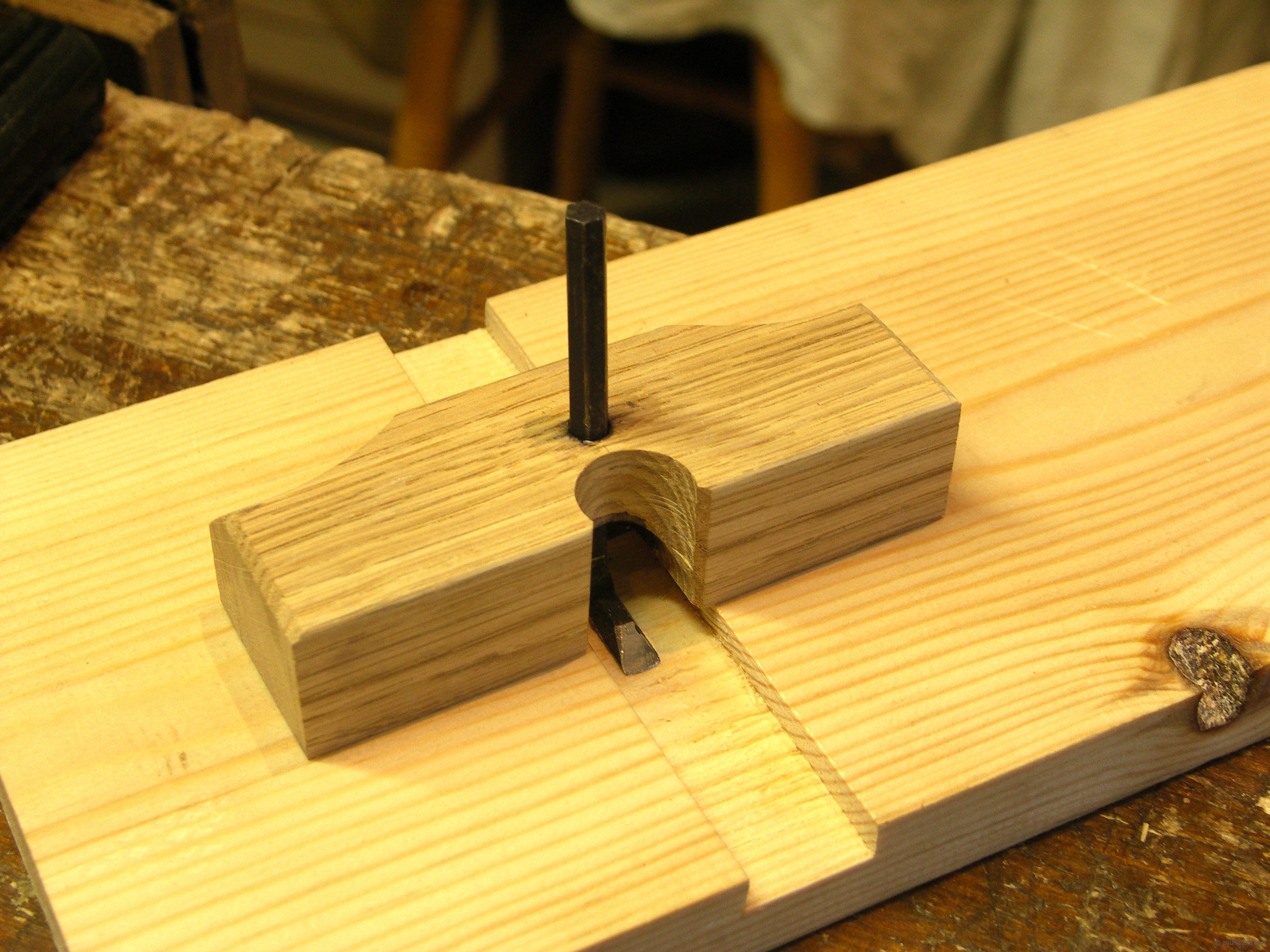

Not so poor man's router - really works!

A more refined 'not-so-poor man’s router.

This is my suggestion for a simple but more advanced not-so-poor man’s router that comes from a small scrap-sized piece of harder wood, oak, (could be softer wood like pine or poplar too) 5-6" long and using only a 1/4" diameter Allen wrench (hex key US) and a slot-headed, threaded bolt.

I first drilled two holes in my blank; the first one, a 1/4" diameter hole centred in the length and 3/4" from one of the long edges. The hole goes all the way through to the other side. The ¼” diameter hole for the wrench should be fairly snug with little slop room.

The second hole, 5/8” diameter, overlaps the opposite edge and is centred 1 3/8” from the same long edge as the ¼” hole. This 5/8” hole is more a sight hole and leads to a second 5/8” hole yet to be drilled to form an escapement for shavings and easy clearance. Stop the drill ½” from the bottom edge.

The second, horizontal hole allows me to see the router cutter and its cut in the housing recess.

As you can see, I ground off the bottom half of the hex key and at a slight angle upwards towards the heel of the wrench. I used a grinding wheel (bench grinder US). This allows free passage in like manner to thoroughbred engineered models. I then ground the top bevel at around 30-degrees to establish the cutting edge.

In this case I used a regular threaded bolt with a thread diameter slightly bigger in diameter than 3/16” to allow securement of the cutting iron at any desired depth and provide future adjustability. I drilled a 3/16” hole through the back of my blank and into the vertical ¼” hole. This allowed me to use the bolt to tap the wall of the hole.

I drilled the second 5/8” diameter overhanging the bottom edge of the blank into the previously drilled 5/8” hole, centres in the ½’ remaining material beneath the vertical hole.

Scallops either side of the cutting iron on the back edge makes the use of the plane more comfortable.

Comments ()