Plane evaluation - Lightweight thin-ironed planes really work...

...and they work exceptionally well.

The title says it. Buy #4s and 4 1/2s, 5s and 5 1/2s of the old style Stanleys and Records with impunity. Don't retrofit with thick irons or special cap irons; fettle, flatten and sharpen well and your cheaper plane will work just fine. Forget micro bevels and go for convex cambers and your planes will be easy to sharpen, lighter to use and they will not chatter.

Wow! How is that for going against the flow of popular opinion and the media. Well, it's all true.

Today I used two #4 Stanley planes to flatten and true 6 pieces of oak ranging in size between 1" thick to 4-8" wide and 37" long. The oak had been initially bandsaw cut by the miller and had undulated surfaces and no straight edges or faces. I used other planes but relied on the #4 to test out my feelings that we have dismissed a valuable and well-proven asset in out arsenal of planes. So cheap are these planes secondhand or new that you cannot afford to dismiss owning two or three of them in your plane set.

I threw myself and my two #4 planes into flattening the larger of the oak boards and within four minutes was through all of the bandsaw cut marks and down to a solid oak surface with no bandsaw marks visible. This was using my crowned iron in a #4. Following with the flat, fairly open throated #4 I surface planed the surface and removed all undulations and the surface was truly smooth. I checked for flatness (out of twist) using winding sticks I took down the high points and sighted for hollows or rounds.

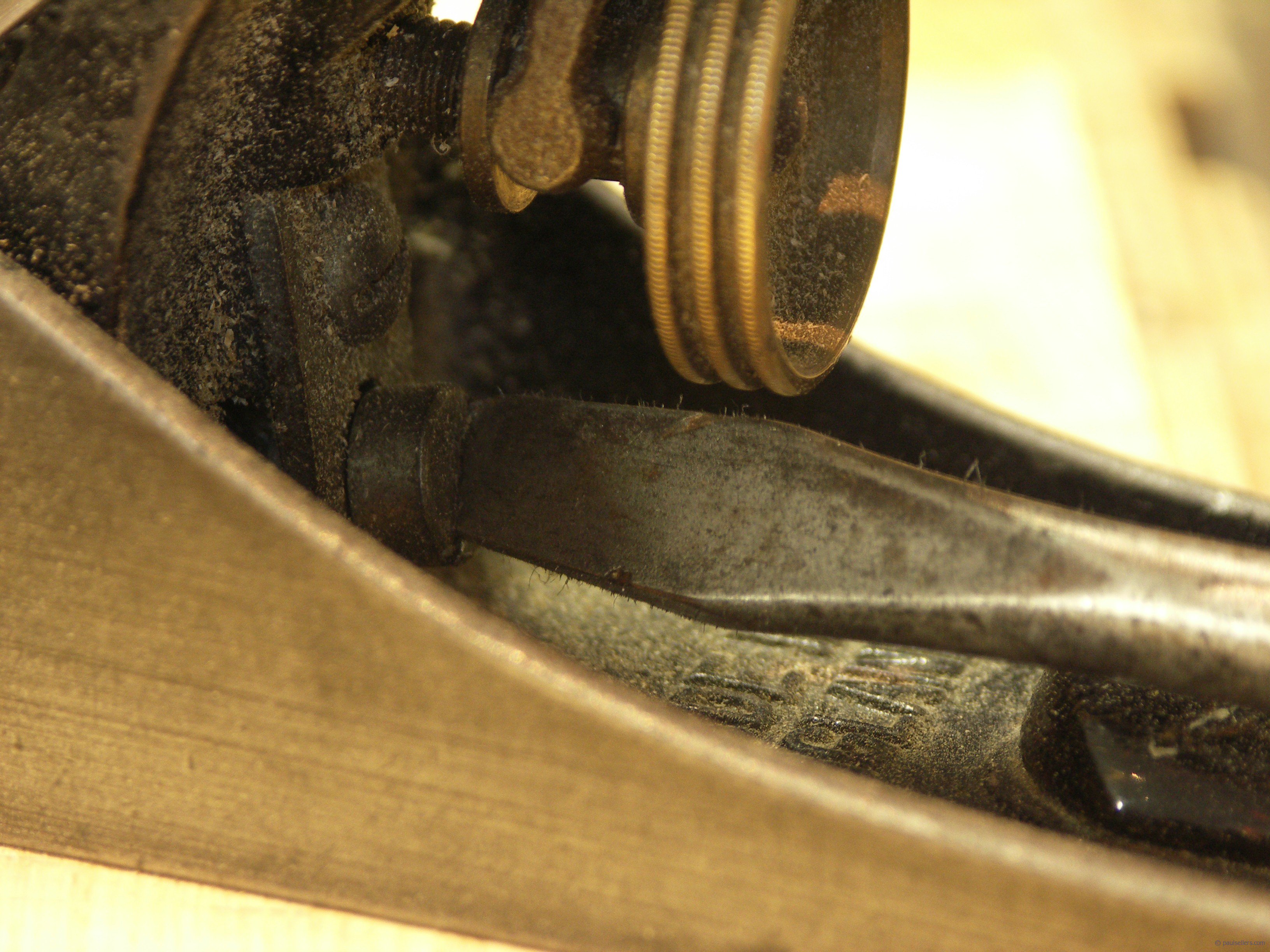

I opened the throat for the initial shaving. To get down through the rougher bandsaw cuts...

...and closed the throat for refining cuts and smoothness.

This is quickly done in the Bailey pattern and without removing the iron or altering the depth set of the plane.

Now this is what I non-scientifically feel in what I did. The #4 was an ordinary #4 fattened and well sharpened by my apprentice, John. I found it light to hand yet in no way wimpy. It never balked at the workload ahead of the cutting iron and surfaced the grain smartly. When the grain was wild and unobliging I simply planed across the grain and resolved the rebellion with ease.

The key ingredient in all of this is sharpness and keeping sharpness by being willing to sharpen when needed. In saying that, I surfaced planed 20 square feet of oak, knots, reverse and wiry grain and all, without the need for a second sharpening and the plane was still sharp when done.

Tomorrow I am weighing some planes I use and used for this testing so you can compare.

Here is another clue for tomorrow's blog. You can adjust the frog on a Bailey frog more easily than you can a Bed Rock. I did that with mine in these planing operations and experienced no shudder, judder, jerking or shirking and definitely no "chatter".

You must remember that heavy planes are not self motivated. Every ounce of bulk and weight touted as advantageous must be countered by the need for additional energy to shove it back and forth. Newton's law of equal and opposite forces prevails. Don't always accept what tool salesmen and tool makers tell you, and tool reviews can scarcely consider themselves impartial if they are selling advertising space. Simply be cautious and if in doubt I will open it up here for balanced discussion.

More about the reality of how frogs work tomorrow.

Comments ()