One more mortise

There is a thing about mortise cutting and chisel edges that matters. Robert Sorby mortise chisels (and most others) arrive with a micro-bevel on the cutting edge. In the pre 80s no chisel arrived with anything more than a ground edge. I think it's a silly thing to send chisels out with honed edges, but that's just me. It's no big deal and it helps people get going straight away. But I do think it's a silly thing to send out a mortise chisel with so small a cutting edge as that.

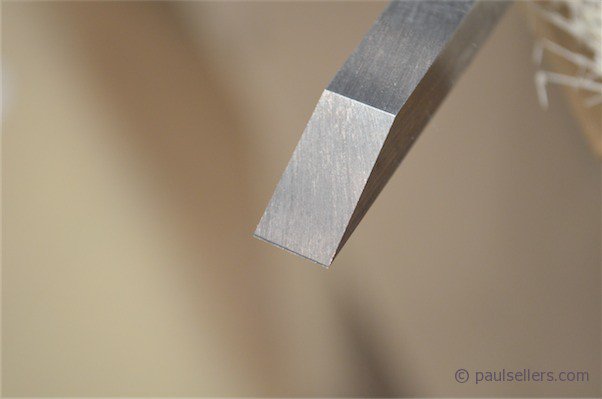

This would be a better size really. Good, strong and it takes less than 5 seconds to do.

I use a macro camber and so I changed the manufactured edge to suit me. It takes two minutes to create and it will now be maintained for the life of the chisel.

Oh, and I also make sure the back is flat and polished straight off the bat, or slightly hollow if it comes hollow a little bit. 2,000 grit is plenty. No need for more for mortising. Even 2,000 is an overkill.

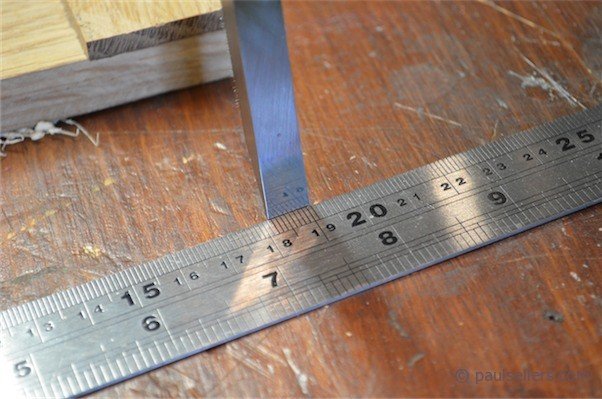

This chisel is really a fine chisel and has a 3-degree slope to each side of the chisel so it doesn't bind in the mortise as you deepen. One thing. UK manifacturers compromise accurate measurements on the widths of chisels and describe chisels as being 13mm or 3/8" but these two measurements are incompatible. using imperial measurements with metric is never accurate so one or the other or both will be compromised because the cater to two different continents with two different national standards. Britain abandoned imperial back in the late 60's, but retained its US market to supple imperial measurements on tools.

I still haven't found a better chisel than a bevel-edged for motoring into the mortise though. Have fun!

Comments ()