Chopping mortises - bevel-edged or mortise chisels (video)

Chopping the mortise--Bevel edged or traditional mortise chisel

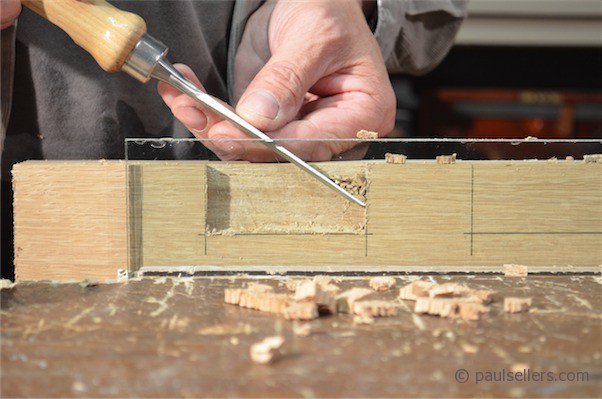

I recently saw a Youtube video put together by Lie Nielsen where it shows a mortise being cut behind glass; the idea was to show the progression of the traditional method using a traditional 'pig-sticker' mortise chisel and I understand it was Roy Underhill who came up with the idea, which was wonderful.

As a boy in school I was shown this method and indeed we were trained that way, but once I left school and started to chop mortises in the everyday of life I found that lightweight chisels chopped more effectively, especially on the lighter work of furniture making and joinery rather than the heavy bank doors once common that had 3/4" wide 5" x 5" deep twin and double mortises in mahogany and oak (that's two or four mortises per corner sometimes on the bottom and middle rails). In my apprenticeship, most of the men chopped mortises with a Marples bevel-edged chisel. They used the ones shortened by wear, admittedly, but I used my then brand new Marples bluechips and have done so now for almost five decades. In all of those years using these and other makers, I have never bent a chisel once. Furthermore, I have trained 3,500 woodworkers, many raw beginners to the bench, and I have never found one chisel bent either.

https://www.youtube.com/watch?v=q_NXq7_TILA

Growing in my craft, I found myself changing the pattern and developed the one I teach and advocate today. No matter the chisel, this method is fast and highly efficient and so effective I find myself able to consistently chop a 4" long mortise 1 1/2" deep and 3/8 wide in around 4 minutes. I own a mortise machine, but seldom use it because of this. Anything and everything you have seen me work on in the past three years has been cut by hand methods.

My reason for staying with the bevel-edged chisels is indeed as much the size of the bevel cutting edge itself as the thinness of the steel chisel used. Obviously, because it's so small (narrow), the steel penetrates very effectively in any wood. The lighter weight of the chisel means I can easily drive it with minimum counter-opposition from the weight I inevitably get with the heavy framing chisels.

Sparked by the idea of the Youtube video, we decided to show the method I used and at the same time try to show the contrast between the traditional mortise chisel and the bevel-edged chisel. The reason being that traditional mortise chisels are not so readily available and accessible to everyday woodworkers and to show how effectively this method works with either chisel.

Working on massive doors in the pre-machine age and making such projects day in day out I would indeed use a heavy weight traditional mortise chisel. I worked on two large doors for the National Trust's Penrhyn Castle two years ago and so I do not challenge the ancient craftsmen who used and developed them for such work. Neither do I challenge them for fine work either. An English five-bar field gate had ten mortises 3/4" by 4-5" through stile 4-6" wide and a man made one in a ten-hour day complete with bracing in solid oak. That man used the kind of mortise chisel I am talking about. These chisels were wonderfully made to last the lifetimes of two craftsmen. At the everyday bench for we woodworkers, we use good chisels carefully and work with what we have at hand.

Comments ()