Another poor man's router

Poor man’s router

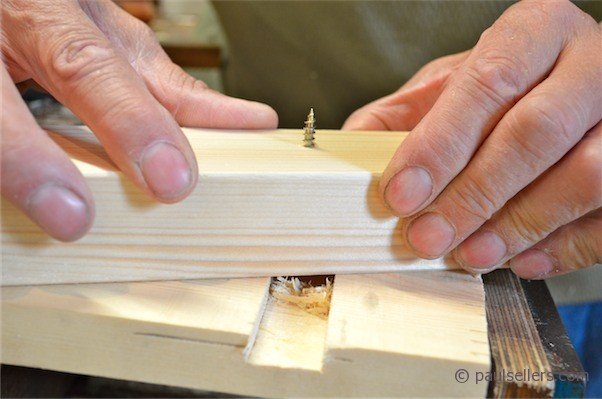

Someone recently shared with me a jobsite poor man’s router he uses regularly and I tried it out in an inspired moment recently. It’s made from a #14 (about 44mm shank it looks like) screw and block like the poor man’s beading-cum-marking gauge I have posted on in the recent and distant past. This is infinitely adjustable with screwdriver or screw bit in a drill-driver. Probably everyone knows about this except me, but there will likely be some of you that don’t. Here are my findings and resolutions.

I found that the screw alone didn’t work at all. No surprises there, rounded edges machined in every modern screw, but even when filed the flat head face of the screw with a file and thereby sharpened the rounded edges, I found that it clumsily stumbled in the recess. Analyzing the whole, I concluded a couple of issues. One, my expectation of a push-me-pull-you wasn’t realistic. The accuracy levels of hand filing the rim of a screw to lie perfectly level and parallel all around to a recessed surface wasn’t going to happen and if it didn’t the tool would be absolutely intolerant of any and all ineptitude on my part. Two, just as with a regular hand router cutting iron, the cutting edge could only cut effectively if the heel was higher than the cutting edge. Once this was resolved, the router became a highly effective cutting tool that readily developed a pristine cut resulting and a perfectly surfaced recess as good if not better than any developed specialist router plane.

Because the angled head is angled, and the cutting edge is only one half of the screw head, that meant that turning the screw for infinite adjustment would be compromised, but by slewing the stock of the 'plane I found I could easily continue with my work even though I forfeited any alignment of my stock perpendicular to the length of my wood.

Oh, safety issues are your responsibility every time, so remove the excess screw point before use and don't risk the palms of your hands.

Comments ()