Workbenches—going to the dogs?

NOTE:Just so you know, this is an older workbench series. Paul has a newer Workbench series. If you are interested in the updated version of Paul’s workbench please click the button down below. This page links to a cutting list, tools list, FAQS and much more.

Click here to go to the workbench page

When I was a boy apprentice, the benches I worked on were two-man benches. At 15 years old I was considered an adult and worked as a man even though the older men called me “boy” or referred to me amongst themselves as “the boy.” I didn’t mind being “the boy” at all. Moving up the hierarchy of apprentices, it wasn’t too long before I moved from the lowest dog position to 2nd, 3rd, 4th and 5th year and a fully-grown craftsman.

All of the benches there looked the same. They were beaten and bruised, sawn into, chiseled into and sometimes planed into. They were screwed into, nailed into, clamped and cramped on to and the overall appearance was a scarred workbench. Because of this, I care little for polished benches that don't invite work and even though I take great care not to axe into or chisel the surfaces, I find slick, highly finished bench worktops less than, well, working examples to be emulated. Now that does not mean that they are no good, or that someone is a lesser woodworker if their benchtops are not severely marred. Simply that I don’t want to feel I need to spend more time taking care of my benchtop rather than working wood. Anyway, this is how I feel and not for everyone. All of this is to get to my point, which is that every workbench I ever saw looked like the ones described and that is generally how my benches look in the everyday of life. Furthermore, men I worked with felt nothing about nailing a bench stop of 1x2 across the end of the bench and planing a stile of a door or a window frame. The stop might stay there for two weeks and then removed. The same stop was kept for future work and that was that.

There are many questions people have surrounding benchdogs and dogging systems and I indeed included a setup in my recently completed workbenbench to address the issue. What I have worked out is that most of use the bench top for stuff that will not fit into the vise. My Woden vise will take 14”. Quite large and very solid.

A highly effective method

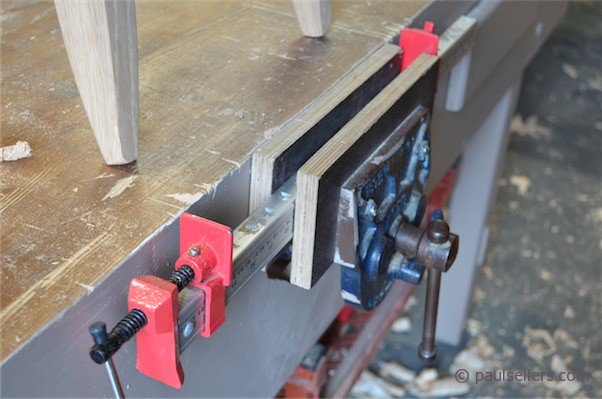

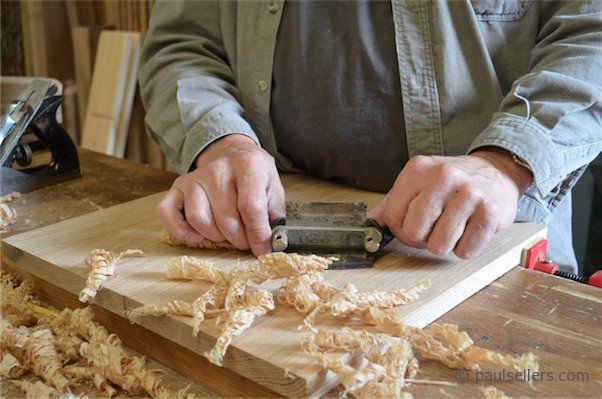

One method of work holding I have used for a few years is the sash clamp held in the vise. You must however infill the aluminum clamps I use with wood beforehand. I do this as a matter of course on these clamps because it so improves the quality, feel and torque resistance on (see earlier post on retrofitting clamps) alluminium clamps.

A four-foot clamp will arrest a full table top on the bench and will also hold something 2” square or less. I place the work in progress on the benchtop and then secure the edge overhanging the bench edge and vise in the clamp. A 2’ x 3’ coffee table top can be readily scraped and planed and sounded without movement or vibration. Notice that I can change direction to plane away from me across the bench or along the bench. Long tabletops can span the benchtop and be worked from either end or turned around for comfort as needed.

As you can see, long legs and such fit readily into this system. Round or square, long or short pieces and even many awkward shapes can be safely and securely held using this system and many other such adaptations too many for this blog are possible.

This system is especially good for children who may not have the strength to use a bench hook, which is actually more upper body weight transfer to the arms rather than actual strength.

For the legs, I usually anchor the leg in the clamp clear of the ends so that my plane or spokeshave clears the clamps heads and then lower it into the vise so that the leg is then also supported by the vise jaws.

Look above also at the tabletop. I do the same here; I clamp the workpiece free and clear and lower it into the vise until the tabletop is fully supported and tighten the vise onto the clamp bar. This system also works well with pipe clamps (USA) and sash clamps too. It's wonderful for scraping too.

Comments ()