Questions answered #1

Q:

Hi Paul,

I really like that chest and look forward to reading about your next piece in detail.

I make all my workshop tables from either Douglas Fir or White Pine from Home Depot. Unfortunately, HD never labels it as anything but just pine. How critical is the exact type of pine? All I can tell is that it's neither long-leaf nor southern yellow pine.

I am quite intrigued by your comment about workbenches traditionally being made from pine. I can get Douglas Fir or the anonymous white pine but I have a feeling that pine is a better choice as it is soft and splinter free. Any advice on the choice you would make?

Thanks!

A:

You are right, pines vary greatly and the same species will be different depending on where they grow, how high (or low) and elevation they grow at, how dense the forest they are in and so on. On the tool chest in one of the blogs there the annual rings are 1/2" apart and when you work this pine there is only minimal variance in hardness between the two aspects of the growth (annual) ring.

This is North American Eastern White Pine. Oregon pine and Douglas fir do the same in terms of extremely fast growth with no high density in the upper reaches of the taller trees so we no longer have canopied growth but lots of warmth and combining this with the right rainfall and we have extremely fast growth that leads to lots of softer growth aspects in the growth rings. European grown woods don't generally have that issue because we don't have the heat and the forests tend to be denser. This means that we have much slower growth and denser growth rings - upwards of 20 per inch is not uncommon in some of the woods I have come across in the last year.

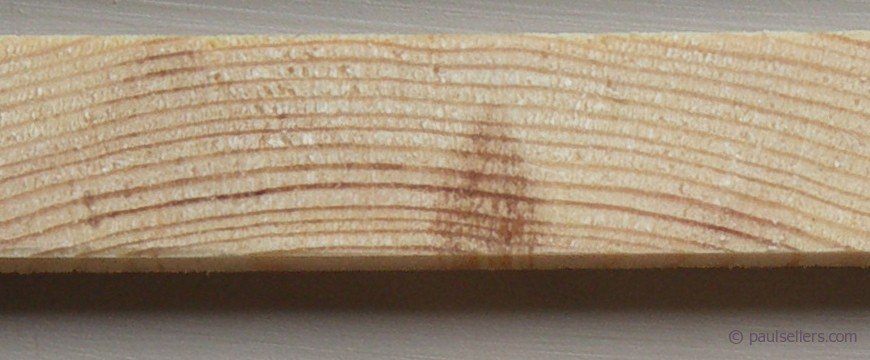

We have redwood pine (which is nothing to do with American redwoods) from the baltic regions of Europe that is very fine pine, much denser than ponderosa pine for instance, quite hard in fact, yet consistent across the growth rings. This section of 3/4" (18mm) has 14 growth rings and is a commonly this rate in most Euro-pines. Some spruces I have had had 35 growth rings in 1" and I have had similar in virgin Longleaf pines salvaged from old US buildings. Second growth Longleaf pine, harvested after the forest were destroyed and the old trees of height irreversibly wiped from the face of the earth, looked identical to Souther yellow pine with its massive growth rings and soft summer wood.

I just received an email from someone in Sweden who said he agreed on the pine benches and had a very old one of his grandfather's shop that was made from good heart pine. I haven't found that hard pine is essential. The advantage of pine for benches is it absorbs the blows and so cushions and supports the workpiece. I have made them from Southern Yellow and Ponderosa, Douglas fir and Oregon pine all with success. I quite like spruce and most often used 2x4 SP&F studs ripped to 3" for bench tops, legs and aprons with the best success of all. Benches I made 18 years ago are still in full service today with no degrade at all and they are used 6 days a week full time. Very stable, once laminated, these benches needed only very minimal surface flattening after six months acclimating in the shop.

Comments ()