Recutting a 7 tpi Disston to a 14tpi

I bought an eBay Disston last week, amongst some others I had bought. It looked a little rugged with larger teeth than seemed natural for so fine a saw, but £10.50 didn’t seem too much for an original 10” Disston #5 brass-backed saw. I own one of these already and have had it for 20 years and I must say that it’s still my favourite saw of all. It’s also the best saw I own and so buying this seemed a good idea.

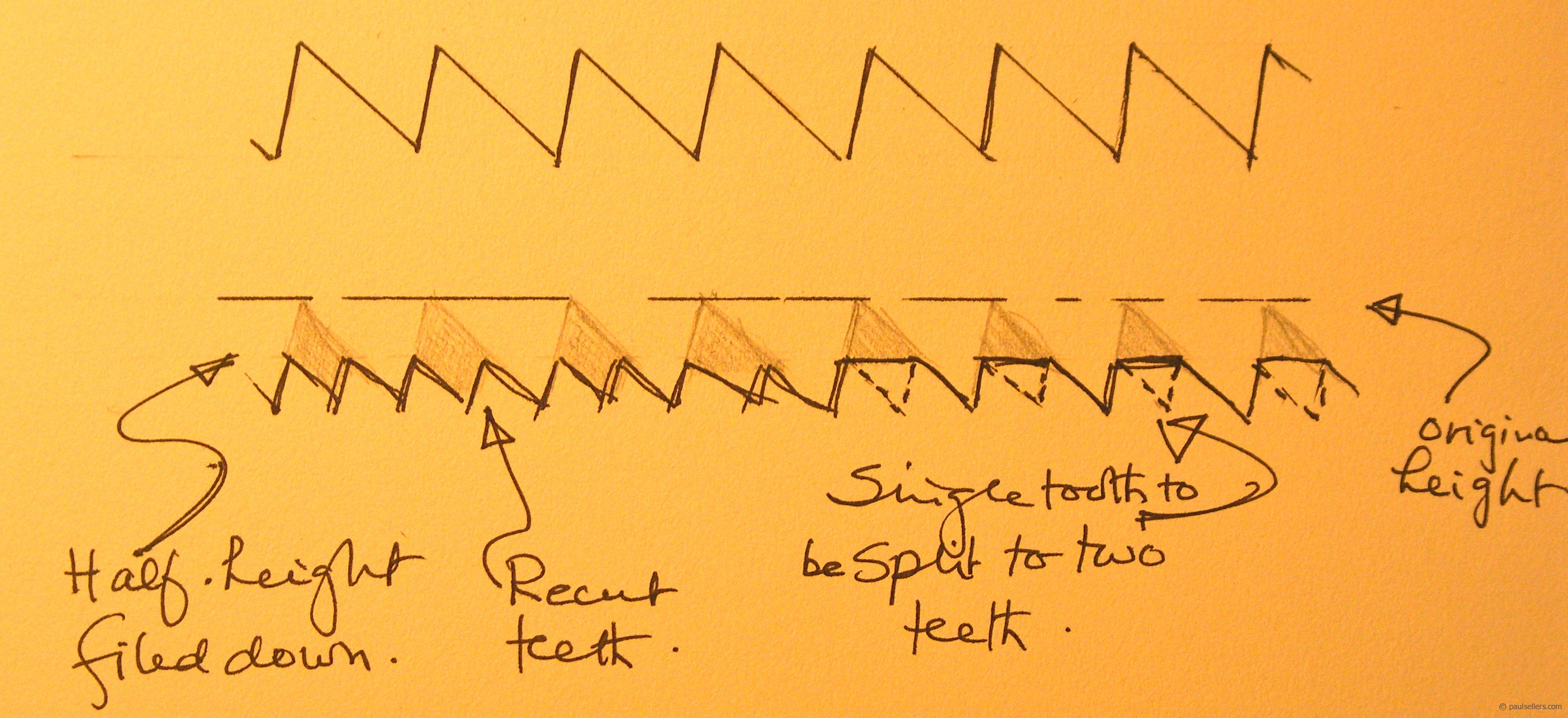

This saw proved to be a good rip saw but teeth at 7 tpi can be a bit big on so small a saw. It ripped OK but precision wasn’t in it. Too much set by far. First I removed 90% of the set and it cut much more efficiently and kept good course with a thinner kerf. I needed to recut the teeth to a smaller size and as 14 tpi is ideal for this length I decided to double the amount of teeth. Sometimes I recut the teeth on saws because teeth are too wildly shaped or have too many or too few teeth. Often in such cases it’s simply easier to file off all of the teeth. In this case it’s easier to halve the size of the teeth and thereby double the quantity.

Shaping teeth

A prerequisite to creating a saw is to shape the teeth. Regardless of the tooth type; fleam cross cut, passive or aggressive rip cut or whatever, the shape is critical to subsequent setting and sharpening. All dovetail saws are sharpened to a ripcut pattern.

Topping teeth

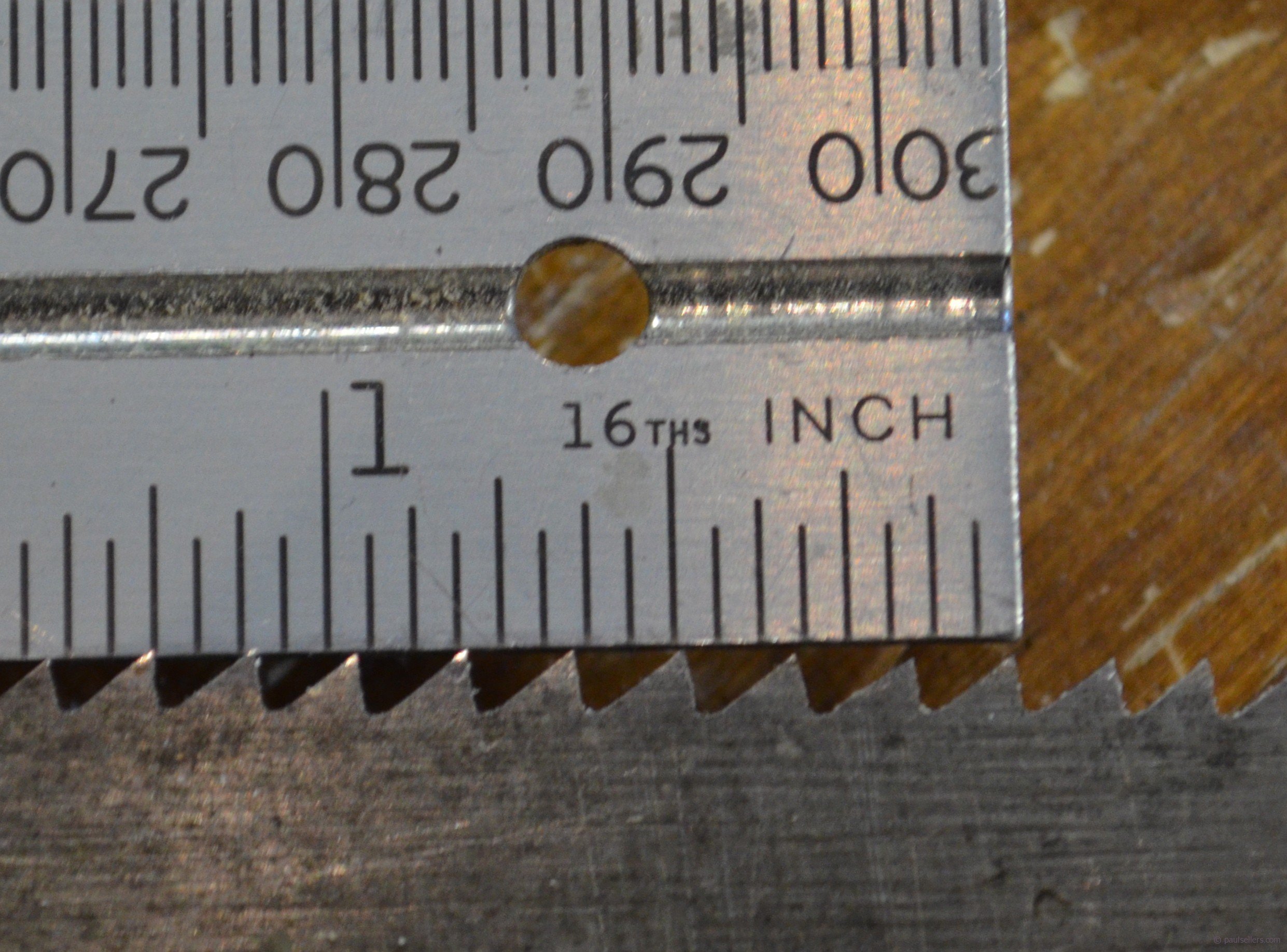

To convert two teeth to one is one of the simplest of conversion sizes and the simplest to cut. I begin by first topping (jointing USA) the saw and halving the height of the teeth. Any single-cut, flat file 8-10" long will quickly cut the teeth down to half height with about ten strokes depending on the thickness of the saw plate and the evenness of the teeth etc.

The teeth will look like this.

Now it’s simply a case of cutting the new teeth by filing with a 6" extra slim tapered saw file. Nicholson files work well for this but are not too readily available in the UK. Draper saw files work fine and I have used them here in the UK.

Comments ()