the fore corner of the chisel with each successive forward push. This then also tends to be the more aggressive and productive stroke. Because this is the leading edge it becomes more like a bulldozer causing a buildup at that corner point. Any stroke, and there will likely be many, that goes over this rise of particulate on the surface will receive a mega dose of particulate at that corner and in a matter of seconds you have created your own problem of rounding the corner and even the full leading edge of the flat face of the chisel. Try trailing the cutting edge more or presenting the chisel square to the paper as shown, so rather than pushing the important cutting edge into the particulate you are pulling it. Also, don't just wet the wet-n-dry, flush it with water so that abrasive and steel particles are flushed more evenly over the surface or even off the surface for that matter and not allowed to build up where the push strokes stop. Remember that the abrasive is very hard and aggressive and doesn't stop cutting when it surface fractures from the substrate of particulate below.

Don't skimp on a granite block.

Not all blocks are truly flat as I discovered when I tested one we used at the school.

Here in the UK I purchased a certified block from Tilgear that proved dead flat:

Here is the link to their website too. They have good pricing and fast delivery: http://www.tilgear.info

DIA0912GP - Diatec granite surface plate, dimensions 9in x 12in x 2in

Another concern to seriously consider is that the sub plate support you sharpen on is truly guaranteed dead flat and not even slightly undulating and that it's also thick enough or supported enough not to be flexing with the pressure of the stroke. For instance, unless float glass is fully supported, it will flex. Even double sided tape allows a measure of flex in glass. Any of this will cause rounding on the fore corner of the cutting edge. Of course the worst scenario will be if the platen, slab, tile, glass, granite or whatever you use is itself indeed hollow.

All of the above has not so much to do with the size of the abrasive particulate although large grit particulate will round more. You must take care throughout each level.

You will be amazed at the significance of using a dead flat chisel in your work at the bench. Machine-only woodworkers never enter these realms of working wood. It should take no more than five minutes to flatten a 1" wide chisel to a polished face as shown. remember also, if a chisel is dished as distinct from hollow, you do not have flatten it. As long as there is about 1/2' of flatness directly behind the actual edge, all the way up to the edge, and the sides of the chisel have some flatness continuing from the edge, it will operate exactly the same as a dead flat face. It's only convex surfaces that need flattening.

Sorry this was so long.

Comments ()